Industry information

Company News

- Customized aluminum veneer to create your own fashionable space

- Unveiling punched aluminum veneer: the fashionable choice in modern architecture

- Punched aluminum veneer: a fashion pioneer in the aluminum industry

- Punched aluminum veneer: the new darling of modern architecture!

- Fluorocarbon aluminum veneer: the "invisible warrior" of modern architecture

Industry dynamics

- Customize aluminum veneer to create a unique home style

- Carved aluminum veneer: a perfect fusion of art and craftsmanship

- Surface treatment technology and application of aluminum veneer

- Aluminum veneer customization, creating a new trend of personalized space!

- Waterproof and Thermal Insulation Effects of Outdoor Aluminum Curtain Walls

Frequently asked questions

- How to distinguish the quality of aluminum veneer?

- How to design customized aluminum veneer?

- How to store and transport aluminum veneer?

- How to improve the fire resistance of aluminum veneer?

- How to solve the environmental problems in the production process of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Production process and cost-benefit analysis of aluminum veneer

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: March 9, 2025 23:00:07

- Click:0

Aluminum veneerAs a new type of building material, its production process and cost-effectiveness are also important factors affecting its development. Below, we will provide a detailed introduction to the production process and cost-benefit analysis of aluminum veneer.

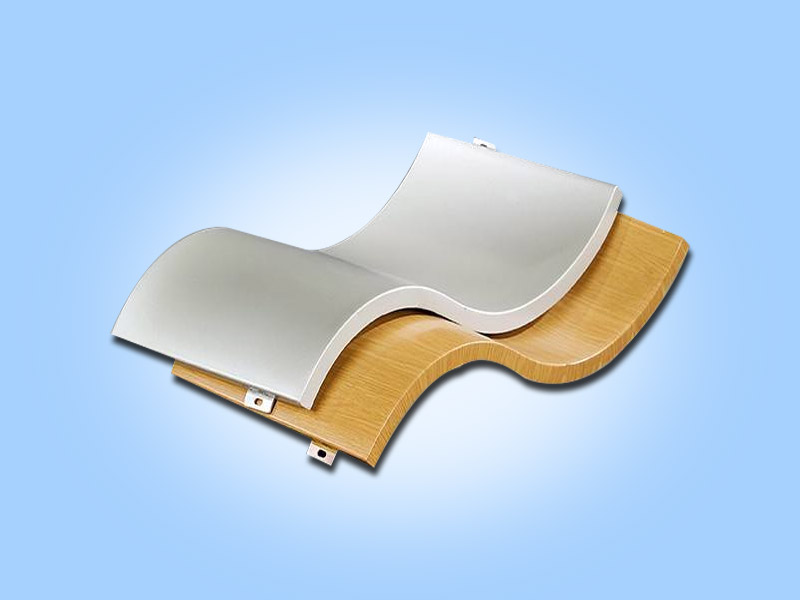

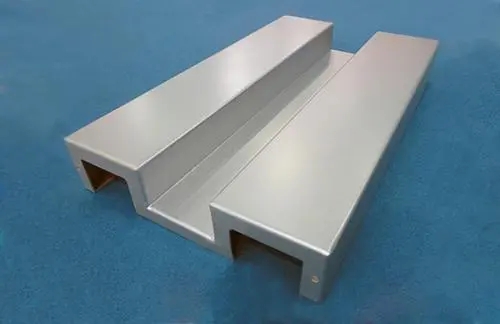

The production process of aluminum veneer mainly includes raw material procurement, melting, rolling, surface treatment and other links. Raw material procurement is the foundation for ensuring product quality, and it is necessary to choose high-quality raw material suppliers; Smelting is the process of heating aluminum to a certain temperature to melt it, and then rolling it into shape through a mold; Surface treatment is the process of spraying, anodizing, and other treatments on rolled aluminum veneers to improve their aesthetic appearance and corrosion resistance.

The cost-effectiveness of aluminum veneer is also one of the important factors affecting its market competitiveness. The cost of aluminum veneer mainly includes raw material costs, labor costs, equipment depreciation expenses, energy consumption expenses, etc. The cost of raw materials is the main component of the cost of aluminum veneer, accounting for a relatively large proportion; Labor costs and equipment depreciation expenses also account for a certain proportion; The energy consumption cost is an inevitable cost in the production process of aluminum veneer.

The cost-effectiveness of aluminum veneer also needs to be analyzed based on the actual situation. For example, by optimizing production processes and equipment, energy consumption and waste rates can be reduced, thereby lowering production costs; By strengthening employee training and management, improving employee skills and work efficiency, labor costs can be reduced; By strengthening brand building and management innovation, product added value and market competitiveness can be improved, thereby increasing profit margins.

The production process and cost-effectiveness of aluminum veneer are important factors affecting its development. By continuously innovating and applying new technologies, strengthening production management and resource recycling, the market competitiveness and market share of aluminum veneer can be further improved, achieving maximum investment return. Both investors and production enterprises need to closely monitor the new technologies and trends in the aluminum veneer industry, adjust their business strategies and investment directions in a timely manner, in order to seize market opportunities.

Customer service QQ

Customer service QQ