Industry information

Company News

- Fluorocarbon aluminum veneer: a new favorite in architecture and a pioneer in environmental protection!

- The charm of carved aluminum veneer, the new darling of architectural art

- Customized aluminum veneer to create your own unique aesthetic space

- Fluorocarbon aluminum veneer: the new darling of the aluminum industry, a new choice for home decoration!

- Fluorocarbon aluminum veneer: a new favorite in architecture and a new trend in environmental protection

Industry dynamics

- Fluorocarbon aluminum veneer: the new darling of the aluminum industry, perfectly combining appearance and durability!

- Ancient charm and modern style, carved aluminum veneer interprets a new chapter in art

- Exploring punched aluminum veneer: the charm of industrial aesthetics

- Exploring fluorocarbon aluminum veneer: the new darling of the construction industry!

- Aluminum veneer: the "fashionable choice" in modern architecture

Frequently asked questions

- How to store and transport aluminum veneer?

- How to improve the insulation performance of aluminum veneer?

- How to use aluminum veneer for innovative design?

- How to improve the fire resistance of aluminum veneer?

- How to determine the quantity and size of customized aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

How to verify the lightning protection performance of punched aluminum veneer?

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: 2022-03-17 04:19:22

- Click:0

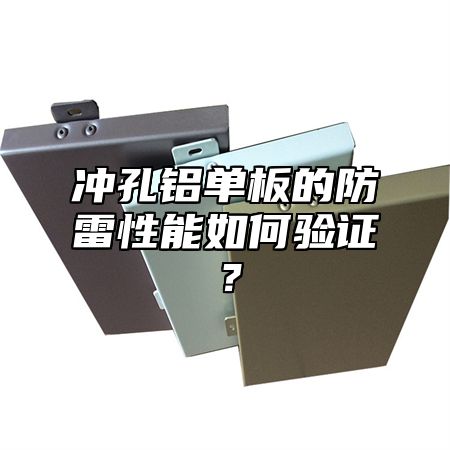

punchingAluminum veneerAs a widely used material in the fields of architectural decoration, advertising billboards, curtain walls, etc., its lightning protection performance is also an important aspect. The lightning protection performance can affect the effectiveness and safety of perforated aluminum veneer. The following will introduce how to verify the lightning protection performance of punched aluminum veneer from the following aspects.

1. Determine the testing method

Firstly, it is necessary to determine the lightning protection performance testing method for punched aluminum veneer according to the actual situation. The commonly used testing methods currently include lightning wave simulation test, potential difference test, etc. In practical operation, it is necessary to select appropriate testing methods for evaluation based on different application scenarios and requirements.

1. Prepare testing equipment

Before conducting lightning protection performance testing, it is necessary to prepare the corresponding testing equipment. Common testing equipment includes lightning wave simulators, potentiometers, etc. When preparing testing equipment, attention should be paid to factors such as equipment specifications, models, and stability to ensure the accuracy and reliability of its test results.

1. Conduct testing experiments

When conducting lightning protection performance testing, it is necessary to operate according to the preset test parameters and conditions. Specifically, testing can be conducted in the following ways:

(1) Conduct simulation tests on punched aluminum veneer using a flashing wave simulator to observe whether breakdown occurs;

(2) Place the punched aluminum veneer on a potential difference meter for potential difference testing and observe whether there is a sudden voltage change phenomenon;

(3) Set other relevant testing parameters and conditions according to the actual situation.

How to improve the lightning protection performance of punched aluminum veneer?

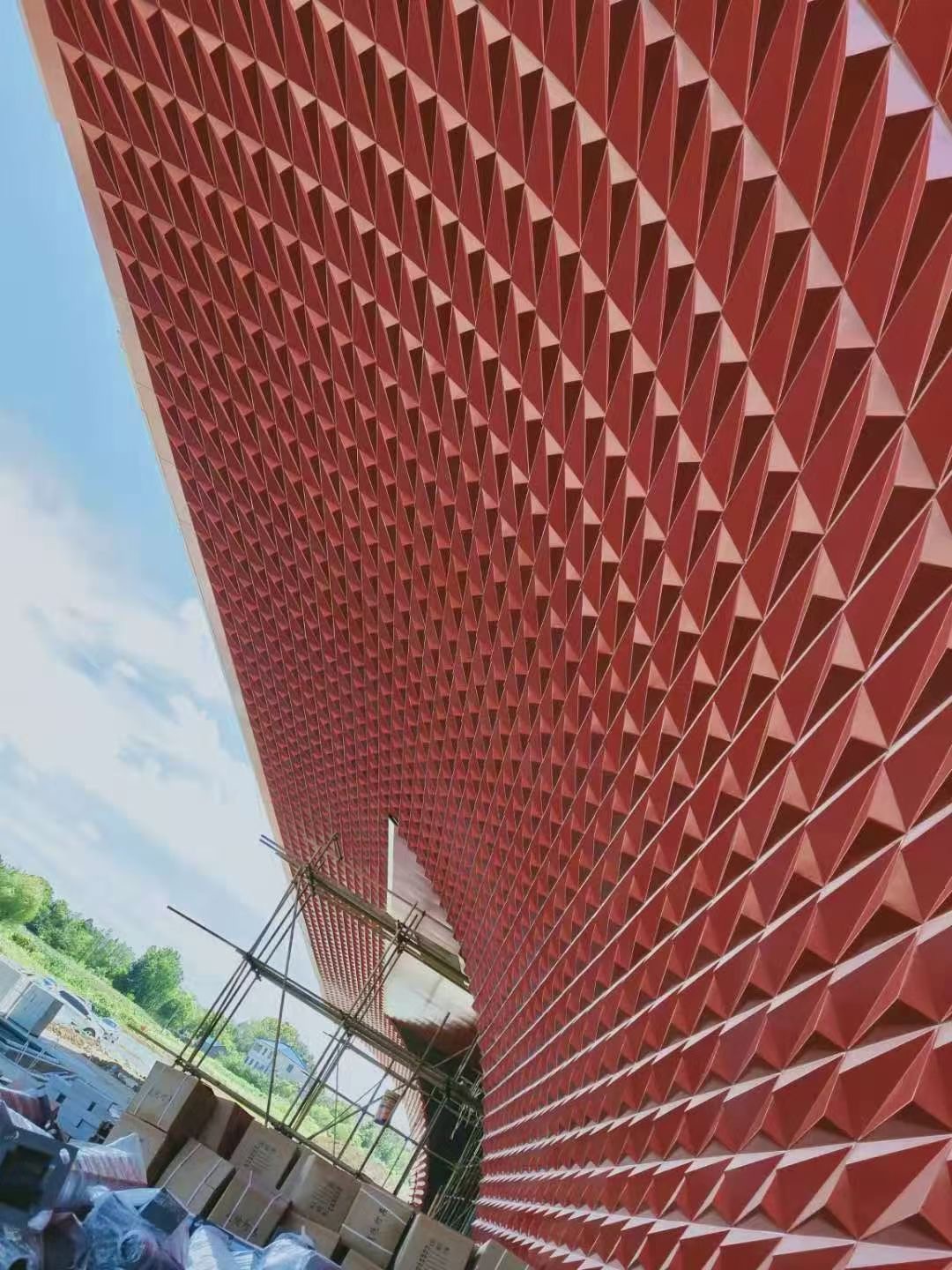

In order to improve the lightning protection performance of punched aluminum veneer, the following measures can be taken:

(1) Select materials and coatings with good lightning protection performance;

(2) Strengthen surface treatment processes to improve their compressive, tensile, and impact resistance properties;

(3) Adopt lightning protection measures, such as setting up lightning rods, installing lightning protection belts, etc;

(4) Regularly inspect and maintain the surface condition and structural integrity of punched aluminum veneer, and promptly address any potential problems and malfunctions.

Customer service QQ

Customer service QQ