Frequently asked questions

Company News

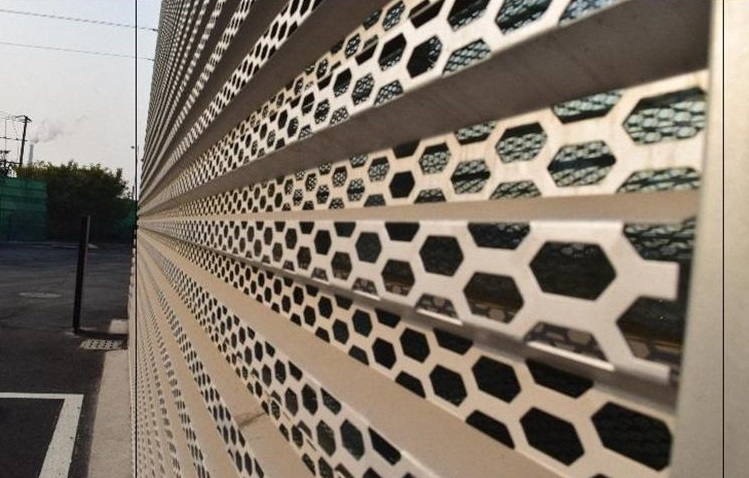

- Unveiling the Charm Space of Punched Aluminum Veneer

- Carved aluminum veneer, a unique landscape of modern architecture

- Punched aluminum veneer: a perfect combination of fashion and practicality

- Aluminum veneer: the fashionable choice for modern architecture

- Aluminum veneer customization, creating a unique spatial aesthetic

Industry dynamics

- Carved aluminum veneer, creating a new trend of fashionable home furnishings

- What are the maintenance costs for aluminum veneer after installation?

- Fluorocarbon aluminum veneer: the 'invisible hero' of modern architecture

- How to better choose aluminum veneer based on its classification and specifications

- Energy saving and environmental protection characteristics of curtain wall aluminum veneer

Frequently asked questions

- How to solve the environmental problems in the production process of aluminum veneer?

- How to distinguish the quality of aluminum veneer?

- How to use and maintain aluminum veneer reasonably?

- How to design customized aluminum veneer?

- How to determine the quantity and size of customized aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

How to solve the environmental problems in the production process of aluminum veneer?

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: February 26, 2025 21:43:22

- Click:0

How to solve itAluminum veneerEnvironmental issues in the production process?

With the continuous improvement of people's requirements for the appearance of buildings, aluminum veneer has become a popular material in the field of architecture today. However, there are some environmental issues in the production process of aluminum veneer, such as exhaust gas, solid waste, and energy consumption. This article will explore how to solve environmental issues in the production process of aluminum veneer from four aspects.

1、 Raw material selection

The production of aluminum veneer requires a large amount of aluminum material. In terms of raw material selection, high-quality, low-carbon, and environmentally friendly aluminum materials should be chosen, and energy-saving processing equipment should be used to reduce emissions of exhaust gas, wastewater, and solid waste. In addition, the raw material procurement plan should be tailored according to the actual situation of the manufacturer to avoid excessive procurement and waste.

Secondly, in the production process of aluminum veneer, other materials such as coatings and adhesives used should also comply with environmental standards to reduce their impact on the environment.

2、 Wastewater treatment

During the production process of aluminum veneer, a large amount of wastewater is generated. In order to reduce the impact of wastewater on the environment, professional wastewater treatment equipment should be used to treat and filter the generated wastewater, ensuring that the discharged wastewater meets relevant national environmental standards.

At the same time, manufacturers can utilize advanced technology and adopt zero discharge methods to reduce wastewater generation, such as using technologies such as circulating water treatment systems.

3、 Energy consumption control

The production process of aluminum veneer requires a large amount of energy, including electricity, gas, etc. In order to reduce energy consumption, manufacturers should adopt energy-saving equipment and regularly inspect and maintain the equipment to ensure its efficient operation. At the same time, an intelligent monitoring system is adopted to monitor the energy consumption of equipment in real time, optimize the production process, and minimize unnecessary energy consumption as much as possible.

4、 Waste gas treatment

During the production process of aluminum veneer, a large amount of exhaust gas is generated. In order to avoid environmental pollution caused by exhaust gas, effective exhaust gas treatment measures should be taken, such as using efficient purification equipment to treat exhaust gas. At the same time, closed production can be adopted in the production process to reduce the generation of exhaust gas and avoid the leakage of exhaust gas.

5、 Summary

In summary, in order to solve the environmental problems in the production process of aluminum veneer, manufacturers should start from four aspects: raw material selection, wastewater treatment, energy consumption control, and exhaust gas treatment, and take corresponding environmental protection measures. Through these efforts, we can reduce environmental pollution and achieve sustainable development.

- previous page:How to distinguish the quality of aluminum veneer?

- Next page:How to use aluminum veneer for innovative design?

Customer service QQ

Customer service QQ