Industry information

Company News

- Aluminum veneer: lightweight building material, shaping the beauty of modern architecture

- Fluorocarbon aluminum veneer: the "fashionable coat" of modern architecture

- Aluminum veneer customization, creating a new trend of personalized space

- Aluminum veneer customization, creating a new trend of personalized space!

- Aluminum veneer: the new darling of modern architecture. How much do you know about it?

Industry dynamics

- Aluminum veneer customization, creating a new trend of personalized space

- Analysis of the application value of 3mm perforated aluminum veneer, a new favorite in the furniture industry

- What is the market positioning of aluminum veneer?

- Aluminum veneer, the hidden star of the construction industry

- The production process and characteristics of stone patterned aluminum veneer for curtain walls

Frequently asked questions

- How to use and maintain aluminum veneer reasonably?

- How to store and transport aluminum veneer?

- How to solve the environmental problems in the production process of aluminum veneer?

- How to determine the quantity and size of customized aluminum veneer?

- How to improve the insulation performance of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

What is the production cost of aluminum veneer?

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: March 14, 2025 00:09:47

- Click:0

Aluminum veneerAs a common building material, its production cost is one of the important considerations for customers when choosing to use this product. This article will provide a detailed introduction to the production cost of aluminum veneer.

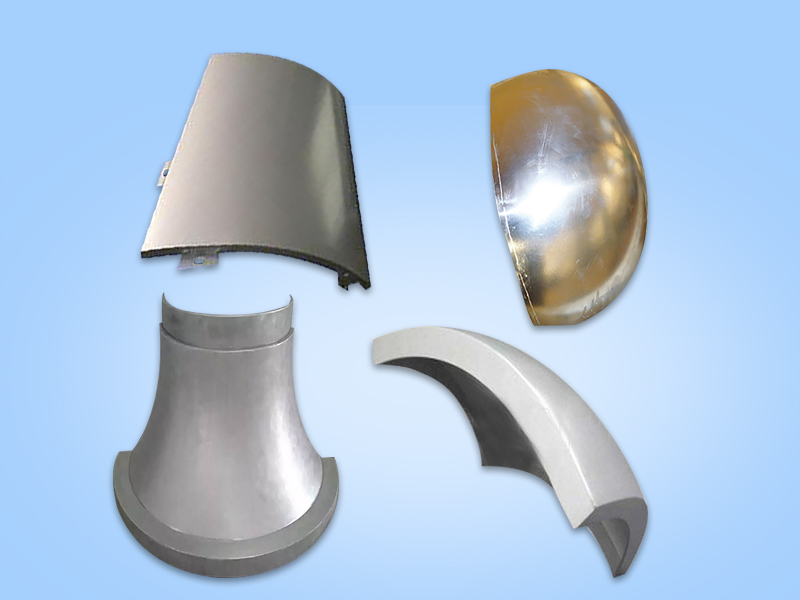

1、 Raw material cost

The main raw materials for aluminum veneer are aluminum alloy sheets and surface treatment materials. The prices of these raw materials are influenced by factors such as market supply and demand, production costs, etc., resulting in significant price fluctuations. Generally speaking, the price of aluminum is higher than that of surface treatment materials, so the total raw material cost of aluminum veneer will also be affected. The prices of aluminum alloy sheets of different types and specifications also vary.

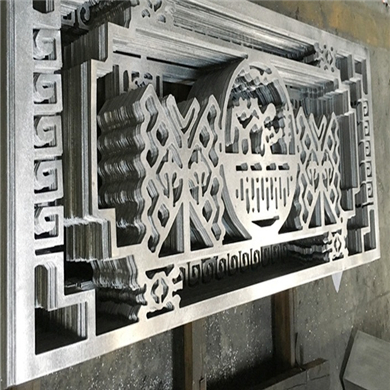

2、 Production process cost

The production process of aluminum veneer includes multiple steps such as cutting, surface treatment, welding, assembly, and subsequent processing. These processes require a significant amount of manpower, material resources, and financial resources, thereby increasing the production cost of aluminum veneer. The equipment and technology required for cutting, processing, and surface treatment have a significant impact on production costs. In addition, the production efficiency and quality of different processes can also affect the cost of aluminum veneer.

3、 Labor cost

The production process of aluminum veneer requires a large amount of manual participation, including operating machines, inspecting product quality, packaging and transportation. The labor cost accounts for an important component of the production cost of aluminum veneer. The level of labor costs depends on factors such as workers' wage levels, working hours, and work intensity. In a fiercely competitive market environment, companies may take measures such as layoffs and improving work efficiency in order to reduce costs.

4、 Equipment depreciation cost

Aluminum veneer production requires a large amount of equipment and machinery, which have a limited lifespan and require regular maintenance and replacement. The depreciation cost of equipment is an important component of the production cost of aluminum veneer. The size of equipment depreciation cost depends on factors such as the brand, model, and service life of the equipment.

5、 Other costs

In addition to the costs mentioned above, the production of aluminum veneer may also involve other costs such as energy consumption, transportation costs, taxes, etc. Although these costs are not direct production costs, they are also one of the factors that affect the total cost of aluminum veneer.

The production cost of aluminum veneer includes multiple aspects such as raw material cost, production process cost, labor cost, equipment depreciation cost, and other costs. In order to reduce the production cost of aluminum veneer, enterprises need to adopt advanced production processes and equipment, optimize production processes and management modes, and improve production efficiency and quality. We also need to focus on product innovation and research and development, constantly innovating and meeting the ever-changing needs of customers.

Customer service QQ

Customer service QQ