Industry information

Company News

- Fluorocarbon aluminum veneer: the fashion darling of the aluminum industry

- Aluminum veneer customization, creating an exclusive aesthetic for your space

- Unveiling punched aluminum veneer: the new favorite of lightweight and fashionable decoration

- Fluorocarbon aluminum veneer: a shining pearl in modern architecture!

- The new trend of aluminum veneer decoration brings a fresh look to home decor!

Industry dynamics

- Fluorocarbon aluminum veneer: the fashionable new favorite in the aluminum industry

- The required material for engineering construction is 1.5mm aluminum veneer to improve building quality

- Aluminum veneer customization, creating personalized spatial aesthetics

- How to create a unique exterior wall with aluminum veneer?

- The application value of hyperbolic aluminum veneer in commercial buildings

Frequently asked questions

- How to solve the environmental problems in the production process of aluminum veneer?

- How to design customized aluminum veneer?

- How to improve the insulation performance of aluminum veneer?

- How to store and transport aluminum veneer?

- How to distinguish the quality of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Production process and technical requirements of aluminum veneer

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: March 11, 2025 23:00:09

- Click:0

Aluminum veneerAs a new type of building material, its production process and technical requirements have a certain degree of complexity. Let's take a look at the production process and technical requirements of aluminum veneer together.

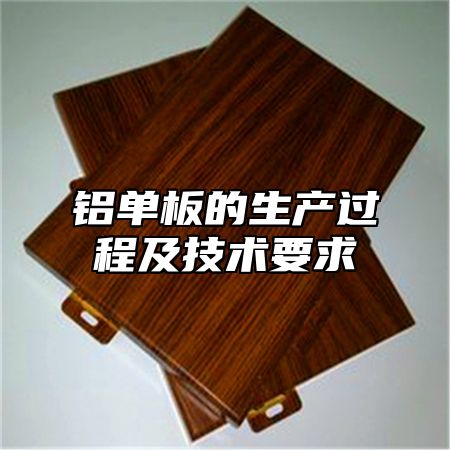

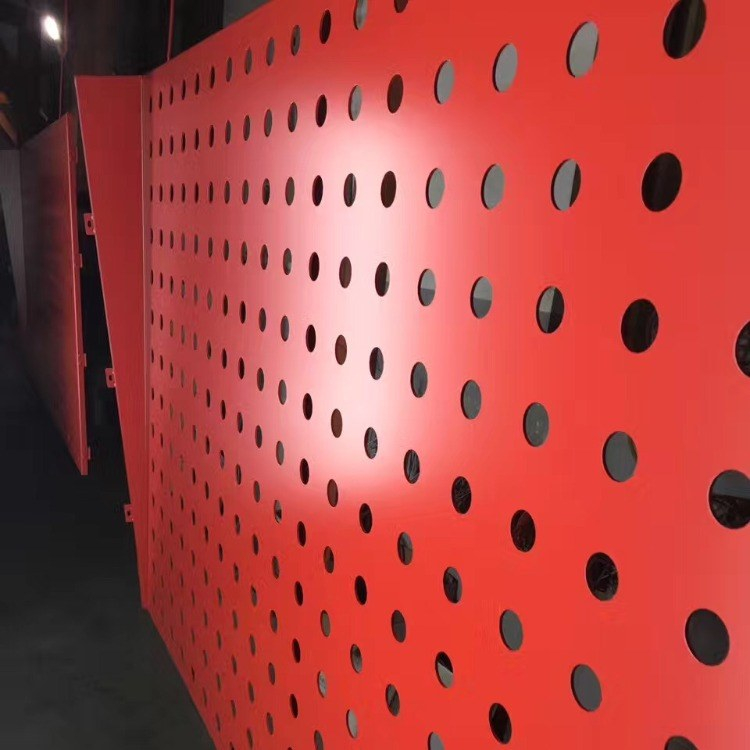

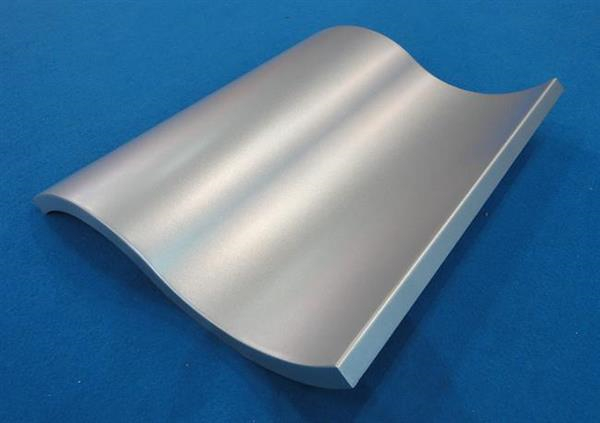

The production process of aluminum veneer mainly includes raw material procurement, sheet metal processing, surface treatment, spraying and other links. In terms of raw material procurement, it is necessary to choose high-quality aluminum materials as raw materials and conduct strict quality inspections. In terms of sheet metal processing, advanced CNC machining equipment is needed to cut, bend, and punch aluminum materials. In terms of surface treatment, professional surface treatment methods such as anodizing, electrophoretic coating, spraying, etc. are needed to improve the durability and aesthetics of aluminum veneer. In terms of spraying, efficient spraying equipment and coatings are needed to ensure the uniformity and vivid color of the aluminum veneer surface.

The technical requirements for aluminum veneer mainly include strength, durability, corrosion resistance, fire resistance, and other aspects. In terms of strength, aluminum veneer needs to have high tensile and compressive strength to ensure its stability and safety during use. In terms of durability, aluminum veneer needs to have good anti-aging and corrosion resistance to extend its service life. In terms of corrosion resistance, aluminum veneer needs to have good rust prevention and corrosion resistance to prevent it from being affected by oxidation and corrosion during use. In terms of fire resistance, aluminum veneer needs to have good fire resistance to ensure its safety and reliability during use.

In addition, the production process of aluminum veneer also needs to comply with relevant environmental requirements. In the production process, a series of measures need to be taken to reduce the emission of pollutants and waste of resources. For example, circular utilization can be used to treat and recycle wastewater, exhaust gas, etc. Energy conservation and emission reduction technologies can also be adopted to reduce energy consumption and carbon emissions.

The production process and technical requirements of aluminum veneer have a certain degree of complexity. Only by fully understanding these factors can high-quality aluminum veneer products be produced, providing guarantees for the quality and performance of buildings.

Customer service QQ

Customer service QQ