Corporate News

Company News

- Fluorocarbon aluminum veneer: a new favorite in architecture and a new trend in environmental protection

- Punched aluminum veneer: the finishing touch of architectural aesthetics

- Fluorocarbon aluminum veneer: the "new favorite" of future building materials

- Aluminum veneer: the 'hidden protagonist' of modern architecture

- Punched aluminum veneer: the new favorite for creating fashionable spaces

Industry dynamics

- Indoor and outdoor decorative perforated aluminum veneer

- Exquisite fluorocarbon curved aluminum veneer showcases architectural charm

- How can aluminum veneer elevate the architectural grade?

- Aluminum veneer: a fashionable outerwear for industrial buildings

- Punched aluminum veneer: the new favorite of modern architecture, just as beautiful!

Frequently asked questions

- How to store and transport aluminum veneer?

- How to design customized aluminum veneer?

- How to identify the quality of aluminum veneer?

- How to use and maintain aluminum veneer reasonably?

- How to distinguish the quality of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Detail processing of customized aluminum veneer: exquisite and meticulous, showcasing excellent quality

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: February 20, 2025 19:48:42

- Click:0

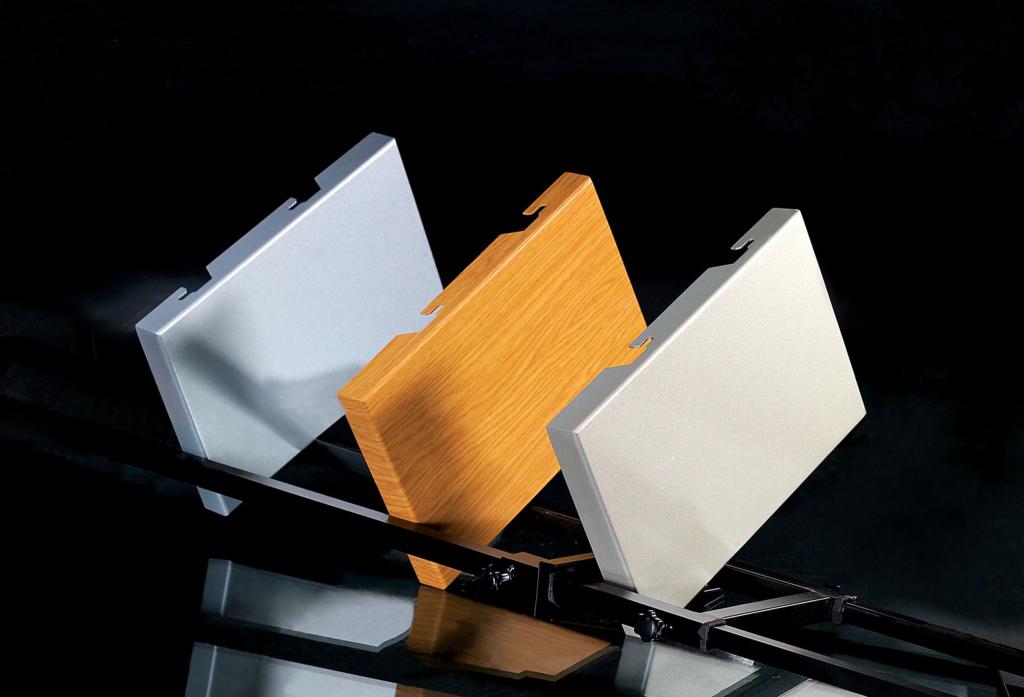

1、 Color matching

In the process of customizing aluminum veneer, color matching is one of the crucial details. Color matching should consider the consistency between the overall style of the building's exterior walls and the interior decoration style. At the same time, corresponding colors should be selected based on factors such as the surrounding environment, natural light, and climate of the building to achieve harmony and unity with the surrounding environment. In addition, zoning coloring can be performed according to different areas to make the overall effect of the building more perfect.

When choosing colors, it is also important to pay attention to color differences. Generally speaking, there are two types of surface coatings for aluminum veneer: air spraying and gloss treatment. The coating thickness and surface brightness vary, which can easily cause color differences. At this point, it is very necessary to choose a professional aluminum veneer manufacturer, who will conduct strict color difference control to ensure color consistency.

Finally, color matching should also take into account changes in the surrounding environment. Over time, the appearance and surrounding environment of buildings will change, and the selection of colors needs to be considered long-term to prevent the need for secondary processing in the future.

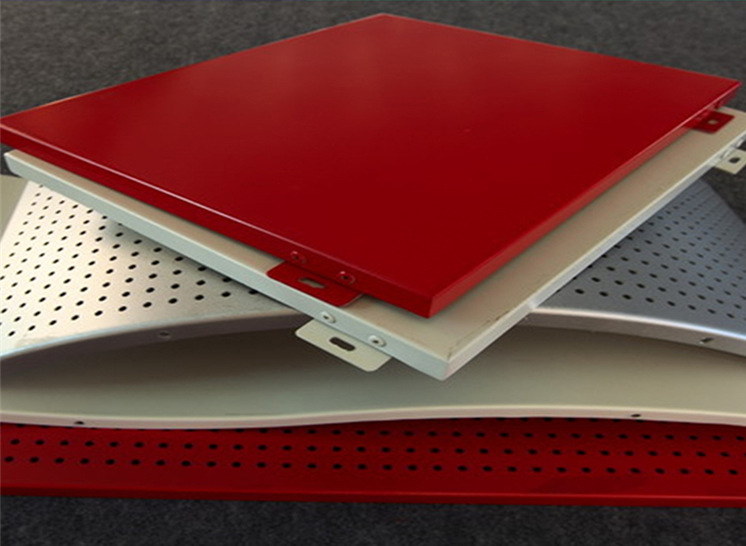

2、 Surface treatment

Surface treatment is another important factor affecting the quality of aluminum veneer. In the process of surface treatment of veneer, regardless of which process is selected, the following aspects should be noted.

Firstly, the flatness. Considering that aluminum veneer is a highly plastic material that is prone to deformation under stress, attention should be paid to controlling its flatness in surface treatment to avoid serious problems such as bending, indentation, and peeling.

Next is surface hardness. There are many factors that affect surface hardness, such as coating thickness, material hardness, and spray gun distance. Manufacturers should strive to improve surface hardness and wear resistance as much as possible when selecting materials and processes, in order to make the surface of aluminum veneer more sturdy and durable.

Finally, there is the surface color. The selection of surface treatment materials for aluminum veneer will have a direct impact on its color. To ensure the stability of color, manufacturers can choose high-quality coating materials, while also paying attention to selecting appropriate pigment ratios and conducting necessary color matching processes.

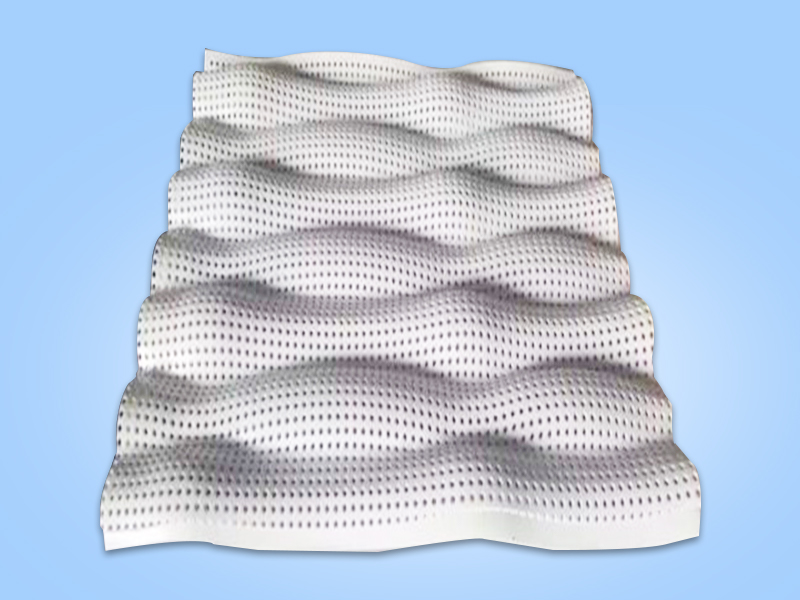

3、 Dimensional accuracy

Aluminum veneer has a wide range of applications in the building decoration industry, so controlling the dimensional accuracy is very important in the customization process.

Firstly, during the processing, minimize waste as much as possible. Due to the high price of aluminum veneer, it is necessary to accurately measure and develop corresponding processing plans before processing to avoid waste. In addition, strict dimensional verification is required after processing, and any deviations should be adjusted in a timely manner.

Secondly, it is necessary to predict the deformation of aluminum veneer as accurately as possible during the design phase. According to the principles of material mechanics, aluminum veneer is prone to deformation such as bending and twisting, so its deformation coefficient needs to be determined through calculation before processing, and adjusted according to the actual situation.

Finally, it is important to pay attention to the splicing between veneers of different sizes. In order to ensure the overall effect, sufficient effort needs to be put into controlling the dimensional accuracy, so that the joints are flat and seamless, and the aesthetics are higher.

4、 Installation details

The installation details of aluminum veneer are also very important. Any negligence can lead to safety hazards or affect the overall effect of the building.

Firstly, there are requirements for the external wall structure. The structure of the exterior wall should have sufficient load-bearing capacity and stability. When selecting installation points, specifications should be followed to ensure that the exterior wall does not experience deformation caused by aluminum material stretching.

Next is the control of quality. During the installation process, each aluminum veneer needs to be strictly inspected. If there are any damages, deformations, or other issues, they should be replaced in a timely manner. In addition, it is important to note that the exterior walls attached to the aluminum material must be cleaned thoroughly to ensure the stability of the installation.

Finally, it is important to pay attention to safety issues. During installation, professional installation tools and safety equipment should be equipped to ensure the personal safety of construction personnel. At the same time, after installation, the installation quality should also be checked to ensure the stability of the aluminum veneer.

5、 Summary

Details determine quality, and aluminum veneer, as a high-end building decoration material, requires attention to detail processing during customized processing. This article provides a detailed explanation from four aspects: color matching, surface treatment, dimensional accuracy, and installation details. In practical applications, only by paying attention to details and continuously optimizing and improving can the excellent quality of aluminum veneer be demonstrated.

Customer service QQ

Customer service QQ