Frequently asked questions

Company News

- Lightweight perforated aluminum veneer, the new favorite of fashionable home decor!

- Aluminum veneer: the "light luxury" choice in architectural aesthetics

- Aluminum veneer: the fashion darling of the construction industry, environmentally friendly and durable

- Carved aluminum veneer: the unique charm of modern architecture

- Aluminum veneer customization: an artistic journey to create personalized spaces

Industry dynamics

- The mystery of the durability and sturdiness of aluminum veneer for curtain walls

- Customized aluminum veneer manufacturers offer affordable prices and guaranteed quality through direct sales

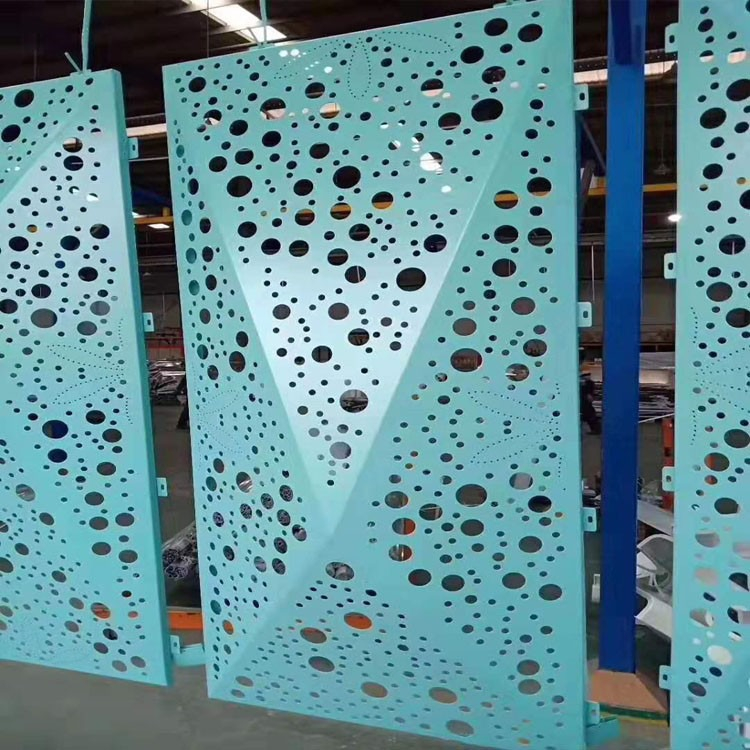

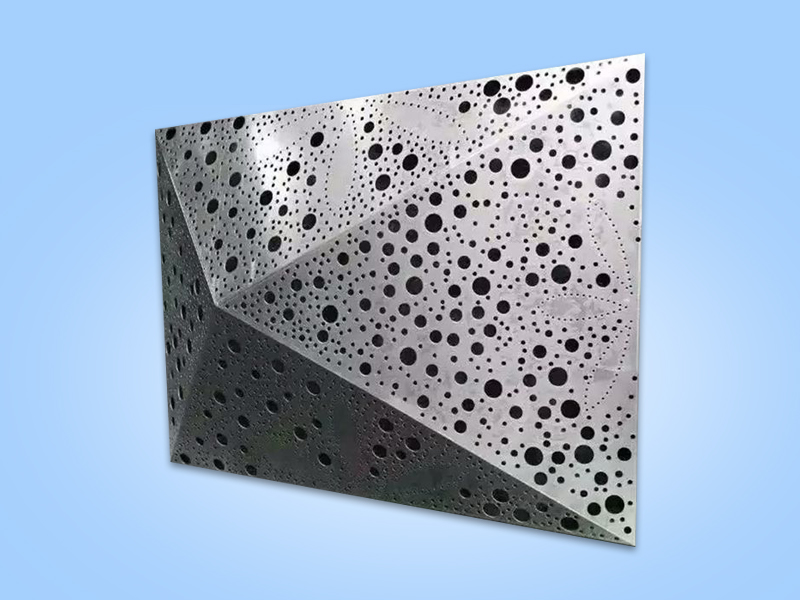

- Punched aluminum veneer: the "breathing window" of modern architecture

- Punched aluminum veneer, the new favorite of modern architectural aesthetics!

- Aluminum veneer customization, creating a new trend of personalized space

Frequently asked questions

- How to determine the quantity and size of customized aluminum veneer?

- How to distinguish the quality of aluminum veneer?

- How to design customized aluminum veneer?

- How to use and maintain aluminum veneer reasonably?

- How to identify the quality of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

How to improve the fire resistance of aluminum veneer?

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: February 24, 2025 06:14:01

- Click:0

How to improveAluminum veneerFire resistance performance?

Summary:

This article aims to discuss how to improve the fire resistance of aluminum veneer. Provide a detailed explanation from four aspects: material selection, fireproof coating, installation system, and maintenance measures, in order to provide effective solutions.

1、 Material selection

1. Reasonable selection of metal alloys:

The fire resistance of aluminum veneer material is closely related to the selected metal alloy composition. Aluminum alloys with high melting points and good high-temperature resistance, such as aluminum magnesium alloys and aluminum manganese alloys, should be preferred. This can greatly improve the fire resistance of aluminum veneer.

2. Increase the content of flame retardants:

Adding flame retardants is a common method in the production process of aluminum veneer to improve its fire resistance. Flame retardants can effectively prevent the spread of flames and slow down the combustion rate of aluminum veneers. Therefore, in the process of material selection, priority should be given to adding an appropriate amount of flame retardant to improve the fire rating of aluminum veneer.

3. Strengthening material surface treatment:

The surface treatment of aluminum veneer plays a crucial role in its fire resistance performance. Through special surface coating and treatment processes, a dense oxide film can be formed, which not only improves the oxidation resistance of aluminum veneer, but also enhances its fire resistance to a certain extent.

2、 Fireproof coating

1. Choose professional fire-resistant coating products:

Choosing the appropriate fire-resistant coating product is crucial for aluminum veneer. Professional fireproof coatings can provide effective fire protection, forming a layer of fire-resistant film to prevent the spread of flames. Therefore, during the construction process, fireproof coating products with good fire resistance and weather resistance should be selected to ensure that the fire resistance of aluminum veneer meets the standard requirements.

2. Strengthen the adhesion of the coating:

The fireproof coating of aluminum veneer must have good adhesion to ensure its long-term stability. In order to increase the adhesion between the coating and the aluminum veneer, methods such as sanding and anodizing can be used to form a strong bond between the coating and the aluminum veneer, thereby improving the fire resistance of the aluminum veneer.

3. Regular inspection and maintenance:

In order to ensure that the fireproof coating of aluminum veneer is always in good condition, regular testing and maintenance should be carried out. Timely repair of damaged parts of the coating to maintain its integrity can improve the effectiveness of the fireproof coating and enhance the fire resistance of aluminum veneer.

3、 Install the system

1. Reasonable installation structure design:

In the installation process of aluminum veneer, attention should be paid to reasonable installation structure design. Adopting appropriate installation systems, such as suspended installation systems or plug-in installation systems, can effectively reduce the fire risk of aluminum veneer. By increasing the number of fixed points and setting up suspension devices reasonably, the overall stability and fire resistance of aluminum veneer can be improved.

2. Ensure safe insulation layer:

During the installation process of aluminum veneer, a fire-resistant insulation layer should be equipped. The insulation layer not only serves as a thermal insulation layer, but also effectively prevents the spread of flames. Therefore, during the installation process, suitable insulation materials should be selected and ensured to comply with relevant fire safety standards.

3. Strictly adhere to safety construction regulations:

In order to ensure the safety and fire resistance of aluminum veneer, the construction unit should strictly comply with relevant safety construction specifications and operating procedures. During the installation process, necessary fire prevention measures should be taken, such as setting up fire extinguishers, sprinkler systems, etc., to cope with sudden fire incidents.

4、 Maintenance measures

1. Regular cleaning and inspection:

Regular cleaning and inspection of aluminum veneer is one of the important measures to maintain its fire resistance performance. By regularly cleaning the dust and dirt on the surface of aluminum veneer, its good reflective performance can be maintained and the fire prevention effect can be improved.

2. Timely handling of damaged parts:

If damage or deformation is found in the aluminum veneer, it should be repaired or replaced in a timely manner. Damaged aluminum veneer may reduce the overall fire resistance, so it is very important to deal with the damaged parts in a timely manner.

3. Regular fire drills:

Regular fire drills can improve personnel's ability to respond to fires and enhance their understanding of the fire resistance performance of aluminum veneer. Through drills, potential safety hazards can be identified and corresponding measures can be taken to improve fire prevention performance.

5、 Summary:

In summary, improving the fire resistance of aluminum veneer requires starting from multiple aspects such as material selection, fireproof coating, installation system, and maintenance measures. Reasonable selection of metal alloys, use of professional fireproof coatings, adoption of reasonable installation systems, and regular testing and maintenance are all effective methods to improve the fire resistance of aluminum veneer. Only by considering these factors comprehensively can we ensure that the fire resistance of aluminum veneer achieves the expected effect.

- previous page:How to improve the insulation performance of aluminum veneer?

- Next page: No more

Customer service QQ

Customer service QQ