Industry information

Company News

- New rising star in aluminum veneer reveals the unique charm of punched aluminum veneer!

- Fluorocarbon aluminum veneer: the fashion darling of the aluminum industry

- The world of "holes" in aluminum veneer, the charming journey of punching art

- Customized stylish aluminum veneer, interpreting unique spatial aesthetics

- Customized aluminum veneer, creating personalized space and new fashion

Industry dynamics

- Aluminum veneer customization, creating personalized space and new fashion

- Environmental Protection and Sustainable Development of Aluminum Veneer

- Punched aluminum veneer, creating a fashionable new style of architecture!

- Strength and weather resistance testing of aluminum veneer

- Introduction to the advantages and functions of stone patterned aluminum veneer for curtain walls

Frequently asked questions

- How to distinguish the quality of aluminum veneer?

- How to solve the environmental problems in the production process of aluminum veneer?

- How to use aluminum veneer for innovative design?

- How to improve the insulation performance of aluminum veneer?

- How to improve the fire resistance of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

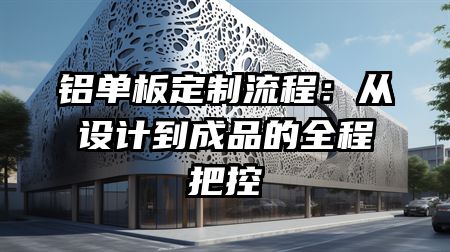

Aluminum veneer customization process: full control from design to finished product

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: February 23, 2025 19:59:03

- Click:0

Aluminum veneerCustomization process: full control from design to finished product

Aluminum veneer is a high-end building decoration material that is highly favored due to its lightweight, corrosion resistance, heat resistance, fire resistance, and other characteristics. In the field of architectural decoration, aluminum veneer is widely used in indoor and outdoor walls, ceilings, curtain walls, commercial display stands, decoration partitions, and other aspects. Aluminum veneer customization is an important part of aluminum veneer application. This article will provide a detailed explanation of the aluminum veneer customization process from four aspects: design, material procurement, production, and finished product delivery.

1、 Design

The first step in customizing aluminum veneer is the design of the product. Based on the client's needs and the designer's creativity, the designer can use CAD (computer-aided design) software or hand drawn design paper to create design drawings. The design drawing needs to include important information such as product size, color, and pattern. In the design process, designers need to follow the principles of safety, aesthetics, practicality, time-saving, and labor-saving.

After the design is completed, it needs to be presented and confirmed to the client. If the customer approves of the design drawings, a contract needs to be signed, a deposit needs to be paid, and subsequent material procurement work needs to be carried out.

2、 Material procurement

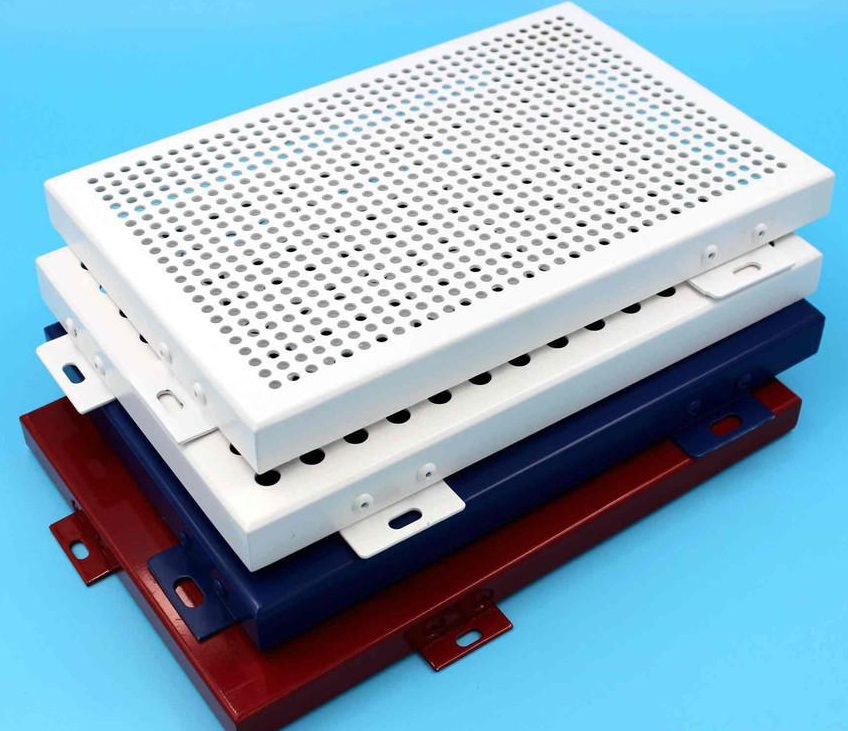

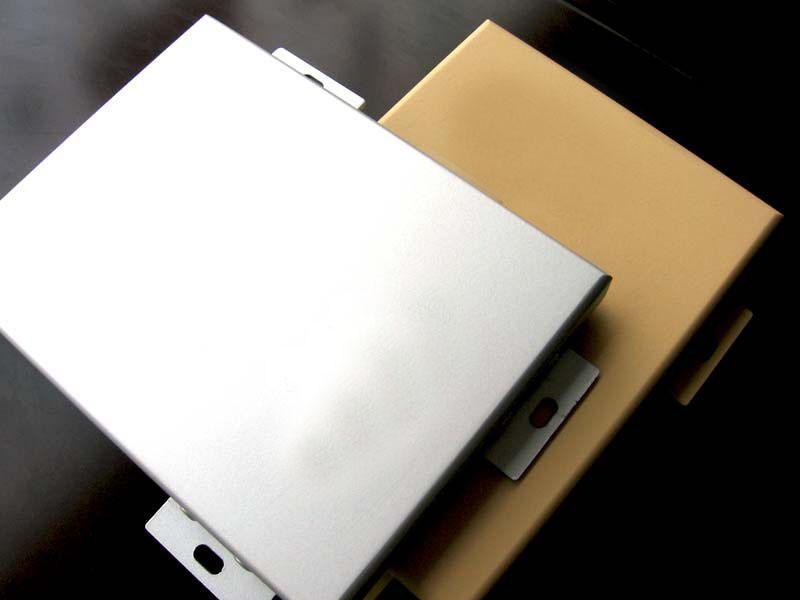

The quality and appearance of the finished product largely depend on the materials selected. The main materials of aluminum veneer products include aluminum veneer, coatings, screws, etc.

Firstly, it is necessary to choose high-quality aluminum alloy sheets, whose thickness should comply with national standards. Specifically, if it is aluminum veneer used outdoors, it is necessary to choose materials with good corrosion resistance. In addition, the coating is an important protective layer on the surface of aluminum veneer, and it also affects the aesthetic and protective effects of the finished product. Therefore, the coating needs to comply with international standards and have characteristics such as UV resistance, pollution resistance, and fading resistance. Finally, it is necessary to purchase screws and other connectors that meet the requirements.

It is worth noting that strict testing and evaluation of materials are required during the procurement process to ensure that their quality and performance meet the requirements. This step is also a crucial step in the aluminum veneer customization process.

3、 Production

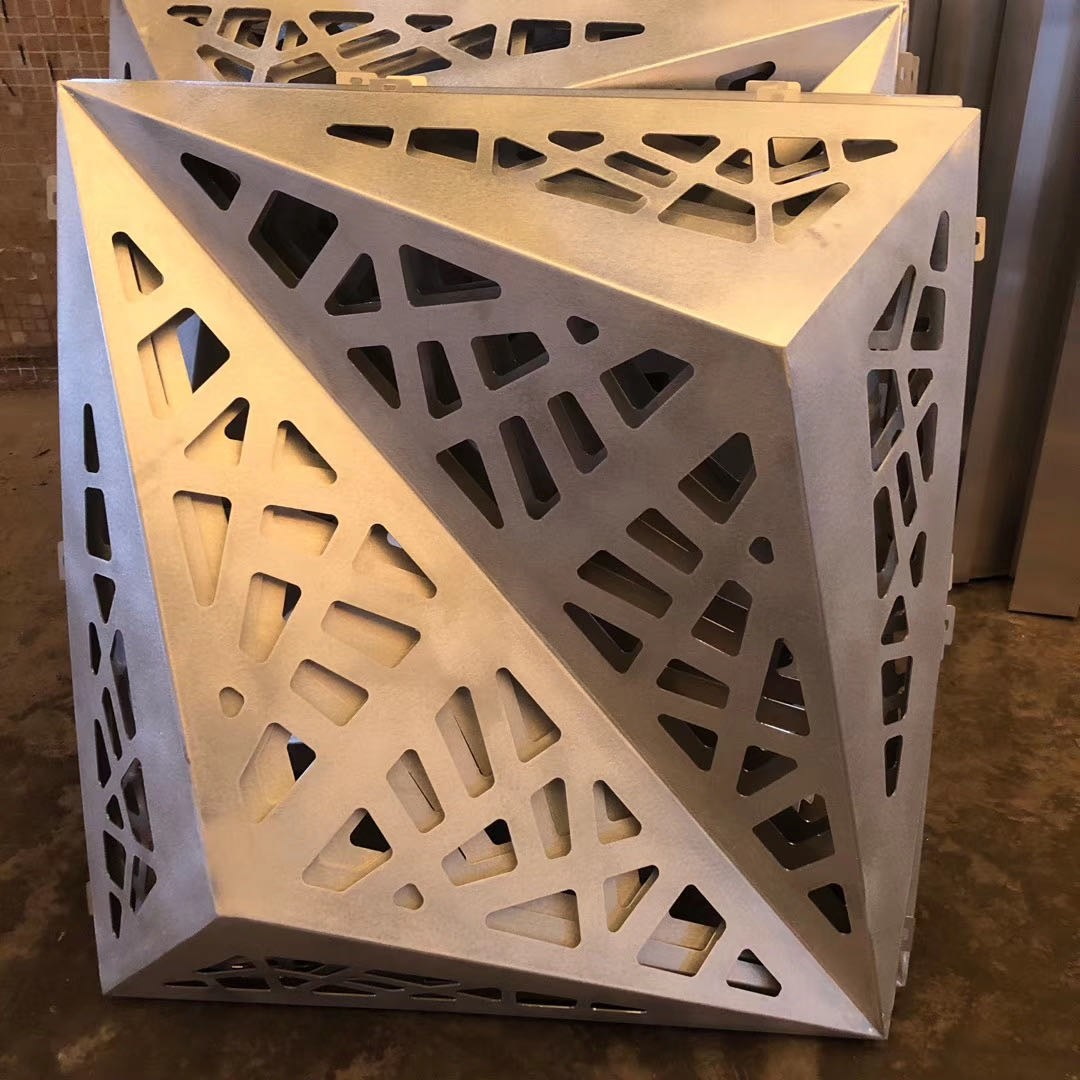

The production process is the most important stage in the customization of aluminum veneer. The production of aluminum veneer requires multiple processes such as cutting, bending, drilling, spraying, and assembly.

Firstly, the purchased aluminum veneer needs to be processed according to the design requirements, which requires the use of CNC machining equipment to ensure the accuracy and consistency of dimensions. Then, according to the requirements of the design drawings, the aluminum veneer can be processed through bending, drilling, and other methods, as well as drilling, cutting, and other treatments. Next, the coating application process requires the use of a spraying machine, which aims to cover the surface of the aluminum veneer with a high-quality coating to improve its appearance and enhance its anti-corrosion performance. Finally, according to the design requirements, assemble the aluminum veneer panels and connecting components such as screws.

After production is completed, inspection is also required to ensure that the finished product meets the design requirements and customer needs. If it is necessary to add relevant logos, trademarks, or other secondary processing content, it can also be completed at this stage.

4、 Finished product delivery

After the finished product inspection is completed, logistics personnel need to be arranged to deliver the finished product to the customer's designated location. During the shipping process, it is necessary to strictly package and moisture-proof the products. After arriving at the customer's site, it is necessary to unpack and install the goods.

During the installation process, it is necessary to follow the principles of safety production and install according to the requirements of the design drawings. At the same time, it is necessary to ensure that the contact area of each connection point is sufficient, the screws are tightened firmly, and special attention is paid to the safety of the workers during the entire installation process.

5、 Summary:

The process of customizing aluminum veneer involves multiple steps such as design, material procurement, production, and finished product delivery. From the above analysis, it can be seen that each link is very important. Only by strictly controlling each link can high-quality aluminum veneer products be produced. Aluminum veneer customization has the advantages of large development space and wide applicability, and will also be more widely used in the field of architectural decoration in the future.

Customer service QQ

Customer service QQ