Industry information

Company News

- Exploring Fluorocarbon Aluminum Veneer: A New Favorite in Modern Architectural Aesthetics

- Lightweight and fashionable, perforated aluminum veneer has infinite charm

- Carved Aluminum Veneer: Aluminum Art, Creating Unique Space Beauty

- Punched aluminum veneer: the new darling of architectural aesthetics, revealing its unique charm!

- Aluminum veneer customization, creating a new trend of personalized space

Industry dynamics

- Aluminum veneer: the invisible magician of the construction industry

- Ancient charm and modern style, carved aluminum veneer interprets modern aesthetics

- Application of 1.5mm aluminum veneer ceiling in the field of construction

- Lightweight material of hyperbolic aluminum veneer

- Curved surface and bending forming of curtain wall aluminum veneer

Frequently asked questions

- How to use aluminum veneer for innovative design?

- How to improve the insulation performance of aluminum veneer?

- How to store and transport aluminum veneer?

- How to solve the environmental problems in the production process of aluminum veneer?

- How to use and maintain aluminum veneer reasonably?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

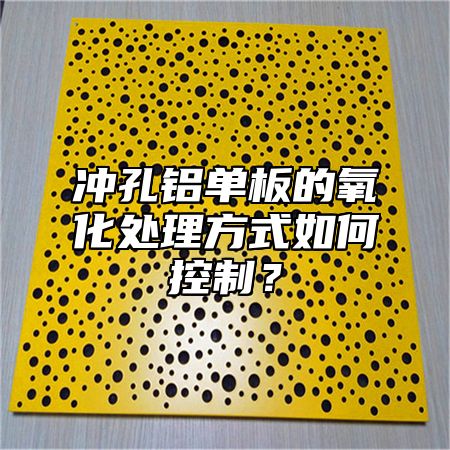

How to control the oxidation treatment method of punched aluminum veneer?

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: 2022-03-15 18:19:47

- Click:0

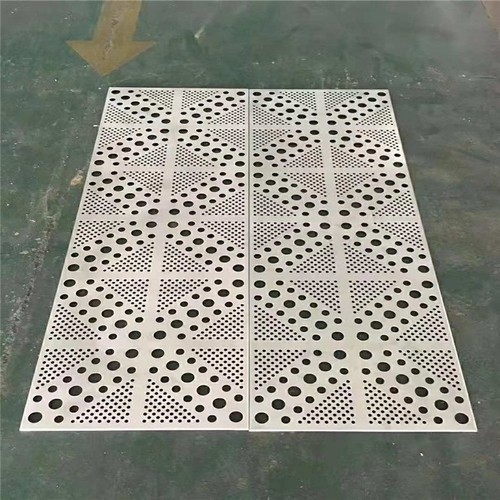

punchingAluminum veneerAs a material widely used in fields such as architectural decoration, billboards, curtain walls, etc., its surface treatment process is also an important aspect. Oxidation treatment is a commonly used surface treatment process that can form a dense and uniform oxide film or coating, thereby improving its tensile strength and hardness. In order to ensure that the oxidation treatment quality of punched aluminum veneer meets the requirements, a series of measures need to be taken to control it. The following will introduce how to control the oxidation treatment of punched aluminum veneer from the following aspects.

1. Determine the oxidation treatment parameters

Firstly, it is necessary to determine the oxidation treatment parameters for punched aluminum veneer according to the actual situation. These parameters include oxidation temperature, oxidation time, voltage and current, etc. In practical operation, it is necessary to adjust and optimize according to different factors such as punching aluminum veneer material and thickness to ensure its oxidation effect and quality.

1. Choose the appropriate oxidant

In addition to determining the oxidation treatment parameters, it is also necessary to choose suitable oxidants. The commonly used oxidants currently include sulfuric acid, nitric acid, hydrochloric acid, etc. Among them, sulfuric acid is the most commonly used one. When selecting oxidants, attention should be paid to factors such as concentration, purity, and stability to ensure that their impact on punched aluminum veneers meets the requirements.

1. Strengthen the monitoring of the oxidation treatment process

During the oxidation process, it is necessary to strengthen monitoring and management to ensure its quality and safety. Specifically, monitoring can be carried out through the following methods:

(1) Use instruments such as thermometers and voltmeters to measure parameters such as temperature, voltage, and current during oxidation treatment;

(2) Regularly inspect the quality and thickness parameters of the oxide film, and make necessary adjustments and corrections;

(3) Strengthen on-site management to ensure the safety and standardized operation of construction personnel.

How to improve the oxidation treatment quality of punched aluminum veneer?

In order to improve the oxidation treatment quality of punched aluminum veneer, the following measures can be taken:

(1) Strictly follow the design requirements for operation, ensuring that all parameters meet the standards;

(2) Choose high-quality raw materials and reliable suppliers to ensure the quality and performance of punched aluminum veneer;

(3) Strengthen on-site management to ensure the safety and standardization of the construction process;

(4) Strengthen post maintenance and management, and promptly address potential issues and malfunctions.

Customer service QQ

Customer service QQ