Industry information

Company News

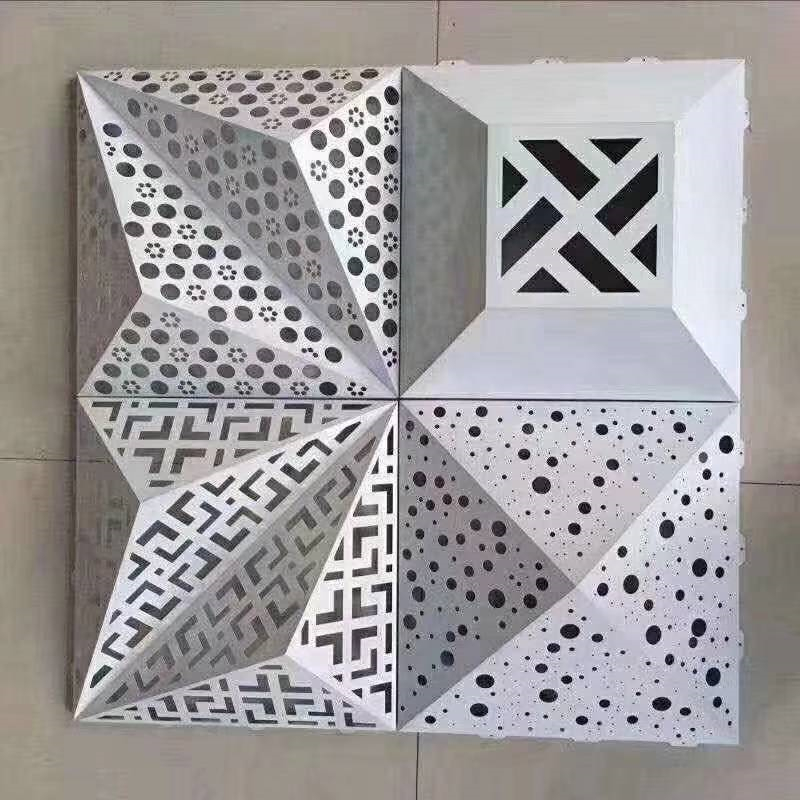

- Punched aluminum veneer: the new favorite for creating fashionable spaces

- Aluminum plate new fashion: punched aluminum veneer, creating a unique spatial aesthetic

- Fluorocarbon aluminum veneer: the new darling of architectural aesthetics

- Fluorocarbon aluminum veneer: not just aluminum, but also the beauty of architecture

- Aluminum veneer: the fashionable choice for modern architecture

Industry dynamics

- Ancient charm and modern style, carved aluminum veneer interprets modern aesthetics

- Insight into the wonderful uses of punched aluminum veneer

- Aluminum veneer customization, creating the art of personalized space

- Design and Construction Techniques Sharing of Carved Perforated Aluminum Veneer

- Punched aluminum veneer: a fashionable choice for modern architecture

Frequently asked questions

- How to store and transport aluminum veneer?

- How to use and maintain aluminum veneer reasonably?

- How to identify the quality of aluminum veneer?

- How to determine the quantity and size of customized aluminum veneer?

- How to solve the environmental problems in the production process of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Introduction to Fire Performance of Aluminum Veneer

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: March 2, 2025 05:58:09

- Click:0

Aluminum veneerAs a new type of building material, it has the advantages of lightweight, high strength, and corrosion resistance, and has been widely used in the construction industry. The fire resistance performance of aluminum veneer has always been one of the focuses of people's attention. Below, we will provide a detailed introduction to the fire resistance performance of aluminum veneer.

1、 Combustion characteristics of aluminum veneer

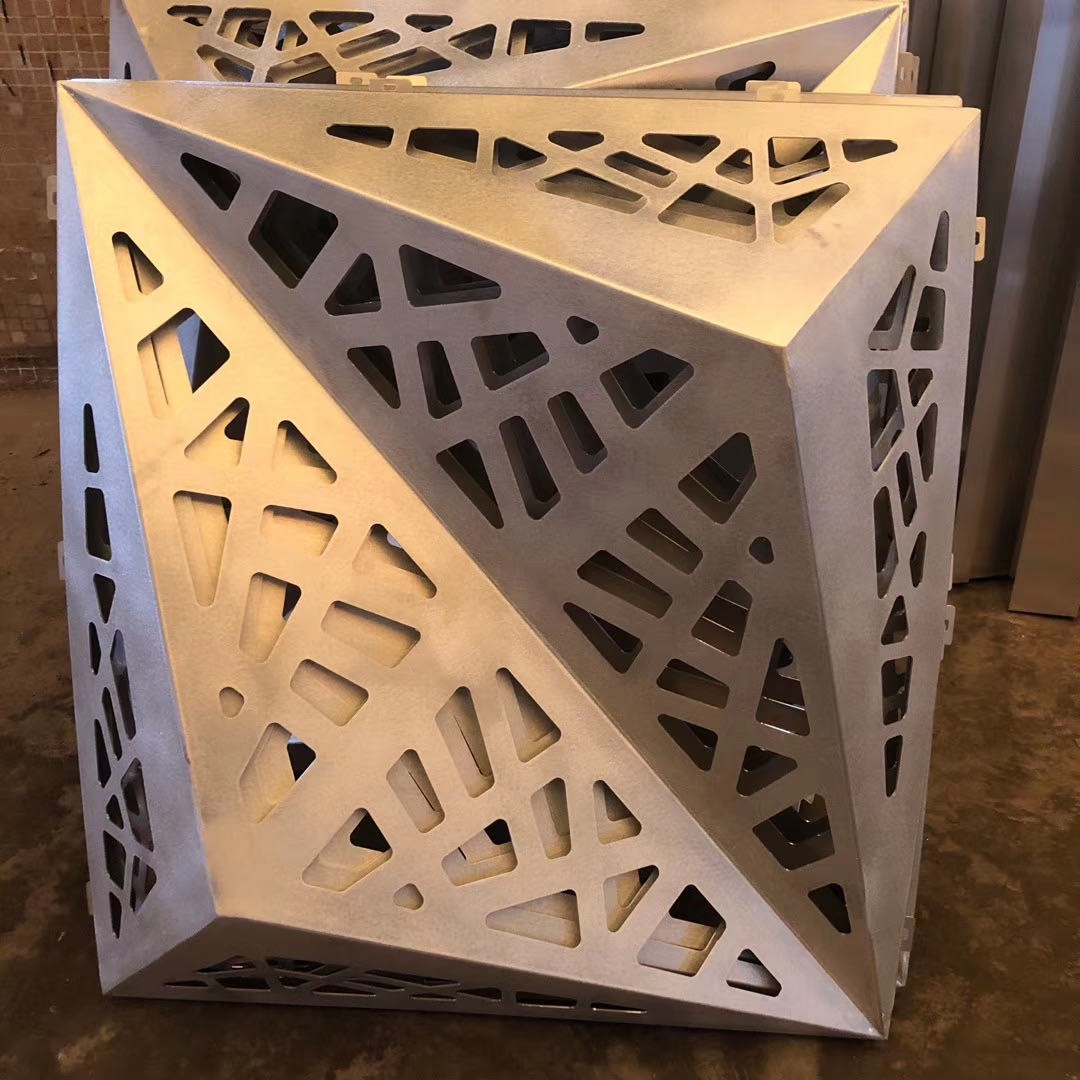

Aluminum veneer is made of aluminum alloy material, mainly composed of aluminum and magnesium. At high temperatures, aluminum and magnesium react with oxygen, producing a large amount of heat and flames. The combustion characteristics of aluminum veneer depend on factors such as its surface treatment method and thickness.

2、 Surface treatment methods for aluminum veneer

To improve the fire resistance of aluminum veneer, the following surface treatment methods can be used:

1. Anodizing treatment: By electrolysis, a layer of oxide film is formed on the surface of aluminum veneer, thereby improving its corrosion resistance and fire resistance.

2. Fluorocarbon spraying treatment: Spraying a layer of fluorocarbon coating on the surface of aluminum veneer can form a hard, wear-resistant, and corrosion-resistant protective film, thereby improving the corrosion resistance and fire resistance of aluminum veneer.

3. Polyester coating treatment: Spraying a layer of polyester coating on the surface of aluminum veneer can form a waterproof, moisture-proof, and anti-corrosion protective film, thereby improving the corrosion resistance and fire resistance of aluminum veneer.

3、 Application fields of aluminum veneer

Due to its excellent fire resistance, aluminum veneer is widely used in various construction fields, such as airports, stations, sports venues, conference centers, etc. Aluminum veneer can also be used in outdoor billboards, roof systems, exterior wall decoration, and other fields.

4、 Maintenance methods for aluminum veneer

In order to extend the service life of aluminum veneer and improve its fire resistance, regular maintenance work is required. The specific methods include:

1. Regularly clean the surface of aluminum veneer to remove dust and dirt;

2. Avoid using acidic or alkaline cleaning agents to clean the surface of aluminum veneer;

3. Avoid prolonged exposure to sunlight or rainwater;

4. When installing and disassembling aluminum veneer, be careful not to damage its surface.

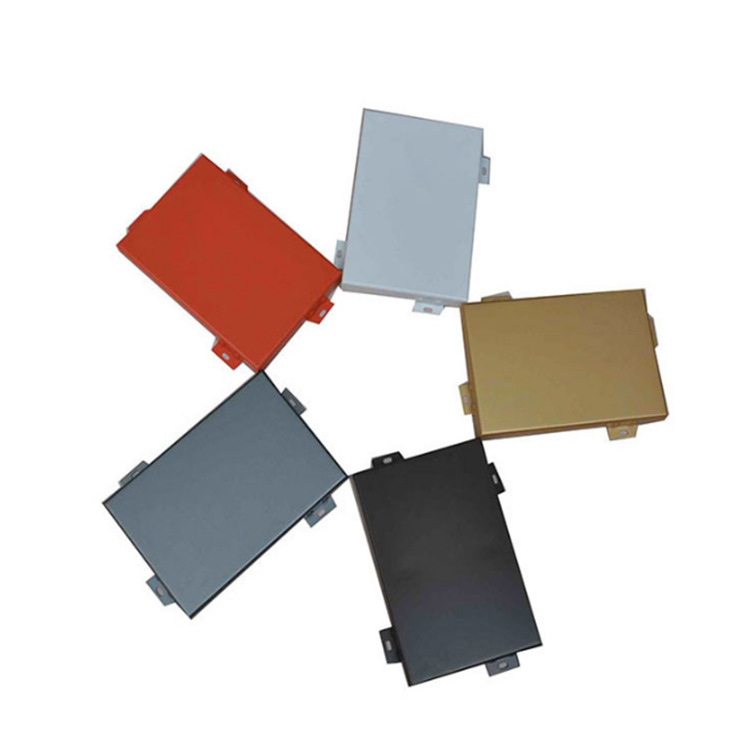

5、 Fire rating classification of aluminum veneer

According to the national standard GB/T8624-2012 "Classification Method for Combustion Performance of Building Materials", building materials are divided into five levels: A1, A2, B1, B2, and C. A1 grade is non combustible material, A2 grade is non combustible material, B1 grade is combustible material, B2 grade is flammable material, and C grade is extremely flammable material. The fire rating of aluminum veneer depends on factors such as its surface treatment method and thickness. Generally speaking, aluminum veneer treated with anodizing or fluorocarbon spraying can achieve a fire rating of B1 or B2.

Aluminum veneer has excellent fire resistance and its fire rating can be further improved through surface treatment. Regular maintenance work is also an important measure to ensure the service life and fire resistance of aluminum veneer.

Customer service QQ

Customer service QQ