Industry information

Company News

- Aluminum veneer customization, creating a new trend of personalized space

- Fluorocarbon aluminum veneer: the new darling of the construction industry, environmentally friendly and fashionable!

- Aluminum veneer customization, creating a new trend of personalized space

- Aluminum veneer: an innovative material for architectural aesthetics

- Aluminum veneer: not only a building material, but also the soul of architecture

Industry dynamics

- Aluminum veneer customization, creating a new trend of personalized space

- Color selection and customization plan for 2mm aluminum veneer

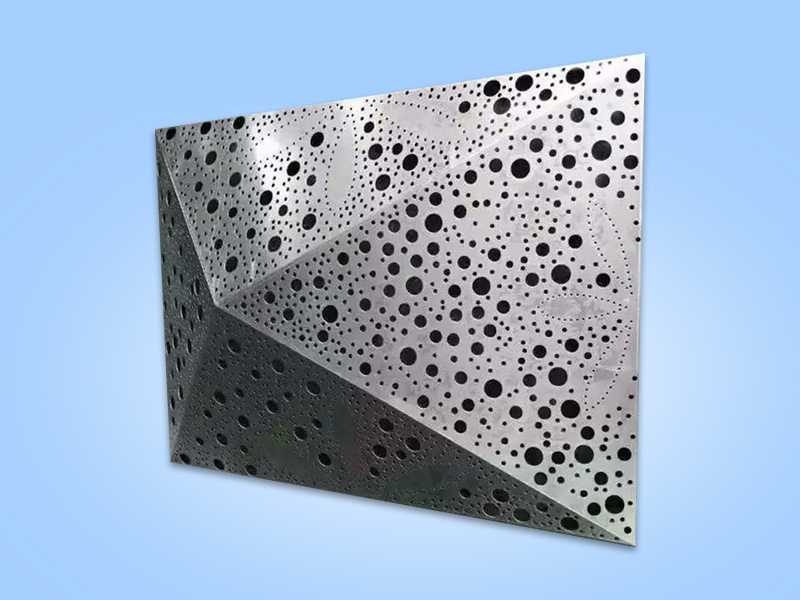

- Punched aluminum veneer: an aesthetic weapon for modern architecture

- Fluorocarbon aluminum veneer, the 'hidden hero' of modern architecture

- Interpretation of Market Regulation on the Price and Supply Demand Relationship of Aluminum Veneer

Frequently asked questions

- How to distinguish the quality of aluminum veneer?

- How to store and transport aluminum veneer?

- How to improve the fire resistance of aluminum veneer?

- How to use and maintain aluminum veneer reasonably?

- How to use aluminum veneer for innovative design?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Research on Manufacturing Process and Application of Aluminum Alloy Air Conditioning Protective Cover

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: February 20, 2025 15:19:39

- Click:0

With the acceleration of urbanization and the improvement of people's living standards, air conditioning has become an indispensable part of modern life. The long-term exposure of outdoor air conditioning units to natural factors such as sunlight, rain, and wind erosion can easily lead to damage and aging, causing great inconvenience to people's daily lives. In order to solve this problem, aluminum alloy air conditioning protective covers have emerged and become a popular building material in the market. Below, we will provide a detailed introduction to aluminum alloy air conditioning protective covers from two aspects: manufacturing processes and application research.

1、 Manufacturing process

Aluminum alloy air conditioning protective cover is a new type of building material with excellent performance and characteristics. Its manufacturing process mainly includes the following steps:

1. Design drawing: Based on customer needs and actual situations, design drawings are made to determine the size, shape, and material parameters of the aluminum alloy air conditioning protective cover.

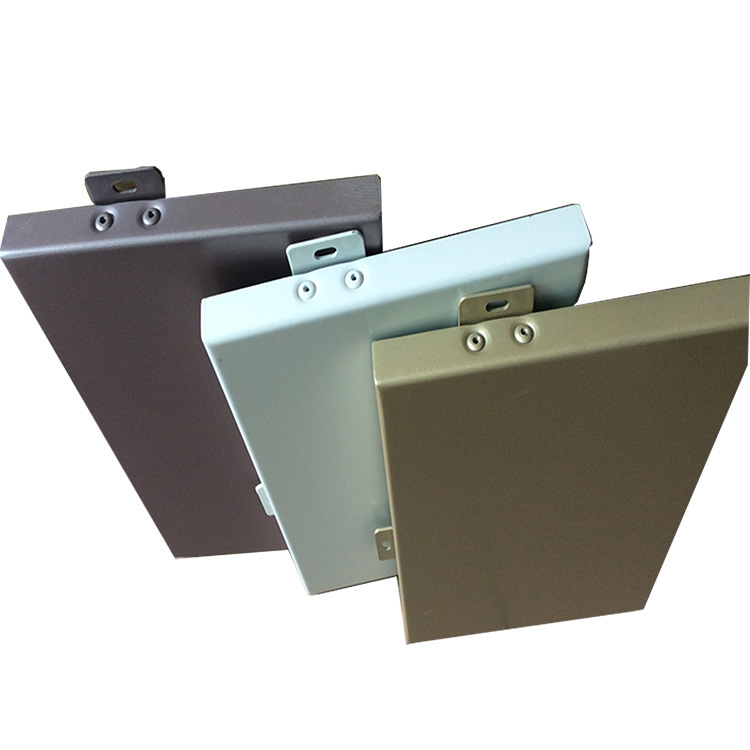

2. Cutting and processing: Cut and process aluminum materials according to the design drawings to produce the required aluminum alloy sheets, pipes, and other components.

3. Welding assembly: Assemble aluminum alloy sheets, pipes, and other components into a complete structure through welding, riveting, and other methods.

4. Surface treatment: Surface treatment of aluminum alloy air conditioning protective covers, such as painting, anodizing, etc., to increase their corrosion resistance and aesthetics.

2、 Applied research

The application range of aluminum alloy air conditioning protective cover is very wide, mainly used in the following aspects:

1. Construction industry: Aluminum alloy air conditioning protective covers can be used as part of the exterior decoration materials of buildings, beautifying the appearance of the building while also protecting the outdoor unit of the air conditioner.

2. Residential communities: Aluminum alloy air conditioning protective covers can be installed on outdoor units of air conditioning in residential communities to provide protection and beautify the community environment.

3. Other places: Aluminum alloy air conditioning protective covers can also be used on other equipment and items that need protection, such as streetlight poles, cable trays, etc.

3、 Summary

By studying the manufacturing process and application research of aluminum alloy air conditioning protective covers, we can better understand the manufacturing process and application fields of this new building material. Only by deeply understanding its manufacturing process and application situation can we better choose and use this material, and contribute to our environmental protection cause.

Customer service QQ

Customer service QQ