Industry information

Company News

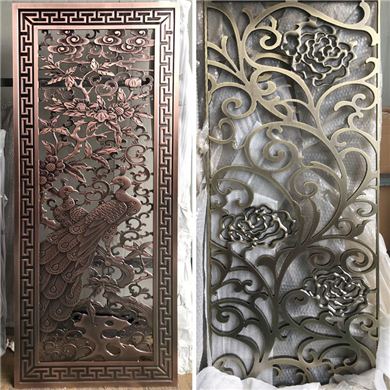

- Punched aluminum veneer: the finishing touch of architectural art

- Fluorocarbon aluminum veneer: the new darling of architectural aesthetics

- Exploring punched aluminum veneer: the fashionable style of aluminum newcomers

- Aluminum veneer, the "fashionable coat" of modern architecture

- Carved aluminum veneer: the unique charm of modern architecture

Industry dynamics

- Carved aluminum veneer, the new aesthetic favorite of modern architecture

- Aluminum veneer: the "fashionable choice" in modern architecture

- Carved aluminum veneer, a fashionable choice for modern architecture

- Optimization of Aluminum Veneer Customization Process

- Aluminum veneer customization, creating a new trend of personalized space

Frequently asked questions

- How to use and maintain aluminum veneer reasonably?

- How to determine the quantity and size of customized aluminum veneer?

- How to solve the environmental problems in the production process of aluminum veneer?

- How to distinguish the quality of aluminum veneer?

- How to use aluminum veneer for innovative design?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Lightweight material of hyperbolic aluminum veneer

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: 2022-03-04 18:10:26

- Click:0

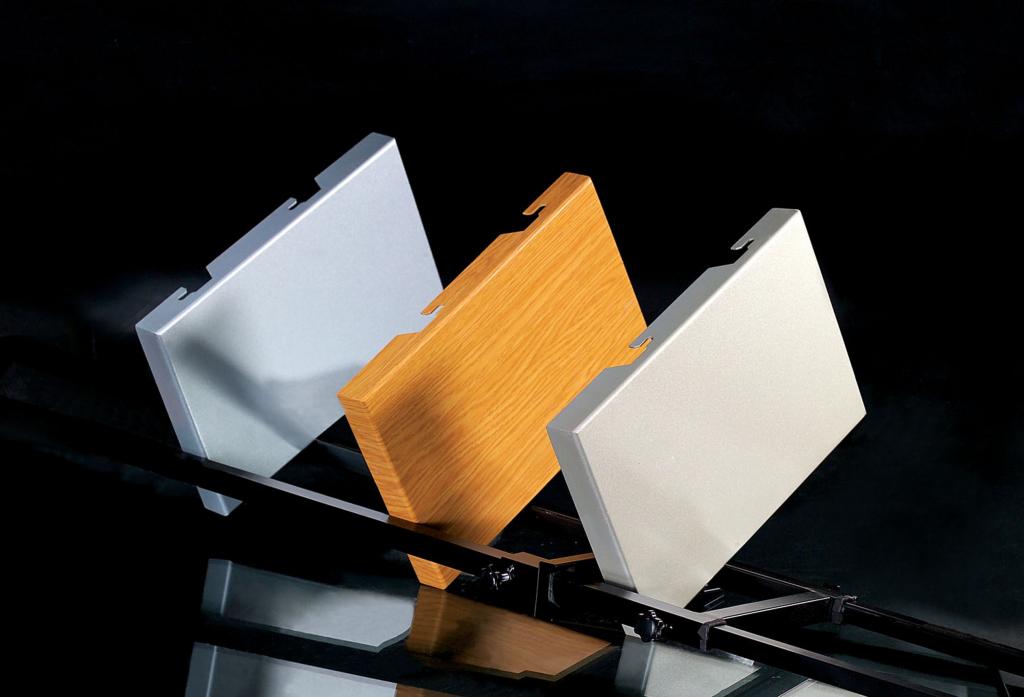

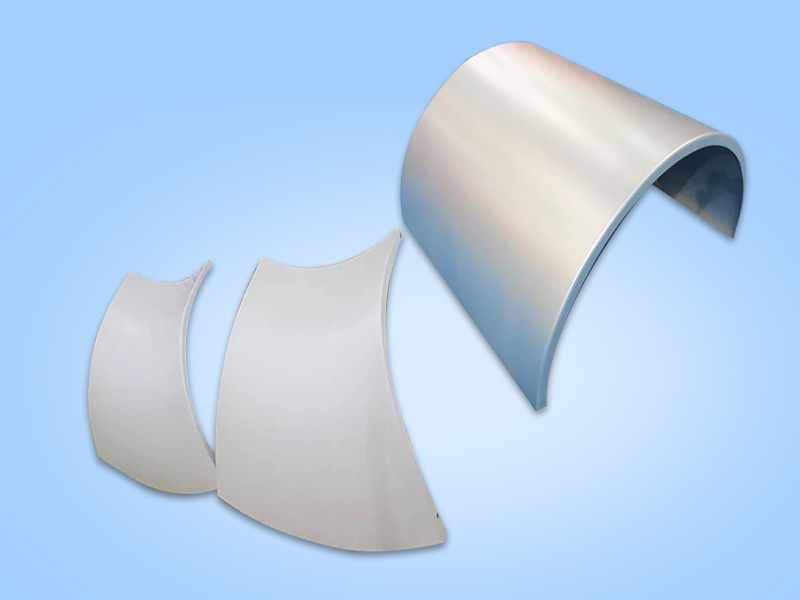

hyperbolicAluminum veneerAs a new type of building material, it has the advantages of being lightweight, durable, and aesthetically pleasing. One of the important reasons for its popularity is its lightweight material. Below is a detailed introduction to the lightweight material of hyperbolic aluminum veneer.

1、 Material characteristics

Hyperbolic aluminum veneer is usually made of high-strength, wear-resistant, and corrosion-resistant metal materials, such as aluminum alloy materials. Compared to traditional building materials, hyperbolic aluminum veneer has lighter weight and higher strength, which can greatly reduce the self weight and structural cost of buildings. Hyperbolic aluminum veneer also has good plasticity and processability, and can be processed and manufactured in various shapes and sizes according to needs.

2、 Production process

The lightweight material of hyperbolic aluminum veneer is closely related to its production process. By adopting advanced production processes and technological means, hyperbolic aluminum veneer can achieve higher strength and better processing performance. For example, aluminum alloy materials can be processed and formed through processes such as rolling and extrusion to improve their strength and plasticity; A dense and strong protective film can be formed through surface treatment techniques such as anodizing, electrophoretic coating, etc., further improving the corrosion resistance and wear resistance of hyperbolic aluminum veneer.

3、 Application Fields

The lightweight material of hyperbolic aluminum veneer has made it widely used in fields such as architectural decoration, advertising billboards, and vehicle manufacturing. For example, in architectural decoration, hyperbolic aluminum veneer can be applied to walls, roofs, doors, windows and other parts to achieve a lighter and more beautiful decorative effect; In the field of billboards, hyperbolic aluminum veneer can be applied to outdoor billboards, lightboxes, and other equipment to achieve a more lightweight and durable effect; In the field of vehicle manufacturing, hyperbolic aluminum veneer can be applied to parts such as the body and doors, achieving a lighter and more environmentally friendly effect.

4、 Conclusion and Suggestions

The lightweight material of hyperbolic aluminum veneer can achieve a more lightweight, beautiful, and environmentally friendly architectural decoration effect. For designers, they can choose suppliers of high-quality and stable hyperbolic aluminum veneer products and services by understanding market trends and comparing products and services from different suppliers. We also need to strengthen our awareness of environmental protection and responsibility, and actively promote the application and development of green environmental protection concepts in the construction industry.

Customer service QQ

Customer service QQ