Industry information

Company News

- Fluorocarbon aluminum veneer: a new favorite in architecture and a pioneer in environmental protection!

- Fluorocarbon aluminum veneer: the fashionable "coat" of modern architecture

- Fluorocarbon aluminum veneer: the fashionable new favorite in the aluminum industry

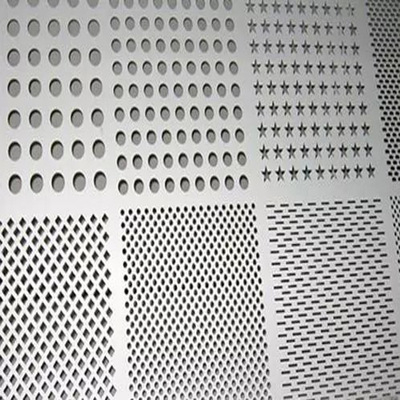

- New rising star in aluminum veneer reveals the unique charm of punched aluminum veneer!

- Aluminum veneer: lightweight building material, shaping the beauty of modern architecture

Industry dynamics

- Aluminum veneer adds fashion and artistic atmosphere to buildings

- Aluminum veneer price - thickness, specifications, and quotation interpretation

- What are the advantages and disadvantages of aluminum veneer compared to stone exterior walls?

- Future development trend of aluminum veneer prices

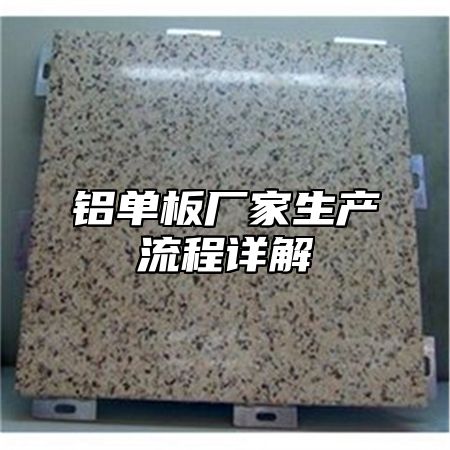

- Detailed explanation of the production process of aluminum veneer manufacturers

Frequently asked questions

- How to design customized aluminum veneer?

- How to solve the environmental problems in the production process of aluminum veneer?

- How to determine the quantity and size of customized aluminum veneer?

- How to identify the quality of aluminum veneer?

- How to use and maintain aluminum veneer reasonably?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Detailed explanation of the production process of aluminum veneer manufacturers

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: February 28, 2025 14:59:12

- Click:0

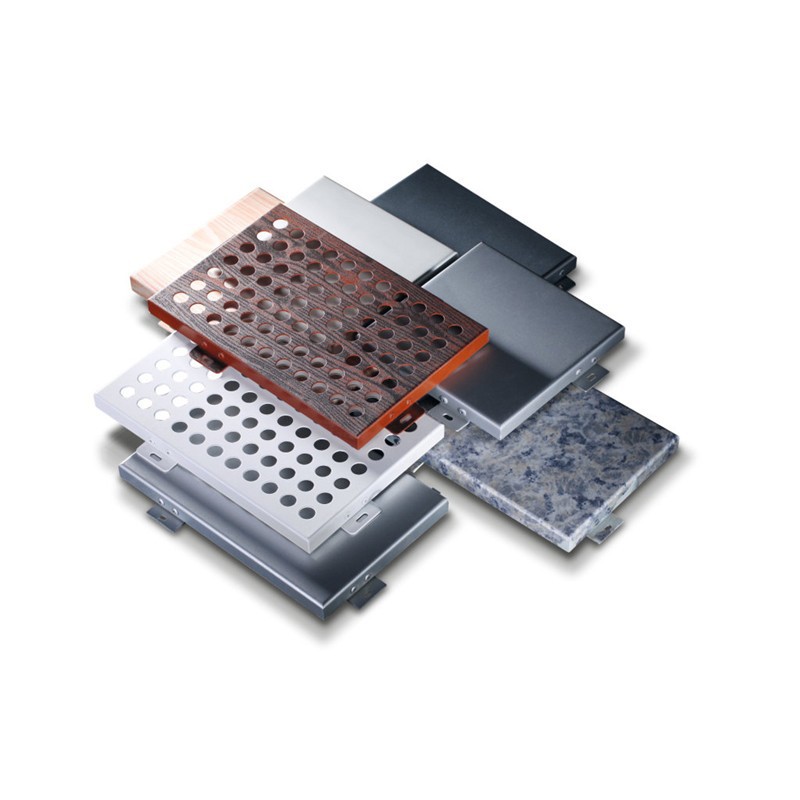

Aluminum veneerAs a building decoration material, its production process is an important link in ensuring product quality and performance. Below, we will provide a detailed introduction to the production process of aluminum veneer manufacturers.

1、 Raw material procurement and preparation

1. Aluminum procurement: Purchase aluminum materials that meet standards from legitimate channels to ensure the quality and performance of aluminum veneers.

2. Surface treatment: Surface treatment of aluminum materials, including spraying, anodizing, powder coating, etc., to improve the decorative effect and corrosion resistance of aluminum veneers.

3. Procurement of auxiliary materials: Purchase corresponding auxiliary materials as needed, such as keel, sealant, etc.

2、 Processing and Forming

1. Cutting and Drilling: Cut and drill aluminum materials according to design requirements to meet specific building structures and decorative needs.

2. Bending and welding: Bending and welding aluminum materials to form specific building structures and decorative effects.

3. Sheet metal processing: Sheet metal processing is performed on aluminum materials to form the basic shape and size of aluminum veneers.

3、 Surface treatment

1. Spraying: Spraying treatment is applied to aluminum veneer to improve its decorative effect and corrosion resistance.

2. Anodizing: Anodizing treatment is applied to aluminum veneer to enhance its decorative effect and corrosion resistance.

3. Powder coating: Powder coating treatment is applied to aluminum veneer to improve its decorative effect and corrosion resistance.

4、 Quality inspection

1. Physical performance testing: Testing the physical properties of aluminum veneer, such as strength, hardness, corrosion resistance, etc.

2. Appearance quality inspection: Inspect the appearance of aluminum veneer, such as color, texture, flatness, etc.

3. Coating quality testing: Testing the coating of aluminum veneer, such as glossiness, adhesion, etc.

5、 Packaging and transportation

1. Packaging: Pack the aluminum veneer to protect it from damage during transportation.

2. Transportation: Transport the aluminum veneer according to the customer's requirements to ensure its timely arrival at the construction site.

The production process of aluminum veneer manufacturers includes raw material procurement and preparation, processing and forming, surface treatment, quality inspection, packaging, and transportation. In the actual operation process, it is necessary to follow relevant norms and standards for operation and management, strengthen communication and collaboration, and improve work efficiency and quality level. We also need to pay attention to issues such as environmental protection and energy conservation, continuously innovate and improve products and services, and meet the needs of customers and the expectations of society.

Customer service QQ

Customer service QQ