Industry information

Company News

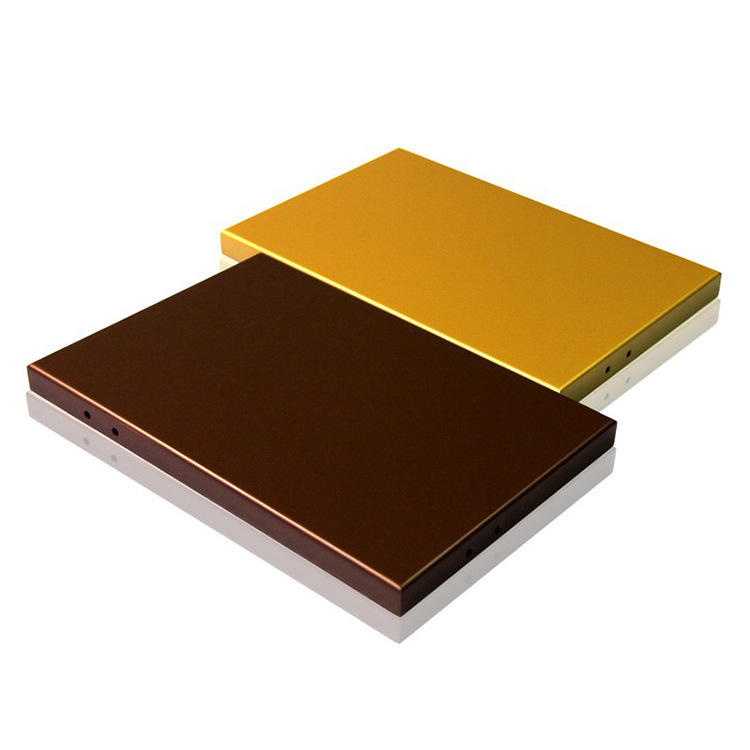

- Fluorocarbon aluminum veneer: the hidden champion of fashionable architecture

- Aluminum veneer: the fashionable choice for modern architecture

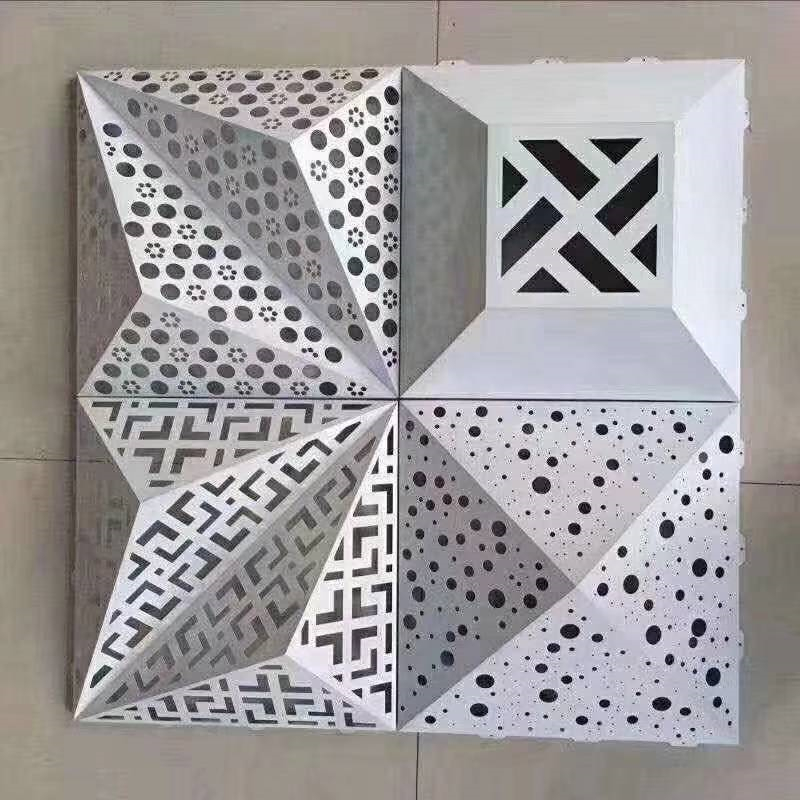

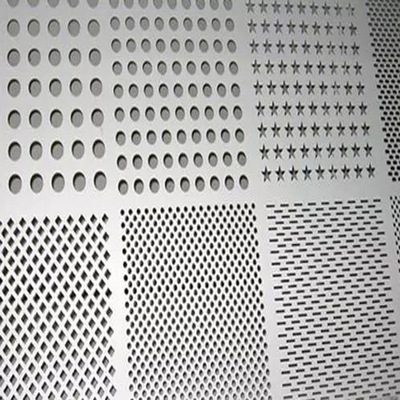

- Unlimited creativity, perforated aluminum veneer takes you into the world of art

- Exploring perforated aluminum veneer: a mysterious veil in modern architecture

- Fluorocarbon aluminum veneer: a perfect embodiment of the integration of architectural aesthetics and technology

Industry dynamics

- Unlimited creativity, 2.0mm aluminum veneer creates unique decorative effects

- Aluminum Veneer: Unveiling the 'Invisible Iron Man' in Modern Architecture

- Analysis of the application value of 3mm perforated aluminum veneer, a new favorite in the furniture industry

- Construction precautions for 3mm aluminum veneer

- Selection and application of customized design scheme for aluminum veneer

Frequently asked questions

- How to solve the environmental problems in the production process of aluminum veneer?

- How to improve the insulation performance of aluminum veneer?

- How to design customized aluminum veneer?

- How to improve the fire resistance of aluminum veneer?

- How to distinguish the quality of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Embossing process of 2.5mm aluminum veneer

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: March 15, 2025 23:53:41

- Click:0

With the development of the architectural decoration industry, the thickness of 2.5mmAluminum veneerThe application is becoming increasingly widespread. In addition to conventional surface treatment methods, embossing has also become one of the commonly used surface treatment methods. The embossing process of 2.5mm thick aluminum veneer will be detailed below.

1、 Principle of embossing process

Embossing process is a technique that uses pressure to form certain patterns on the surface of aluminum veneer. In the embossing process of 2.5mm thick aluminum veneer, it is necessary to first prepare a template with patterns, and then place the template on the aluminum veneer to be processed. The desired patterns are formed on the surface of the substrate by pressure, and finally the desired decorative effect is achieved.

2、 Embossing process flow

1. Prepare templates: Design and produce as needed to ensure the clarity and accuracy of the patterns.

2. Cleaning the substrate: Use appropriate cleaning agents to clean the substrate to remove surface dirt and grease.

3. Template installation: Install the prepared template onto the substrate, ensuring that the position and orientation are correct.

4. Apply pressure: Use professional mechanical equipment or hand tools to apply pressure to the substrate to shape the pattern.

5. Follow up processing: Perform subsequent processing as needed, such as polishing, drying, etc., to enhance the decorative effect.

3、 Precautions

When performing the embossing process on 2.5mm thick aluminum veneer, the following points should be noted:

1. It is necessary to choose and match according to actual needs and usage environment to ensure that the decorative effect meets the expected requirements.

2. When selecting materials and processing, attention should be paid to the matching of quality and specifications to avoid situations where problems cannot be solved.

3. During the construction process, it is necessary to pay attention to the implementation of safety protection measures to prevent accidental injury accidents.

4、 Summary

The embossing process of 2.5mm thick aluminum veneer is one of the important factors affecting its application effect. During the embossing process, it is necessary to pay attention to the preparation work, correct selection and matching of materials, and strict quality inspection to ensure that the product meets the expected requirements. At the same time, it can also be reasonably matched and used according to market demand and aesthetic standards to enhance the beauty and added value of the product.

Customer service QQ

Customer service QQ