Industry information

Company News

- Punched aluminum veneer: the fashionable choice in modern architecture?

- Carved Aluminum Veneer: Aluminum Art, New Style of Architecture

- Punched aluminum veneer: a perfect combination of fashion and practicality

- Fluorocarbon aluminum veneer: the new darling of modern architecture?

- Aluminum veneer customization, creating a new trend of personalized space

Industry dynamics

- Aluminum veneer customization, creating a new trend of personalized space

- Environmental Protection and Sustainable Development of Aluminum Veneer

- High quality building ceiling aluminum veneer makes buildings more charming

- Aluminum veneer punching, perfect integration of art and craftsmanship

- Punched aluminum veneer: the finishing touch of modern architecture?

Frequently asked questions

- How to use aluminum veneer for innovative design?

- How to solve the environmental problems in the production process of aluminum veneer?

- How to determine the quantity and size of customized aluminum veneer?

- How to improve the fire resistance of aluminum veneer?

- How to distinguish the quality of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Practice and Innovation of Aluminum Veneer Punching Process in Curtain Wall Decoration

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: February 28, 2025 20:25:42

- Click:0

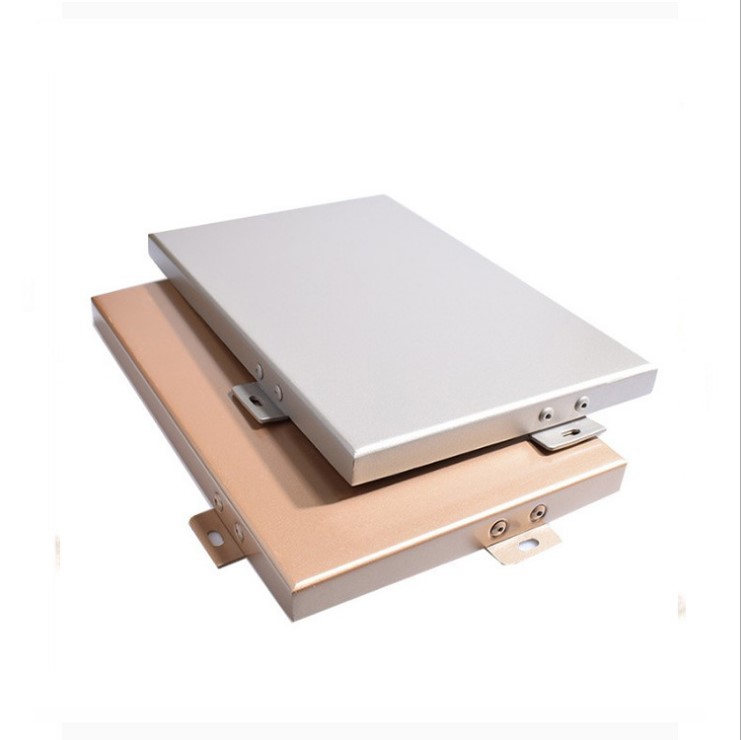

With the continuous development of the construction industry, curtain wallsAluminum veneerGradually becoming an important decorative material. Traditional aluminum veneer can no longer meet people's requirements for aesthetics and artistry. The application of aluminum veneer punching technology is also receiving increasing attention from people. Next, let's introduce the practice and innovation of aluminum veneer punching technology in curtain wall decoration.

1、 Application of Punching Process in Curtain Wall Decoration

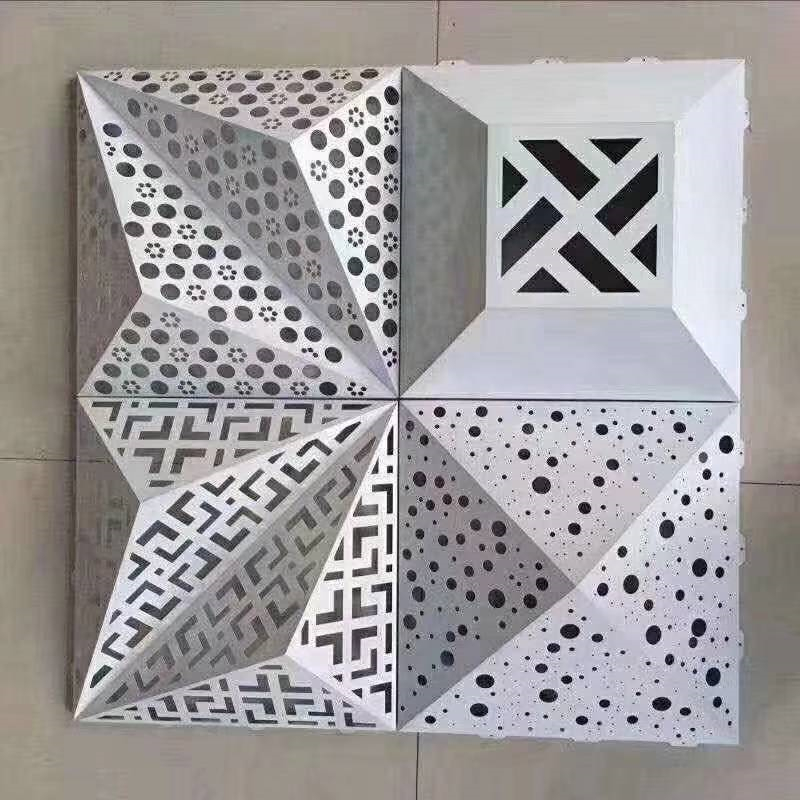

Aluminum veneer punching process is a technique of punching holes of different shapes and sizes on aluminum veneer through mechanical equipment. This technology can enable aluminum veneers to exhibit unique styles and characteristics, enhancing the artistic and cultural significance of buildings. In curtain wall decoration, aluminum veneer punching technology can be used to produce aluminum veneers of various shapes and colors, making them more in line with the overall style and design requirements of the building.

2、 Practice of Punching Process in Curtain Wall Decoration

1. Design a reasonable punching pattern

When decorating curtain walls, it is necessary to design reasonable punching patterns based on the overall style and design requirements of the building. Different punching patterns can present different styles and characteristics, thereby enhancing the artistic sense and cultural connotation of buildings.

2. Choose high-quality materials and equipment

When decorating curtain walls, it is necessary to choose high-quality materials and equipment to ensure the quality and efficiency of punching. For example, choosing high-strength, corrosion-resistant aluminum alloy materials and high-precision punching machines.

3. Control the accuracy and depth of punching

When decorating curtain walls, it is necessary to control the accuracy and depth of punching to avoid excessive punching or incomplete punching. This can be achieved by adjusting the parameters of the punching machine and optimizing the punching process flow.

3、 Innovation of Punching Process in Curtain Wall Decoration

1. Introduce intelligent control system

In order to improve the automation level and production efficiency of punching process, intelligent control system can be introduced. By connecting punching machines with computer systems, automated control and management of the punching process can be achieved, thereby improving production efficiency and product quality.

2. Manufacturing punching molds using 3D printing technology

Using 3D printing technology to manufacture punching molds can improve manufacturing accuracy and efficiency, while also reducing mold wear and waste. By converting the punching pattern into a digital model and then manufacturing it using a 3D printer, high-precision and high-quality punching mold manufacturing can be achieved.

4、 Case sharing

Let's take a look at a practical and innovative case of aluminum veneer punching technology in curtain wall decoration: a company designed a high-rise building in a commercial center of a city, and the exterior wall of the building used multiple punched aluminum veneers of different colors and shapes for combination and assembly. In order to meet the overall style and design requirements of the building, the company has adopted advanced intelligent control systems and new punching machines, and used 3D printing technology to manufacture high-precision and high-quality punching molds. Ultimately, high-quality and efficient curtain wall decoration effects were achieved, adding unique artistic charm to the building.

5、 Summary

The application of aluminum veneer punching technology in curtain wall decoration has broad prospects and development space. By designing reasonable punching patterns, selecting high-quality materials and equipment, and controlling the accuracy and depth of punching, high-quality and efficient curtain wall decoration effects can be achieved. In the future, with the continuous progress and innovation of technology, it is believed that the punching process of aluminum veneer will be more widely applied and developed. It also requires practitioners in the construction and decoration industry to constantly learn and explore in order to adapt to market demands and changes.

Customer service QQ

Customer service QQ