Industry information

Company News

- The Charm of Aluminum Veneer: The Perfect Fusion of Lightweight and Sturdy

- Aluminum veneer customization: an artistic journey to create personalized spaces

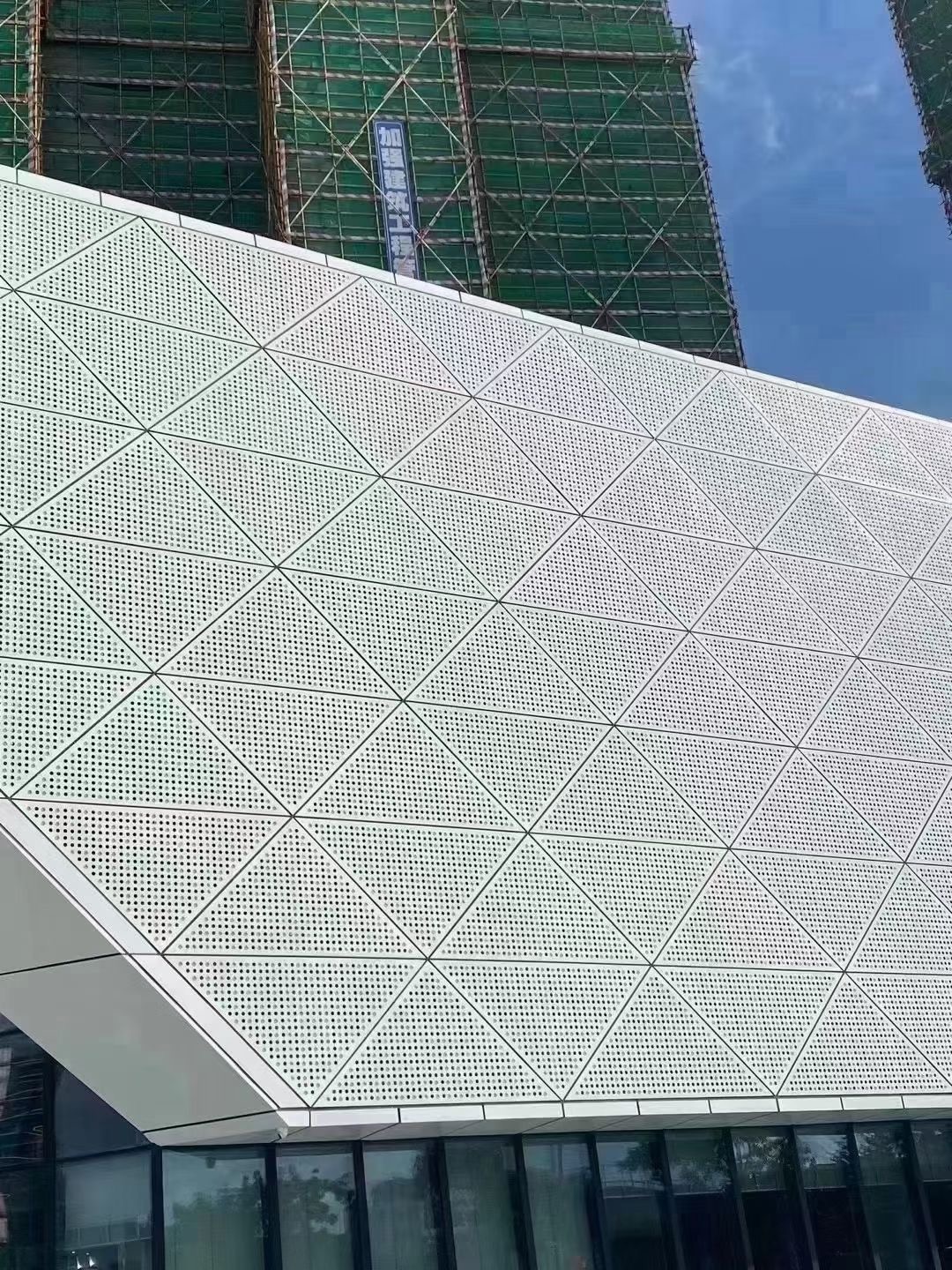

- Exploring perforated aluminum veneer: the beauty of metal, a new trend in architecture

- Fluorocarbon aluminum veneer: the hidden champion of fashionable architecture

- Carved aluminum veneer: unique design, interpreting modern aesthetics

Industry dynamics

- Curved surface and bending forming of curtain wall aluminum veneer

- How to purchase high-quality aluminum veneer at the most suitable price

- Punched aluminum veneer: a fashionable element in modern architecture

- Carved aluminum veneer: a fashionable choice for modern architecture

- Sharing of Maintenance Methods for Hotel Aluminum Ceiling

Frequently asked questions

- How to design customized aluminum veneer?

- How to use and maintain aluminum veneer reasonably?

- How to determine the quantity and size of customized aluminum veneer?

- How to use aluminum veneer for innovative design?

- How to improve the fire resistance of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Detailed description and optimization suggestions for customized aluminum veneer process flow

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: March 20, 2025 05:55:59

- Click:0

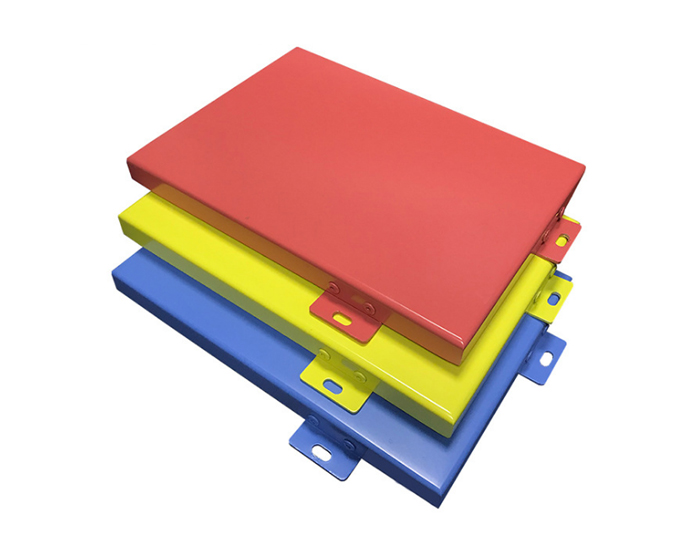

Aluminum veneerAs a new type of building material, it has the advantages of lightweight, high strength, corrosion resistance, and easy processing, and has been widely used in the field of architectural decoration. The process of customizing aluminum veneer is also an important issue that enterprises must face. Below, we will provide a detailed introduction to the customized process flow of aluminum veneer and related optimization suggestions.

1、 Process description

1. Raw material preparation

Before producing aluminum veneer, it is necessary to fully prepare the required raw materials, including aluminum alloy sheets, surface treatment agents, sealants, etc. At the same time, it is necessary to conduct quality testing and classification of raw materials to ensure the quality and performance of the products.

2. Design and manufacture molds

Before producing aluminum veneer, it is necessary to develop a product design plan and make corresponding molds according to the design plan. At the same time, it is necessary to conduct quality inspection and calibration of the mold to ensure the quality and accuracy of the product.

3. Rolling and cutting

During the rolling process, it is necessary to heat, roll, and cool the aluminum alloy sheet to achieve the desired size and shape. At the same time, it is necessary to cut and drill holes on the rolled aluminum veneer for subsequent processing and installation.

4. Surface treatment

During the surface treatment process, it is necessary to spray paint, anodize and other treatments on the aluminum veneer to improve its corrosion resistance and aesthetics. At the same time, it is necessary to test and adjust the surface treatment effect to ensure product quality and performance.

5. Sealing treatment

During the sealing process, it is necessary to fill and seal the aluminum veneer to improve its waterproof and durability. At the same time, it is necessary to test and adjust the sealing effect to ensure product quality and performance.

2、 Optimization suggestions

1. Introduce intelligent production lines

With the development of technology, intelligent production lines have become a trend in the future manufacturing industry. Aluminum veneer production enterprises can introduce intelligent production lines, improve production efficiency and product quality through technological means such as automation equipment and robots, and reduce production costs.

2. Improve the skill level of employees

Employees are one of the important resources of a company, and improving their skill level can enhance the competitiveness and profitability of the enterprise. Aluminum veneer production enterprises can improve the skill level of their employees through training and learning, enabling them to possess more professional knowledge and skills.

3. Strengthen brand building

Brand is one of the important assets of a company, which can enhance its visibility and reputation, and strengthen its market competitiveness. Aluminum veneer production enterprises can strengthen brand building, improve product quality and service level, and establish a good corporate image.

3、 Conclusion and Prospect

Through the detailed description of the above process flow and the introduction of optimization suggestions, it can be seen that the process flow of aluminum veneer customization is an important issue that enterprises must face. In the future, with the continuous advancement of technology and changes in market demand, the aluminum veneer industry will pay more attention to product quality and service level to meet the needs and expectations of consumers. At the same time, it is necessary to strengthen comparative research with other materials to provide consumers with more comprehensive and objective selection criteria. For enterprises, they should strengthen research and development innovation and technological upgrading, improve product quality and service level, in order to enhance their competitiveness and profitability. At the same time, it is necessary to strengthen cooperation and communication with other brands to jointly promote the development of the entire aluminum veneer industry.

Customer service QQ

Customer service QQ