Industry information

Company News

- Aluminum veneer customization, creating a new trend of personalized space

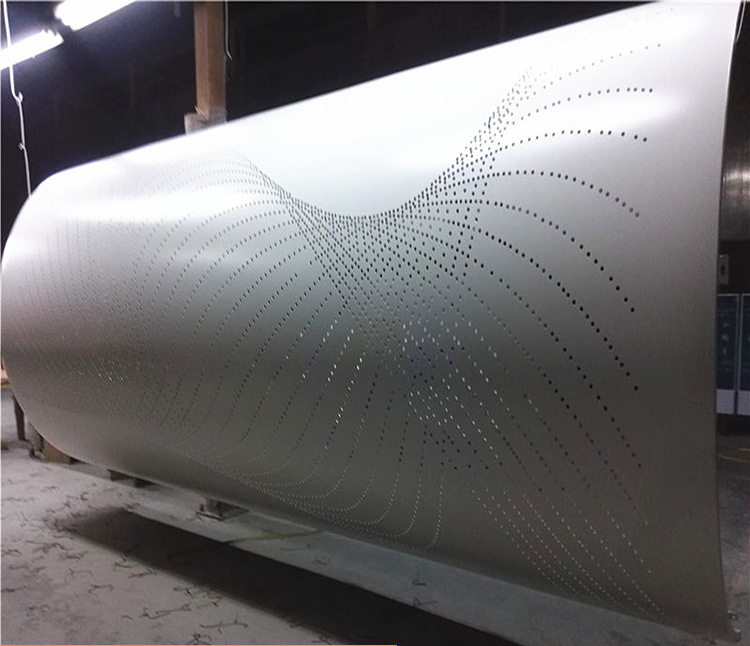

- Punched aluminum veneer: the fashionable choice for modern architecture?

- Fluorocarbon aluminum veneer: the fashionable "coat" of modern architecture

- Carved aluminum veneer: the unique charm of modern architecture

- Fluorocarbon aluminum veneer: the 'invisible guardian' of modern architecture

Industry dynamics

- Unlimited creativity, 2.0mm aluminum veneer creates unique decorative effects

- Will the use of aluminum veneer affect the environmental performance of buildings?

- Control and management of customized construction process for aluminum veneer

- Carved aluminum veneer, a unique style of aluminum art

- Innovative application of hyperbolic aluminum veneer in outdoor decoration

Frequently asked questions

- How to improve the insulation performance of aluminum veneer?

- How to solve the environmental problems in the production process of aluminum veneer?

- How to distinguish the quality of aluminum veneer?

- How to design customized aluminum veneer?

- How to improve the fire resistance of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Quality assurance for customized aluminum veneer: strict quality standards to create excellent quality

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: 2022-02-22 22:53:59

- Click:0

Aluminum veneerCustomized quality assurance: strict quality standards, creating excellent quality

In the field of modern architecture, aluminum veneer has become a highly favored material. Its lightweight, sturdy, durable, and aesthetically pleasing appearance makes it the preferred choice for architects. However, in order to ensure excellent quality during the customization process of aluminum veneer, strict quality standards and guarantees are required. This article will elaborate on the quality assurance of customized aluminum veneer from the following four aspects.

1、 Strict product inspection standards

The quality assurance of customized aluminum veneer should first pay attention to the product inspection standards. Product inspection standards are an essential step in the production process of aluminum veneer. From the moment raw materials enter the factory, they must be inspected to ensure that there are no defects or damages. During the production process, every processing step must be strictly inspected, including aluminum plate cutting, punching, bending, etc., to ensure that each step meets the design requirements. At the end, a final inspection of the finished product is also required to ensure that each aluminum veneer meets quality standards and customer requirements.

In addition, product inspection standards also include tracking and testing of surface quality, thickness, hardness, bending performance, and other indicators of aluminum veneer. Only by controlling every link and ensuring that every aluminum veneer meets quality standards can we guarantee the excellent quality of the final product.

2、 High quality material selection

The high quality of customized aluminum veneer cannot be achieved without high-quality materials. Choosing high-quality raw materials can improve the stability and durability of aluminum veneer, and also effectively reduce the defect rate during the production process. Therefore, in the process of customizing aluminum veneer, it is crucial to choose high-quality materials such as aluminum, coatings, adhesives, etc.

Firstly, the quality of aluminum must be reliable. Choosing high-quality aluminum materials can effectively avoid problems such as rusting or deformation of aluminum veneers during use. Secondly, when choosing coatings, multiple factors need to be considered, such as weather resistance, appearance, environmental friendliness, and so on. Finally, using high-quality adhesive can also increase the adhesion and durability of aluminum veneer.

3、 Scientific production and processing flow

The production technology of aluminum veneer is constantly upgrading, but as a customized product, the production process always needs to be adjusted according to customer needs. In this process, scientific production and processing procedures become particularly important.

Firstly, implement standardized production and establish standardized operating procedures and processes. To ensure that every step is strictly carried out according to the prescribed procedures, and to fully carry out training and acceptance processes. Secondly, during the processing, it is necessary to pay attention to effective detail control. For example, the settings, operating speed, and tool quality of the machine should be precisely controlled and selected to ensure the efficiency and accuracy of the machining process.

4、 Comprehensive after-sales service

A high-quality aluminum veneer customization company not only produces high-quality aluminum veneer products, but also needs to provide customers with comprehensive after-sales service. Aluminum veneer may inevitably be damaged or require replacement during use. In this situation, customers need to receive timely, efficient, and thoughtful after-sales service.

Therefore, in order to ensure the quality of after-sales service, customization companies need to equip professional after-sales personnel. For the problems that customers encounter during the use of aluminum veneer, after-sales personnel need to respond promptly, solve them quickly, and maintain communication with customers.

5、 Summary

Aluminum veneer is a multifunctional, high-quality, and durable material with a wide range of applications. However, due to the need to pay attention to many details in the production and customization of aluminum veneer, while ensuring quality, we also need to continuously upgrade our technological level and management experience to provide customers with high-quality aluminum veneer products.

Customer service QQ

Customer service QQ