Industry information

Company News

- The fashion comeback of aluminum veneer: a journey of transformation from tradition to modernity

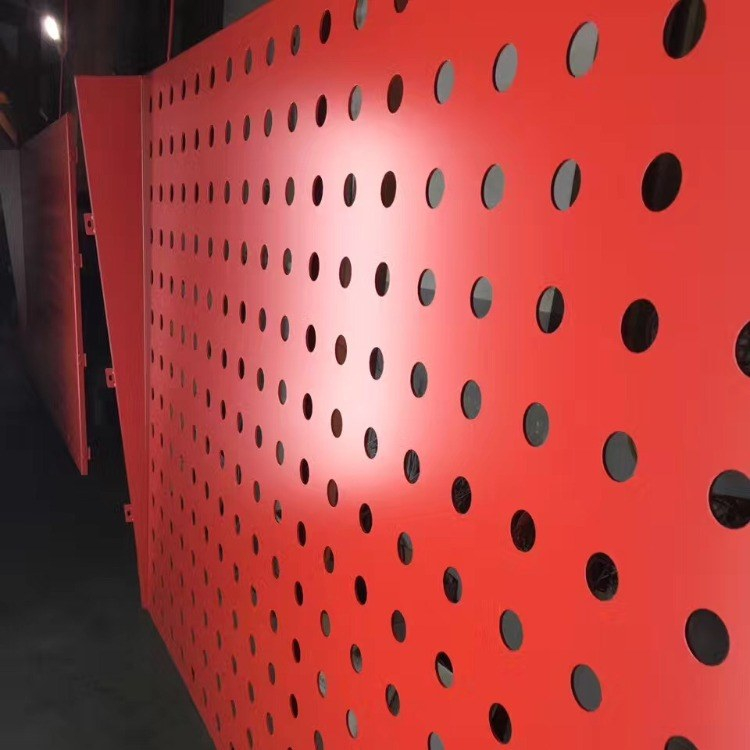

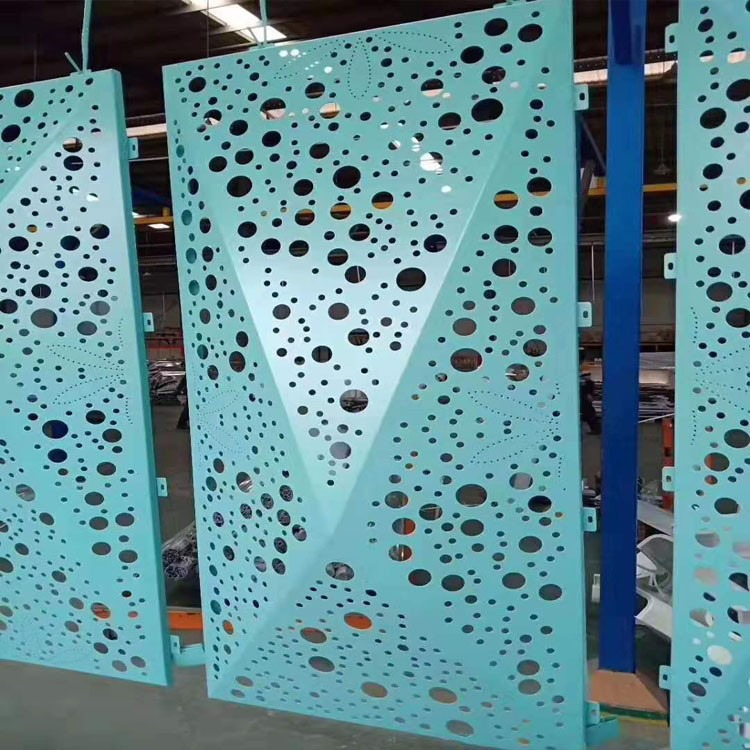

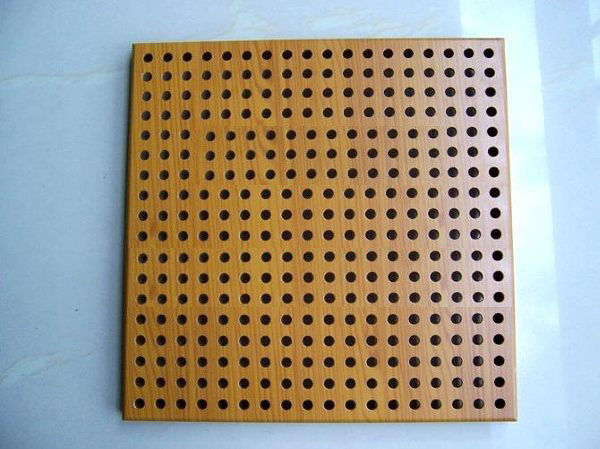

- Punched aluminum veneer: a fashionable "sunshade" for modern architecture

- Fluorocarbon aluminum veneer: the "fashionable coat" of modern architecture

- Aluminum veneer: a modern interpretation of architectural aesthetics

- Carved aluminum veneer: a delicate interpretation of architectural aesthetics

Industry dynamics

- The Consumer Market and Consumer Behavior of Aluminum Veneer Consumers' Awareness of Aluminum Veneer

- Surface treatment technology and application of aluminum veneer

- Aluminum veneer, low-key luxury in modern architecture

- Customize exclusive aluminum veneer to enhance building quality

- Aluminum veneer customization, creating a new trend of personalized space

Frequently asked questions

- How to use and maintain aluminum veneer reasonably?

- How to store and transport aluminum veneer?

- How to determine the quantity and size of customized aluminum veneer?

- How to solve the environmental problems in the production process of aluminum veneer?

- How to improve the fire resistance of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

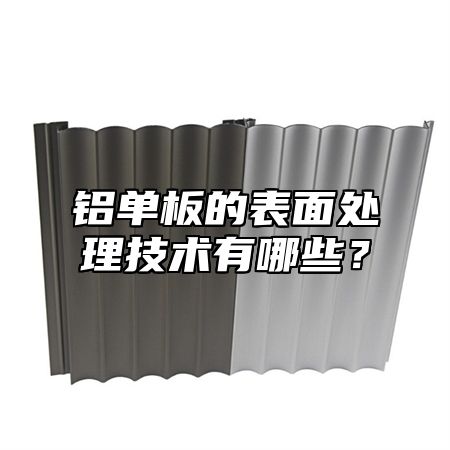

What are the surface treatment techniques for aluminum veneer?

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: March 1, 2025 16:05:16

- Click:0

Aluminum veneerIt is a common building material, and its surface treatment technology is very important for improving its appearance and service life. Below, we will provide a detailed introduction to the surface treatment technology of aluminum veneer.

1. Anodizing treatment

Anodizing treatment is a commonly used surface treatment technique for aluminum veneer, which forms a dense oxide film on the surface of the aluminum veneer through electrolytic oxidation, thereby improving the corrosion resistance and wear resistance of the aluminum veneer. Anodizing treatment can also create various colors and textures on the surface of aluminum veneer, enhancing its decorative properties.

1. Spray treatment

Spray coating treatment is a technique of spraying paint on the surface of aluminum veneer, which can make the surface of aluminum veneer present various colors and textures. The advantages of spray coating treatment are simple process, low cost, and suitable for some mid to low grade building decoration materials. However, due to the large amount of exhaust gas and wastewater generated during the spraying process, it has a certain degree of pollution to the environment.

1. Roll drawing treatment

Roller drawing treatment is a technique of forming metal textures on the surface of aluminum veneer through rolling and drawing. This processing method can give the surface of aluminum veneer a metallic luster and texture effect, improving its decorative quality. The advantages of roller drawing treatment are simple process, low cost, and suitable for some mid to low grade building decoration materials. However, due to the rough surface of aluminum veneer caused by roll drawing treatment, it is not suitable for high-end building decoration materials.

1. Fluorocarbon spraying treatment

Fluorocarbon spraying treatment is a technique of spraying fluorocarbon coating on the surface of aluminum veneer, which can make the surface of aluminum veneer exhibit strong weather resistance and corrosion resistance. Fluorocarbon coatings have excellent weather resistance and UV resistance, and can be used for a long time in outdoor environments. The advantages of fluorocarbon spraying treatment are complex process and high cost, which is suitable for some high-end building decoration materials. However, fluorocarbon coatings are expensive and require regular maintenance and replacement.

The surface treatment technology of aluminum veneer is very important for improving its appearance and service life. By selecting appropriate surface treatment techniques, aluminum veneer can achieve better decorative effects and service life.

Customer service QQ

Customer service QQ