Industry information

Company News

- Market prospects for customized aluminum veneer: vast development space

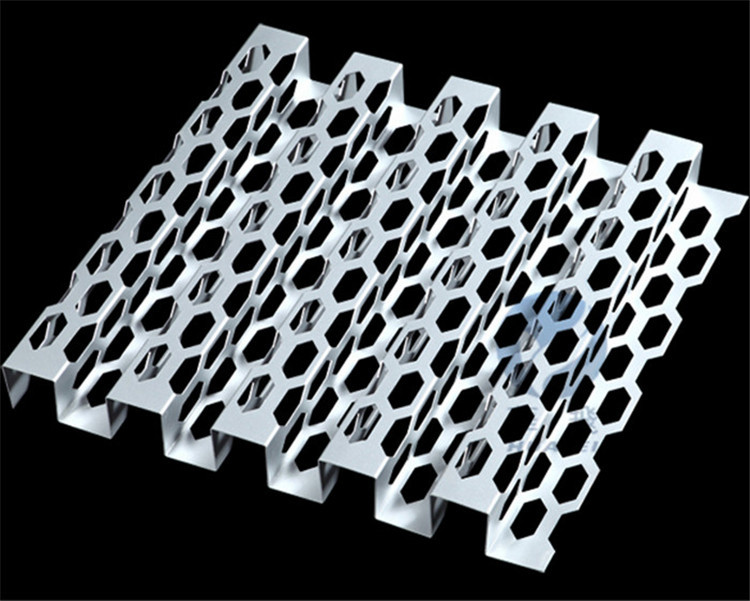

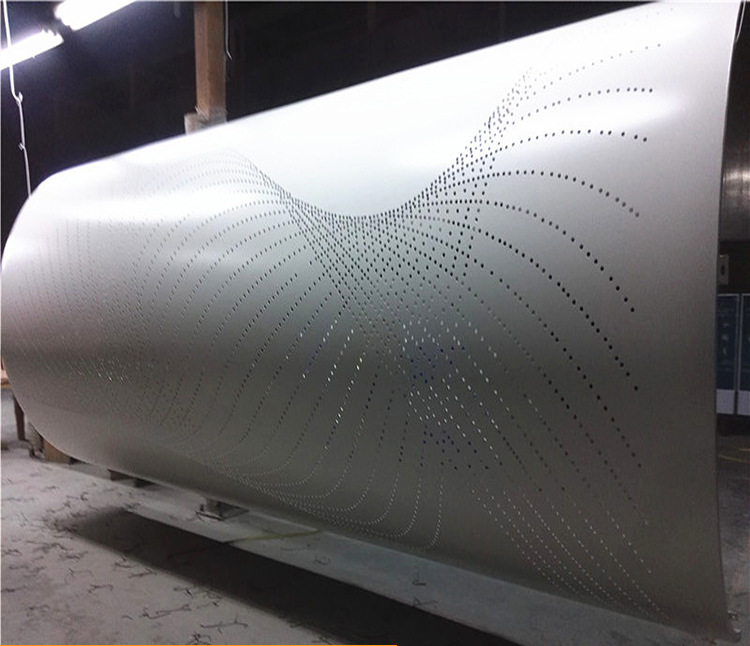

- Punched aluminum veneer: a fashionable choice for modern architecture. How much do you know about it?

- Ancient charm and modern style, carved aluminum veneer: an art that blends modernity and tradition

- Punched aluminum veneer: the finishing touch of architectural aesthetics

- Aluminum veneer customization, creating a new trend of personalized space

Industry dynamics

- Aluminum veneer customization, creating a new trend of personalized space

- Fluorocarbon aluminum veneer: the fashionable new favorite of future architecture

- Aluminum veneer: a fresh breeze in the construction industry, your new favorite for walls?

- Fluorocarbon aluminum veneer: the fashionable new favorite in the aluminum industry

- Aluminum veneer customization, creating a new trend of personalized space

Frequently asked questions

- How to determine the quantity and size of customized aluminum veneer?

- How to improve the fire resistance of aluminum veneer?

- How to improve the insulation performance of aluminum veneer?

- How to use and maintain aluminum veneer reasonably?

- How to store and transport aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

What issues should be noted during the installation process of aluminum veneer?

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: February 27, 2025 19:48:42

- Click:0

Aluminum veneerIt is a material widely used in fields such as construction and decoration, and there are many issues that need to be noted during its installation process. The following will provide a detailed introduction to the issues that need to be noted during the installation process of aluminum veneer and their solutions.

1. Check the quality issues of aluminum veneer

Before installing aluminum veneer, it is necessary to conduct a quality inspection of the aluminum veneer to ensure that its surface has no obvious damage, deformation, cracks, or other issues. It is also necessary to check whether the size of the aluminum veneer meets the design requirements, and whether the material of the aluminum veneer meets the standards. If any quality problems are found with the aluminum veneer, it should be replaced or repaired in a timely manner.

1. Choose the appropriate installation method

There are many installation methods for aluminum veneer, such as dry hanging method, wet bonding method, point bonding method, etc. When choosing the installation method, it should be based on the actual situation and design requirements, and operated strictly in accordance with relevant specifications.

1. Ensure the safety of the construction site

During the installation of aluminum veneer, it is necessary to ensure the safety of the construction site. Especially when working at heights, attention should be paid to the installation of safety protection measures, such as safety belts, guardrails, etc. Attention should also be paid to the safe use of construction tools, such as electric drills, cutting machines, etc.

1. Pay attention to the effects of temperature and humidity

During the installation process of aluminum veneer, temperature and humidity are important factors affecting its service life and aesthetics. When installing aluminum veneer, attention should be paid to the temperature and humidity of the environment to avoid damage or discoloration of the aluminum veneer due to environmental factors.

1. Strengthen maintenance and upkeep work

After the installation of aluminum veneer is completed, it is necessary to strengthen maintenance and upkeep work to extend its service life and aesthetics. Specific measures include regularly cleaning the surface of aluminum veneer, preventing pollution and corrosion, and avoiding collisions with heavy objects. New materials and technologies such as self-cleaning coatings and antibacterial materials can also be used to improve the durability and aesthetics of aluminum veneer.

There are many issues that need to be considered and resolved during the installation process of aluminum veneer from multiple perspectives. Enterprises should strengthen the quality control and management of aluminum veneer, strictly follow relevant specifications for construction and maintenance work, to ensure the quality and safety performance of products. Attention should also be paid to the safety awareness and skill training of employees to ensure the safety and smooth progress of the construction process.

Customer service QQ

Customer service QQ