Corporate News

Company News

- Aluminum veneer customization, creating a new trend of personalized space!

- Aluminum veneer: understated luxury in modern architecture

- Aluminum veneer: the 'hidden protagonist' of modern architecture

- Customize aluminum veneer to create personalized space art

- Fluorocarbon aluminum veneer: a fashionable outerwear for modern architecture

Industry dynamics

- The magnificent transformation of carved aluminum veneer creates a personalized space!

- Fluorocarbon aluminum veneer: the green new favorite of modern architecture

- The development trend of aluminum veneer production technology and its application prospects in the industry

- Modern architecture uses twisted aluminum veneer to give new life to buildings

- Environmental protection and aesthetics of aluminum veneer

Frequently asked questions

- How to identify the quality of aluminum veneer?

- How to store and transport aluminum veneer?

- How to use and maintain aluminum veneer reasonably?

- How to improve the insulation performance of aluminum veneer?

- How to use aluminum veneer for innovative design?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Detail processing for customized aluminum veneer: creating a perfect decorative effect

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: February 24, 2025 11:16:25

- Click:0

Summary:Aluminum veneerCustomization is a common decorative material, and its attention to detail is crucial in creating a perfect decorative effect. This article will elaborate on the details of customized aluminum veneer from four aspects, including design planning, material selection, processing technology, and installation and construction.

1、 Design Planning

1. Reasonable layout design: In the process of customizing aluminum veneer, the first step is to carry out a reasonable layout design. Determine the installation position and quantity of aluminum veneer according to the requirements of decoration and the characteristics of the space, in order to achieve the best decorative effect.

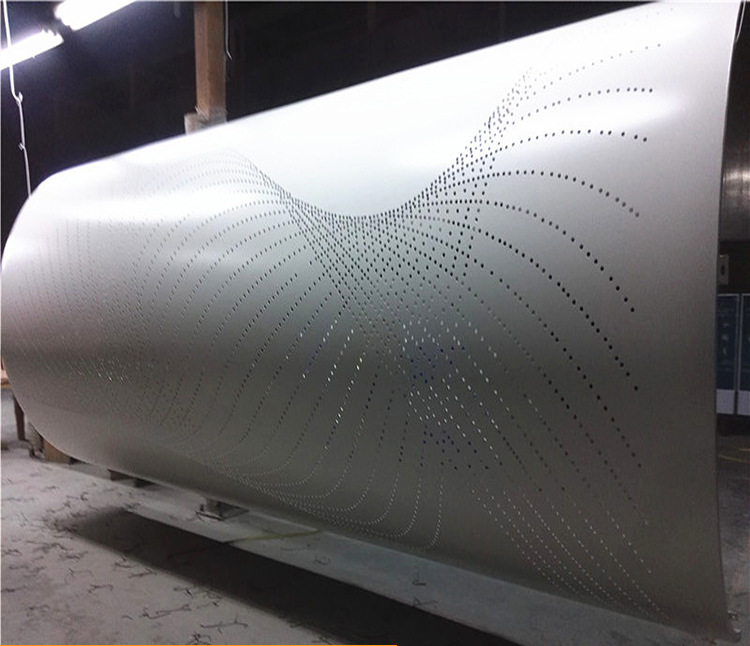

2. Personalized creative design: The detail processing of customized aluminum veneer also includes personalized creative design. By utilizing innovative design concepts, patterns, and color combinations, aluminum veneer becomes a highlight of decoration and enhances the overall effect.

3. Accurate size measurement: Accurate size measurement is a crucial step in the customization of details for aluminum veneer. Only by accurately grasping the size of the decorative space can we ensure the precise matching of aluminum veneer during installation, thereby achieving a perfect decorative effect.

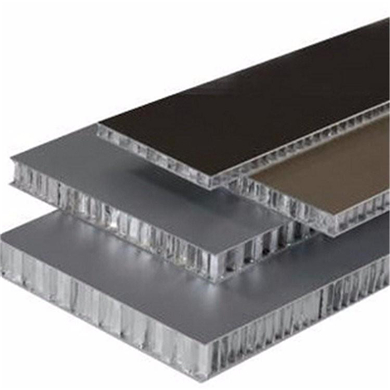

2、 Material selection

1. Quality assurance: In the process of customizing aluminum veneer, selecting high-quality materials is the key to ensuring the decorative effect. High quality aluminum materials have good corrosion resistance and strength, which can ensure the stability and durability of decorative panels.

2. Surface treatment: When selecting aluminum veneer materials, attention should also be paid to their surface treatment. Common treatment methods include anodizing, spraying, and electrophoretic coating, which can enhance the surface hardness and corrosion resistance of aluminum veneer, making it more suitable for different decorative environments.

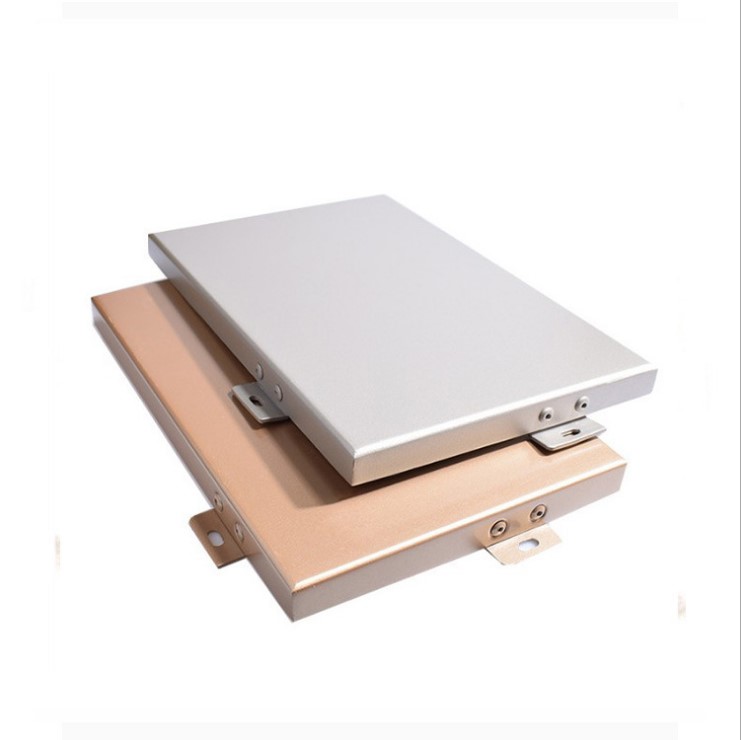

3. Accessory matching: In addition to the material selection of the aluminum veneer itself, the choice of accessories is also very important. Appropriate accessories can achieve the connection, fixation, and decorative details of aluminum veneer, enhancing the overall decorative effect.

3、 Processing technology

1. Cutting and Forming: Aluminum veneer customization requires cutting and forming to adapt to different application scenarios. By using advanced CNC cutting equipment and forming processes, the precise processing of aluminum veneer can be ensured, seamlessly connecting it with the decorative environment.

2. Surface treatment: In addition to surface treatment of materials, processing techniques also include additional surface treatment of aluminum veneers. For example, texture, color, and pattern can be created to enhance the decorative effect of aluminum veneer.

3. Anti corrosion coating: During the processing of aluminum veneer, anti-corrosion coating treatment is also required. This step can improve the corrosion resistance of aluminum veneer, extend its service life, and maintain the stability of the decorative effect.

4、 Installation and construction

1. Accurate measurement and marking: Installation construction is the final step in customizing aluminum veneer, requiring precise measurement and marking. Only by accurately grasping the size and shape of the decorative space can we ensure the correct installation position and precise fit of the aluminum veneer.

2. Standardized construction methods: During the installation and construction process, it is necessary to follow standardized operating procedures and construction methods. Reasonably arrange construction personnel, select appropriate installation tools, ensure the stable fixation of aluminum veneer, and maintain the cleanliness and smoothness of decorative panels.

3. Quality inspection and maintenance: The detailed processing of customized aluminum veneer not only includes the installation process, but also requires quality inspection and maintenance. Conduct quality inspections on the installed aluminum veneer, promptly address any issues that arise, and perform routine maintenance to maintain the durability of the decorative effect.

5、 Summary:

The detail processing of customized aluminum veneer plays a crucial role in creating a perfect decorative effect. Through reasonable design planning, material selection, processing technology, and installation construction, aluminum veneer can fully demonstrate its personalized and decorative effects, creating an ideal atmosphere for the space. In the future customization of aluminum veneer, continuous exploration and innovation are needed to improve the quality and level of detail processing, in order to meet people's pursuit of a better life.

Customer service QQ

Customer service QQ