Industry information

Company News

- How much do you know about fluorocarbon aluminum veneer: the new darling of modern architecture?

- Carved aluminum veneer: the finishing touch of modern architecture

- Aluminum veneer: lightweight material, creating a modern and fashionable space!

- Aluminum veneer customization, creating a new trend of personalized space!

- Fluorocarbon aluminum veneer: the new darling of architectural beauty

Industry dynamics

- Fluorocarbon aluminum veneer: a fashionable choice for modern architecture

- Punched aluminum veneer: the "invisible garment" of fashionable architecture

- How to control the oxidation treatment method of punched aluminum veneer?

- Fluorocarbon aluminum veneer: the "fashionable coat" of modern architecture

- Unveiling Punched Aluminum Veneer: A Small Freshness in the Aluminum Industry and a Fashion Favorite in the Decoration Industry

Frequently asked questions

- How to design customized aluminum veneer?

- How to distinguish the quality of aluminum veneer?

- How to use and maintain aluminum veneer reasonably?

- How to store and transport aluminum veneer?

- How to improve the insulation performance of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Aluminum veneer manufacturer's production process publicly disclosed

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: February 28, 2025 11:34:23

- Click:0

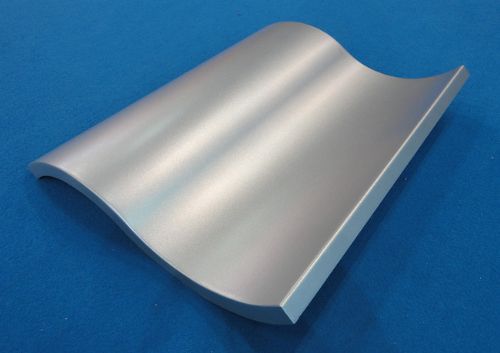

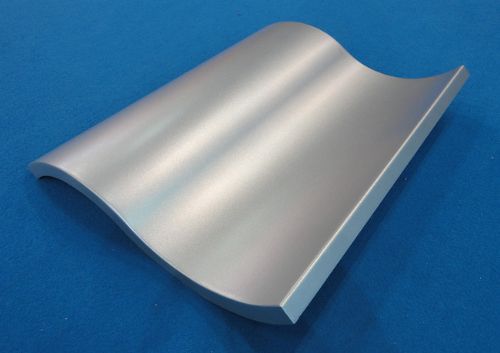

Aluminum veneerAs a building decoration material, its production process is one of the important factors that customers choose. Below is a detailed introduction to the production process of aluminum veneer manufacturers.

1、 Raw material procurement

1. Aluminum: The main raw material for aluminum veneer is aluminum, and high-quality aluminum that meets national standards should be selected.

2. Surface treatment: The surface treatment of aluminum veneer includes spraying, anodizing, powder coating, etc., and surface treatment methods and materials that comply with national standards should be selected.

3. Auxiliary materials: The auxiliary materials for aluminum veneer include keel, sealant, etc., and materials that meet national standards should be selected.

2、 Preparation of processing equipment

1. Cutting equipment: The production of aluminum veneer requires the use of advanced processing equipment, such as CNC cutting machines, laser cutting machines, etc.

2. Welding equipment: The production of aluminum veneer requires the use of welding equipment, such as gas shielded welding machines, spot welding machines, etc.

3. Grinding equipment: The production of aluminum veneer requires the use of grinding equipment, such as grinding machines, polishing machines, etc.

3、 Production and processing

1. Cutting: Customize the size and shape of aluminum veneer according to customer needs.

2. Cutting: Cut the aluminum material according to the predetermined size and shape.

3. Welding: Weld the aluminum material to ensure the strength and stability of the product.

4. Polishing: Polish the welded aluminum veneer to ensure surface quality.

5. Surface treatment: Surface treatment of polished aluminum veneer, such as spraying, anodizing, powder coating, etc.

6. Inspection: Inspect the completed aluminum veneer to ensure that the product quality meets the standard requirements.

4、 Packaging and transportation

1. Packaging: Packaging the completed aluminum veneer to protect the product from damage.

2. Transportation: Aluminum veneers can be transported by sea, land, and other methods to meet customer needs.

5、 After sales service guarantee

1. Warranty period: Aluminum veneer manufacturers should provide a reasonable warranty period for their products to protect the rights and interests of customers.

2. Maintenance: Aluminum veneer manufacturers should provide comprehensive after-sales service to ensure timely repair and maintenance during the use of aluminum veneer.

3. Customer feedback: Aluminum veneer manufacturers should promptly pay attention to customer feedback and solve the problems and needs encountered by customers during use.

The production process of aluminum veneer manufacturers mainly includes raw material procurement, preparation of processing equipment, production and processing, packaging and transportation, and after-sales service guarantee. In the actual operation process, it is necessary to follow relevant norms and standards for operation and management, strengthen communication and collaboration, and improve work efficiency and quality level. We also need to pay attention to issues such as environmental protection and energy conservation, continuously innovate and improve products and services, and meet the needs of customers and the expectations of society.

Customer service QQ

Customer service QQ