Frequently asked questions

Company News

- The market trend of customized aluminum veneer: constantly expanding consumer demand

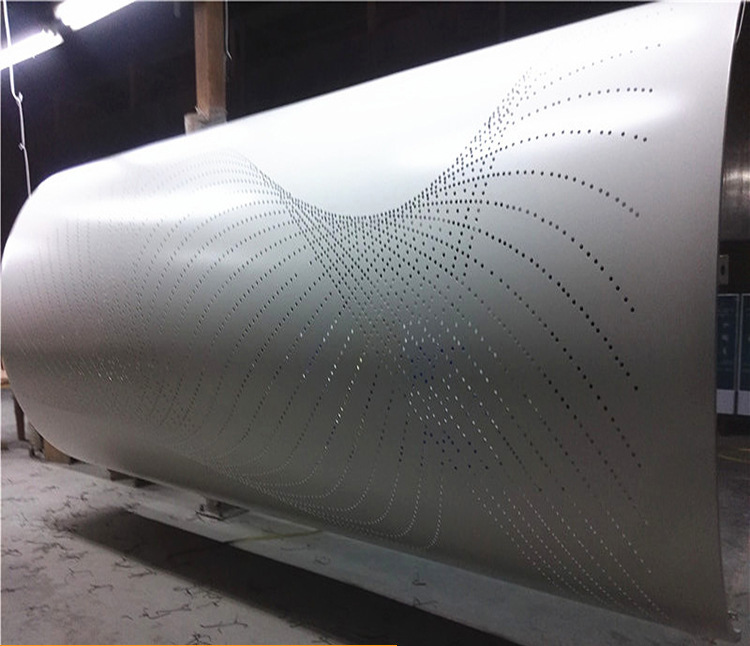

- Unlimited creativity, perforated aluminum veneer takes you into the world of art

- The Fantasy Journey of Aluminum Veneer: From Birth to Wide Application

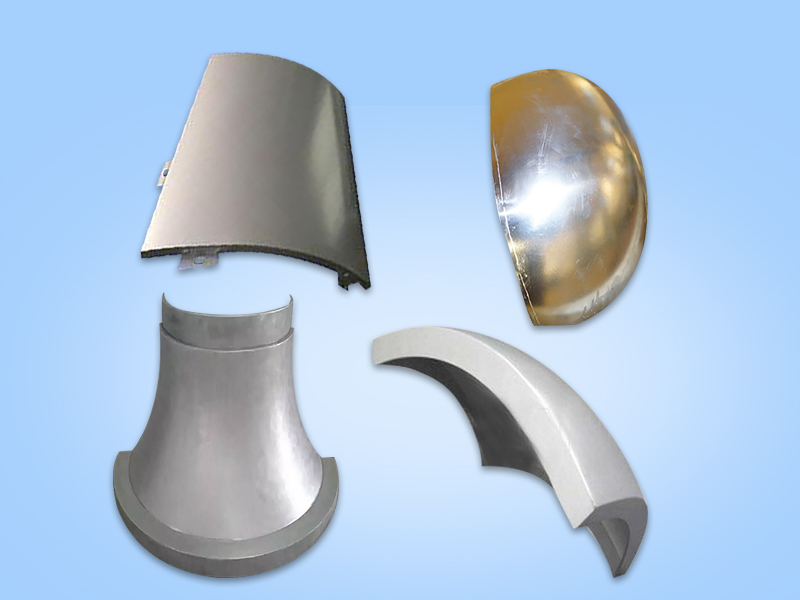

- Aluminum veneer: lightweight building material, shaping the beauty of modern architecture

- Carved aluminum veneer: a magnificent turn of aluminum art

Industry dynamics

- Aluminum veneer customization, creating a unique home style new trend

- Aluminum veneer customization, creating a new trend of personalized space

- Sharing of installation techniques for engineering fluorocarbon aluminum veneer

- Aluminum veneer: the beauty of industry, the charm of details

- What are the advantages and disadvantages of aluminum veneer?

Frequently asked questions

- How to determine the quantity and size of customized aluminum veneer?

- How to store and transport aluminum veneer?

- How to solve the environmental problems in the production process of aluminum veneer?

- How to improve the fire resistance of aluminum veneer?

- How to distinguish the quality of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

How to identify the quality of aluminum veneer?

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: February 25, 2025 18:19:26

- Click:0

1、 Surface treatment

1. Appearance inspection

The appearance of aluminum veneer should be flat and smooth, without obvious bumps or bubbles. Carefully observe the surface for scratches, oxidation, or uneven color.

2. Coating quality

Coating quality is an important indicator for judging the quality of aluminum veneer. The coating should be uniform, firm, and free from peeling or blistering. You can gently scratch the surface of the coating with your fingers, and good quality will have a certain degree of scratch resistance.

3. Weather resistance test

Conducting weather resistance testing can determine whether aluminum veneer has good oxidation and corrosion resistance. The sample can be exposed to an outdoor environment to observe whether its color changes, surface oxidation or corrosion occurs, and other issues.

2、 Thickness specification

1. Measure thickness

Use professional measuring tools such as micrometers or ultrasonic thickness gauges to measure the thickness of aluminum veneer. Qualified aluminum veneer should meet the requirements in the design specifications, and the deviation should not be too large.

2. Compare weight

Aluminum veneers of the same size with lighter weight often indicate poorer aluminum material quality. By comparing the weight of different aluminum veneers, the quality of their aluminum materials can be preliminarily judged.

3. Structural stability

The structural stability of aluminum veneer is an important indicator of its quality. You can gently tap the aluminum veneer with your hand. High quality aluminum veneer will produce a crisp sound, while low-quality aluminum veneer will produce a muffled sound.

3、 Coating

1. Material selection

High quality coating materials have good weather resistance, corrosion resistance, and wear resistance. The quality of the coating can be determined by querying the product material information and relevant certifications provided by the manufacturer.

2. Color uniformity

The color of the coating should be uniform and consistent, without any significant color difference. You can observe the surface of the aluminum veneer under sunlight to check if the color is uniform.

3. Adhesion test

Use professional adhesion testing equipment to test the coating to determine if its adhesion meets the requirements. High quality coatings should have strong adhesion and not easily peel off.

4、 Production process

1. Production equipment

Observing the production equipment of aluminum veneer manufacturers, high-quality production equipment can ensure the production quality of aluminum veneer. Advanced equipment will make the production of aluminum veneer more refined, which is beneficial for improving product quality.

2. Production process

Understand the production process and workflow of aluminum veneer manufacturers, including the selection of alloy materials, surface treatment, coating technology, etc. By understanding the manufacturing process, one can better assess the quality of the product.

3. Quality certification

High quality aluminum veneer manufacturers usually have relevant quality certifications, such as ISO9001. Querying and verifying relevant certifications and qualifications can further determine the quality of aluminum veneer.

5、 Summary:

By identifying the surface treatment, thickness specifications, coating, and production process of aluminum veneer, we can comprehensively understand the quality status of aluminum veneer. When selecting aluminum veneer, it is recommended to consider the above aspects comprehensively and choose aluminum veneer products that are reliable in quality and meet the requirements.

Customer service QQ

Customer service QQ