Industry information

Company News

- Fluorocarbon aluminum veneer: not just aluminum, but also the beauty of architecture

- Aluminum veneer customization, creating a new trend of personalized space

- Punched aluminum veneer: the new darling of modern architecture!

- Detail processing of customized aluminum veneer: showcasing quality in every aspect

- Carved aluminum veneer: the unique charm of modern architecture

Industry dynamics

- Aluminum veneer customization, creating exclusive space aesthetics

- Aluminum veneer reveals the 'invisible hero' of modern architecture

- Manufacturing process and process flow of roller coated ceiling aluminum veneer

- Aluminum veneer: understated luxury in modern architecture

- 2. New trend of aluminum veneer: carved aesthetics, taste life. 3 Carved aluminum veneer, home decor

Frequently asked questions

- How to determine the quantity and size of customized aluminum veneer?

- How to store and transport aluminum veneer?

- How to identify the quality of aluminum veneer?

- How to improve the fire resistance of aluminum veneer?

- How to distinguish the quality of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

What are the production processes of aluminum veneer?

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: March 13, 2025 00:43:15

- Click:0

Aluminum veneerIt is a commonly used building material, and its manufacturing process is also one of the important factors affecting its quality and performance. Below is a detailed introduction to the production process and classification of aluminum veneer.

1、 The manufacturing process of aluminum veneer

The production process of aluminum veneer mainly includes the following steps:

1. Raw material preparation: Select high-quality aluminum alloy materials and perform cutting, polishing, and other treatments on them.

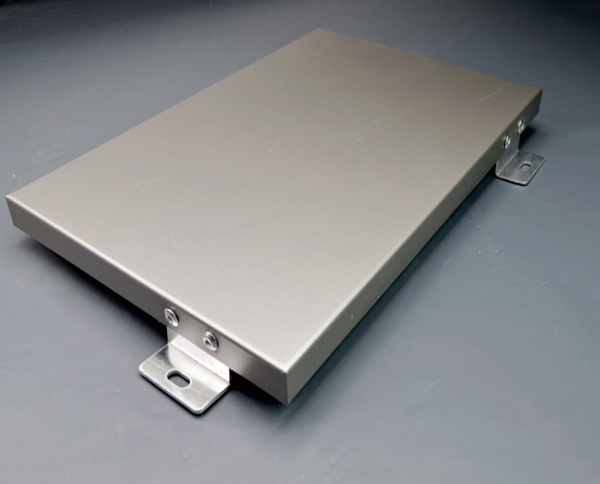

2. Forming processing: Raw materials are formed and processed according to design requirements, including stamping, bending, welding, and other methods.

3. Surface treatment: Surface treatment is carried out on the formed aluminum veneer, including anodizing, spraying, electrophoretic coating and other methods, to improve its corrosion resistance, hardness and aesthetics.

4. Installation and fixation: According to the design requirements, install and fix the aluminum veneer, including methods such as keel installation and hanging ear installation.

2、 Classification of Aluminum Veneers

According to different production processes and uses, aluminum veneer can be divided into the following categories:

1. Punched aluminum veneer: holes are formed on the aluminum veneer by stamping to increase its breathability and sound insulation effect.

2. embossed aluminum veneer: By embossing the aluminum veneer, its surface is presented with patterns or motifs to increase its decorative and aesthetic appeal.

3. Mirror finish aluminum veneer: Through special surface treatment techniques, the surface of the aluminum veneer presents a mirror effect, thereby increasing its reflectivity and glossiness.

4. Fluorocarbon aluminum veneer: Spray a layer of fluorocarbon coating on the surface of the aluminum veneer to improve its corrosion resistance and weather resistance.

The manufacturing process of aluminum veneer is one of the important factors affecting its quality and performance. In order to produce high-quality aluminum veneer, advanced manufacturing processes and equipment are required, and production and processing must be strictly carried out in accordance with design requirements. It is also necessary to choose different types of aluminum veneer for production and use according to different purposes and needs.

Customer service QQ

Customer service QQ