Industry information

Company News

- Aluminum veneer customization: an artistic journey to create personalized spaces

- Infinite creativity, perforated aluminum veneer interprets the beauty of modern art

- Aluminum veneer customization, creating a new trend of personalized space

- Aluminum veneer: the "silver coat" of modern architecture

- Fluorocarbon aluminum veneer: the new favorite of aluminum materials and the fashionable choice for modern architecture

Industry dynamics

- Manufacturing process and characteristics of aluminum alloy air conditioning protective cover

- Common problems and solutions for customized aluminum veneer

- Aluminum veneer new trend: the beauty of lightness, the fashionable choice for modern architecture

- Aluminum veneer punching, perfect integration of art and craftsmanship

- What is the fire resistance of fluorocarbon aluminum veneer?

Frequently asked questions

- How to solve the environmental problems in the production process of aluminum veneer?

- How to determine the quantity and size of customized aluminum veneer?

- How to distinguish the quality of aluminum veneer?

- How to design customized aluminum veneer?

- How to use and maintain aluminum veneer reasonably?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

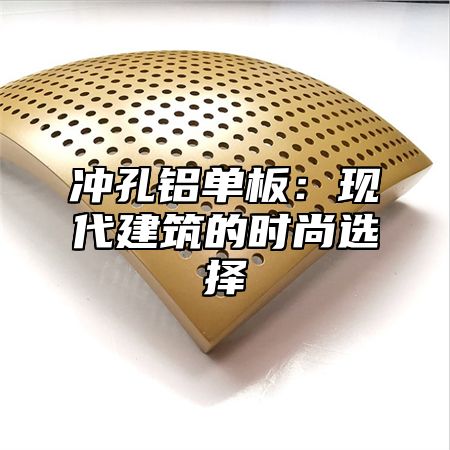

Punched aluminum veneer: a fashionable choice for modern architecture

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: February 28, 2025 13:19:43

- Click:0

Dear friends in the architecture industry, today we will talk about a treasure that makes modern architecture more fashionable - punching holesAluminum veneerDoes this name sound a bit high-end? Don't worry, listen to me slowly.

We need to understand that punched aluminum veneer is actually formed by special processing of aluminum plates. It has a smooth surface and a rich texture, and most importantly, it has those small holes on it, which is the origin of its name. These holes not only enhance the aesthetic appeal of the board, but also serve as ventilation and heat dissipation. Isn't it amazing?

I first came into contact with punched aluminum veneer at the construction company where I work. At that time, we took on a design project for a shopping mall, and the client specifically requested the use of this material. At that time, I was quite puzzled. What kind of magic does this punched aluminum veneer have to make the client so fond?

Later, as the project progressed, I gradually understood the charm of punched aluminum veneer. It comes in a wide range of colors, from solid to gradient, to meet various design needs. Its surface treatment process is diverse, which can meet the needs of various styles. We can make perforated aluminum veneer into frosted, painted, oxidized and other effects to make the appearance of the building more colorful.

Let's talk about its performance again. Punched aluminum veneer has excellent weather resistance and corrosion resistance, and can maintain good performance even in harsh weather environments. Its fire resistance is also quite good, which is undoubtedly a plus point for building safety.

The application range of punched aluminum veneer is also very wide. It can be used not only for public buildings such as shopping malls and office buildings, but also for private buildings such as residences and hotels. Even in some special occasions, such as exhibition halls, museums, etc., perforated aluminum veneer can also exert its unique charm.

How is punched aluminum veneer made? Its production process is not complicated. Cut and drill the aluminum plate, and then perform surface treatment. Although this process is simple, each step requires precise operation to ensure the quality of punched aluminum veneer.

During the production process, we need to pay attention to the following points:

1. Drilling: The size, spacing, shape, etc. of the holes need to be determined according to the design requirements to ensure both aesthetics and practicality.

2. Surface treatment: The choice of surface treatment process should be determined based on the architectural style and functional requirements to achieve the best results.

3. Quality control: During the production process, it is necessary to strictly control the quality of each link to ensure the quality of punched aluminum veneer.

Speaking of which, I remembered an interesting story. Once, our company took on a villa design project, and the client requested the use of punched aluminum veneer. During the production process, we encountered a difficult problem: how to make punched aluminum veneer present a dreamy effect under sunlight?

To solve this problem, our team has invested a lot of time and effort. We have tried various solutions, and under the clever conception of the designer, we have adopted a special spray painting process to create a dreamy visual effect on the punched aluminum veneer when exposed to sunlight. After seeing the finished product, Party A praised our design proposal endlessly.

Through this case, we can see that punched aluminum veneer, with the clever use of designers, can create countless possibilities. It not only makes the building more beautiful, but also enhances its functionality.

Punched aluminum veneer also has its shortcomings. It has a relatively high price and a complex installation process. Compared to its advantages, these shortcomings are acceptable.

Punched aluminum veneer, as a fashionable choice in modern architecture, has become the darling of more and more designers. I believe that in the future field of architecture, it will play a greater role.

What I want to say is that architecture is not just cold reinforced concrete, but also a work of art carefully crafted by designers. And punched aluminum veneer is an indispensable part of this artwork. Let's look forward to the future of perforated aluminum veneer shining even brighter in the field of architecture!

Customer service QQ

Customer service QQ