Industry information

Company News

- Customized aluminum veneer to create your own unique aesthetic space

- Carved aluminum veneer: a magnificent transformation of aluminum art

- Aluminum veneer: an elegant element in modern architecture

- Ancient charm and modern style, carved aluminum veneer interprets modern aesthetics

- The fashion comeback of aluminum veneer: a journey of transformation from tradition to modernity

Industry dynamics

- Interpretation of Market Regulation on the Price and Supply Demand Relationship of Aluminum Veneer

- Customized aluminum veneer, creating a new trend of personalized space

- Punched aluminum veneer: the new darling of architectural art, revealing its charm!

- Introduction to the advantages and functions of stone patterned aluminum veneer for curtain walls

- Economic analysis of aluminum veneer price

Frequently asked questions

- How to improve the insulation performance of aluminum veneer?

- How to solve the environmental problems in the production process of aluminum veneer?

- How to improve the fire resistance of aluminum veneer?

- How to use aluminum veneer for innovative design?

- How to distinguish the quality of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Production process and equipment selection of aluminum veneer

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: March 9, 2025 16:49:14

- Click:0

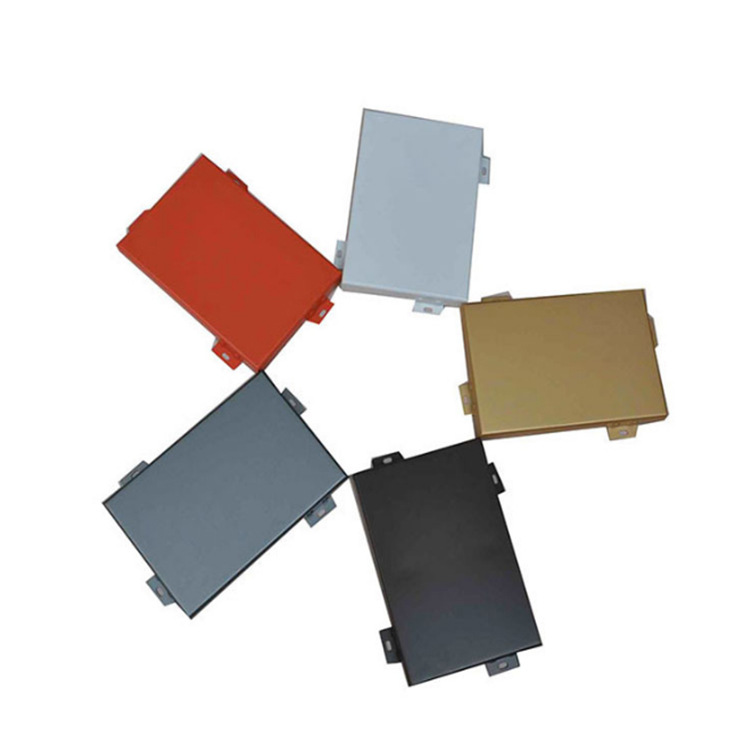

Aluminum veneerAs a new type of building material, the selection of production processes and equipment has a crucial impact on product quality and production efficiency. This article will provide a detailed introduction to the selection method of aluminum veneer from two aspects: production process and equipment.

1、 Selection of Production Process

1. Spray coating process

Spray coating process is a common surface treatment method for aluminum veneer, which can make the surface of aluminum veneer have good corrosion resistance and decorative properties. When choosing a spraying process, the following factors need to be considered: the selection of spraying materials, the performance and stability of spraying equipment, and the control of spraying environment. The selection of spraying materials is one of the most critical factors, and the appropriate spraying materials should be chosen based on the specific use and environment of the aluminum veneer.

1. Roll pressing process

Roll pressing technology is a relatively advanced surface treatment method for aluminum veneer, which can make the surface of aluminum veneer have better flatness and glossiness. When choosing the rolling process, the following factors need to be considered: the model and performance of the rolling machine, the control of rolling speed and pressure, and the surface treatment after rolling. The selection and performance of roller presses are one of the most critical factors, and the appropriate roller press should be selected based on the specific application and production scale of aluminum veneer.

2、 Equipment selection

1. CNC machining equipment

Numerical control machining equipment is a modern production device that can achieve precise machining and cutting of aluminum veneer. When choosing CNC machining equipment, the following factors need to be considered: equipment accuracy and stability, equipment processing range and capability, equipment usability and maintainability, etc. The accuracy and stability of the equipment are one of the most critical factors, and suitable CNC machining equipment should be selected based on the specific size and shape of the aluminum veneer.

1. Spraying equipment

Spraying equipment is a commonly used surface treatment device that can make the surface of aluminum veneer have good corrosion resistance and decorative properties. When choosing spraying equipment, the following factors need to be considered: the number and type of nozzles of the equipment, the spraying speed and stability of the equipment, the control system and operating interface of the equipment, etc. The number and type of nozzles in the equipment are one of the most critical factors, and the appropriate spraying equipment should be selected according to the specific requirements of the aluminum veneer.

The production process and equipment selection of aluminum veneer have a crucial impact on its product quality and production efficiency. In the selection process, the specific purpose and usage environment of aluminum veneer should be fully considered, and reasonable selection and configuration should be made according to the actual situation.

Customer service QQ

Customer service QQ