Industry information

Company News

- Punched aluminum veneer: the fashionable choice in modern architecture?

- Aluminum veneer customization, creating personalized space and new fashion

- Aluminum veneer customization, creating a new trend of personalized space

- Fluorocarbon aluminum veneer: the new aesthetic favorite of modern architecture

- Fluorocarbon aluminum veneer: the fashionable choice for modern architecture?

Industry dynamics

- Aluminum veneer adds fashion and artistic atmosphere to buildings

- The charm of aluminum veneer: it's not just about its appearance

- Aluminum veneer customization: an artistic journey to create personalized spaces

- The simple and atmospheric roller coated aluminum veneer on the exterior wall adds an elegant style to the building

- Aluminum veneer: the "fashionable coat" of modern architecture

Frequently asked questions

- How to improve the fire resistance of aluminum veneer?

- How to use and maintain aluminum veneer reasonably?

- How to improve the insulation performance of aluminum veneer?

- How to solve the environmental problems in the production process of aluminum veneer?

- How to distinguish the quality of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Optimization of Aluminum Veneer Customization Process

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: March 18, 2025 16:52:15

- Click:0

Aluminum veneerCustomization, as a new type of building decoration material, its production process is also one of the important factors affecting its quality and performance. In the actual production process, continuous process optimization is needed to improve production efficiency, reduce costs, and enhance product quality. Below, we will provide a detailed introduction to the optimization of aluminum veneer customization process.

1、 Optimize production process flow

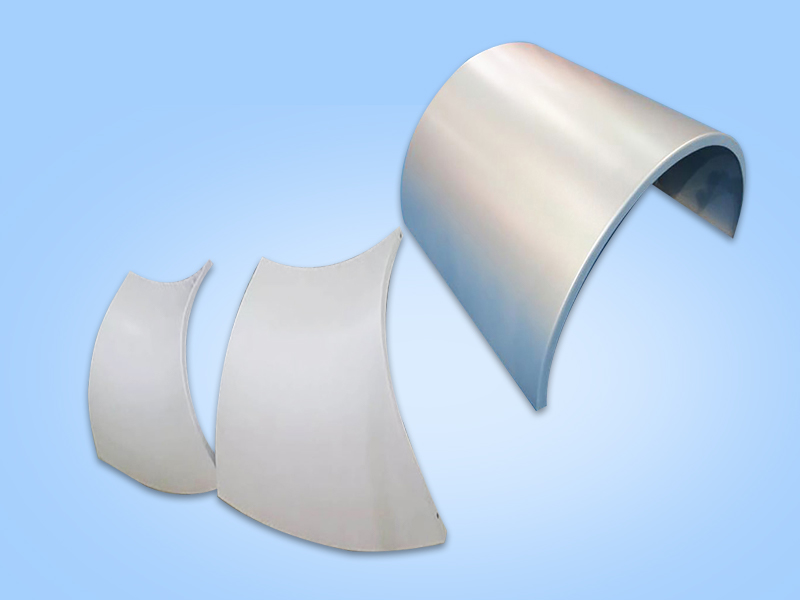

The production process of customized aluminum veneer is an important factor affecting its production efficiency and product quality. When conducting process optimization, it is necessary to conduct a comprehensive analysis and evaluation of the production process flow, identify existing problems and bottlenecks, and take corresponding measures for improvement. For example, advanced automation equipment and technology can be adopted to improve production efficiency and product quality; It can optimize the production process, reduce intermediate links and scrap rates, and lower costs.

2、 Optimize the selection and use of raw materials

The selection and use of raw materials are also important factors affecting the quality of customized aluminum veneer products. When optimizing the process, it is necessary to comprehensively evaluate and analyze the types, quality, and prices of raw materials, and select high-quality raw materials as production materials. It is also necessary to use raw materials reasonably, avoid waste and loss, and improve resource utilization.

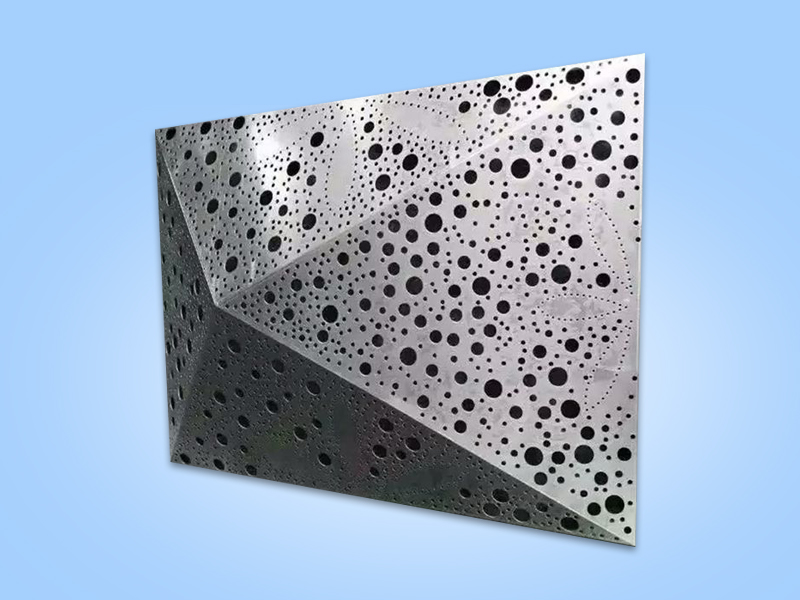

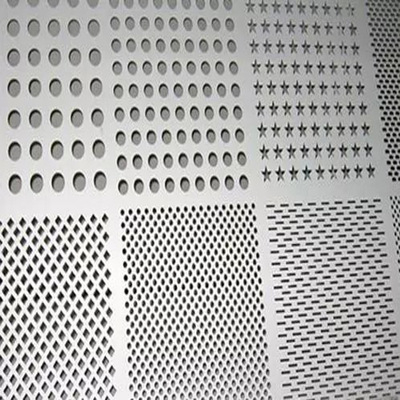

3、 Optimize surface treatment technology

The surface treatment technology of aluminum veneer is also an important factor affecting its decorative effect and durability. When optimizing the process, it is necessary to comprehensively evaluate and analyze different surface treatment technologies, and select suitable treatment methods and materials. For example, advanced spraying technology and equipment can be used to improve the uniformity and adhesion of the coating; It can optimize the anodizing process to improve the corrosion resistance and wear resistance of the product.

4、 Optimize equipment maintenance and management

The maintenance and management of equipment is also an important factor affecting the production efficiency and product quality of customized aluminum veneer. When optimizing the process, it is necessary to conduct comprehensive maintenance and management of the equipment to ensure its normal operation and stability. For example, regular equipment maintenance and upkeep can be carried out, and damaged parts can be replaced in a timely manner; A comprehensive equipment management system can be established to improve equipment utilization and management efficiency.

5、 Optimize personnel training and management

Personnel training and management are also important factors affecting the production efficiency and product quality of customized aluminum veneer. When optimizing the process, it is necessary to provide comprehensive training and management to employees to improve their technical level and work quality. For example, regular technical training and exchange activities can be organized to enhance employees' professional skills and innovation abilities; A comprehensive personnel management system can be established to stimulate employees' work enthusiasm and creativity.

The process optimization of customized aluminum veneer is a very important part. In the actual operation process, it is necessary to carry out reasonable process optimization according to the actual situation to improve production efficiency, reduce costs, and enhance product quality. We also need to consider future development trends and environmental protection and energy conservation issues, actively respond to national policies and industry standards, and promote the healthy development of the aluminum veneer customization industry.

Customer service QQ

Customer service QQ