Industry information

Company News

- The charm of customized aluminum veneer: the perfect combination of innovation and personalization

- Ancient charm and modern style, carved aluminum veneer takes you through time and space

- Fluorocarbon aluminum veneer: the "fashionable coat" of modern architecture

- Carved aluminum veneer: a magnificent turn of aluminum art

- Carved aluminum veneer: a magnificent choice for modern architecture

Industry dynamics

- Fluorocarbon aluminum veneer: the fashion darling of the aluminum industry

- Waterproof and Thermal Insulation Effects of Outdoor Aluminum Curtain Walls

- 7 methods for addressing common issues with aluminum veneer

- Carved aluminum veneer: a perfect fusion of art and technology

- Aluminum veneer customization, creating a new trend of personalized space

Frequently asked questions

- How to identify the quality of aluminum veneer?

- How to use aluminum veneer for innovative design?

- How to determine the quantity and size of customized aluminum veneer?

- How to distinguish the quality of aluminum veneer?

- How to store and transport aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Surface treatment technology and application of aluminum veneer

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: 2022-03-01 23:21:32

- Click:0

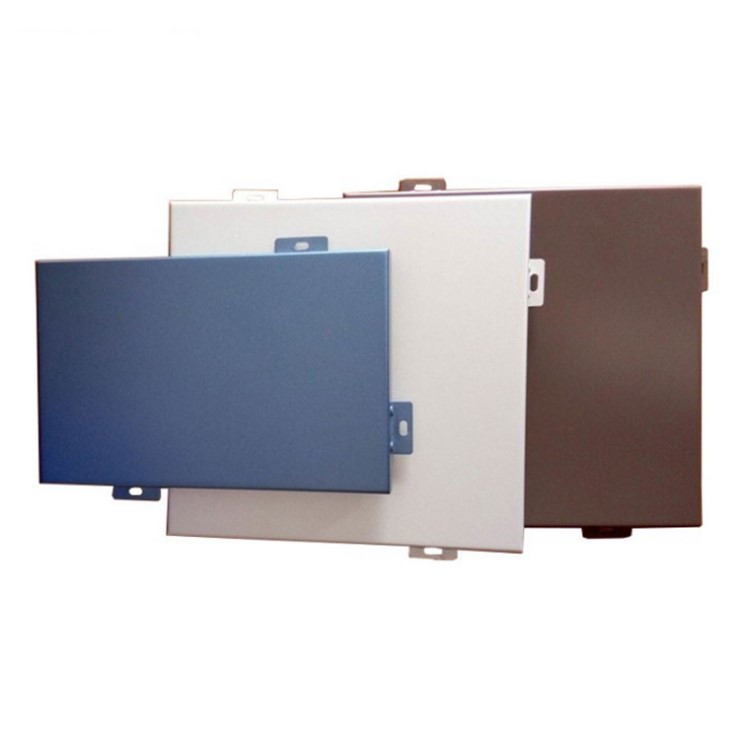

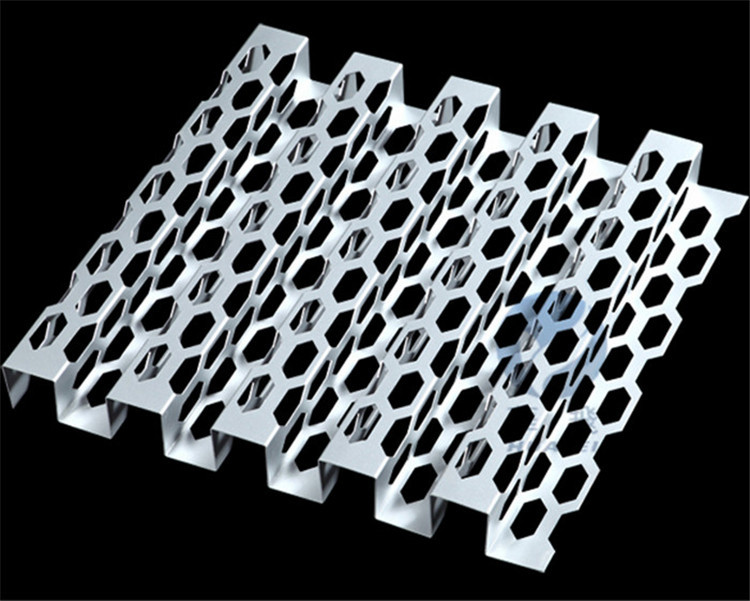

Aluminum veneerAs a new type of building material, it has the advantages of lightweight, high strength, and corrosion resistance. Its surface treatment technology is also one of the important factors affecting its use effect. The surface treatment technology and application of aluminum veneer will be introduced in detail below.

1、 Anodizing

Anodizing is a commonly used surface treatment technique for aluminum veneers, which can improve their corrosion resistance and decorative effect. Specifically, anodizing is the formation of an oxide film on the surface of aluminum veneer, giving it a certain degree of hardness and wear resistance. Anodizing can also be dyed and coated according to different needs to meet different decorative effect requirements.

2、 Powder coating

Powder coating is another commonly used surface treatment technique for aluminum veneer, which can improve the corrosion resistance and decorative effect of aluminum veneer. Specifically, powder coating is the process of applying a layer of powder coating onto the surface of aluminum veneer, followed by high-temperature baking to form the coating. This processing technology can make aluminum veneer have good corrosion resistance and decorative effect, while also allowing for color and texture selection according to different needs.

3、 Fluorocarbon spraying

Fluorocarbon spraying is a high-end surface treatment technology for aluminum veneer, which can improve the corrosion resistance and decorative effect of aluminum veneer. Specifically, fluorocarbon spraying is the process of applying a layer of fluorocarbon coating onto the surface of aluminum veneer, followed by high-temperature baking to form the coating. This processing technology can make aluminum veneer have good corrosion resistance and decorative effect, while also allowing for color and texture selection according to different needs. Fluorocarbon coatings also have good weather resistance and UV resistance, which can maintain a good appearance in outdoor environments.

4、 Application Fields

Aluminum veneer is widely used in fields such as exterior wall decoration, interior decoration, and advertising billboards due to its advantages of lightweight, high strength, and corrosion resistance. For example, using aluminum veneer in the exterior wall decoration of high-rise buildings can effectively resist the impact of natural disasters such as wind pressure and earthquakes, ensuring the safety and stability of the building; Using aluminum veneer in indoor decoration can create a simple and fashionable decorative effect; The use of aluminum veneer in billboard production can improve the durability and aesthetics of billboards.

The surface treatment technology of aluminum veneer has a significant impact on its usage effect. By selecting appropriate surface treatment techniques, the corrosion resistance, decorative effect, and service life of aluminum veneer can be improved. In the future, with the development of technology and social progress, aluminum veneer will play an increasingly important role in more fields.

Customer service QQ

Customer service QQ