Industry information

Company News

- Carved aluminum veneer, a small freshness in the aluminum industry

- Aluminum veneer customization, creating a new trend of personalized space

- Aluminum veneer customization, creating a new trend of personalized space

- Aluminum veneer customization, creating a new proposition for personalized space!

- Fluorocarbon aluminum veneer: not just aluminum, but also the beauty of architecture

Industry dynamics

- Punched aluminum veneer: the new darling of creative space, lightweight and fashionable!

- Future development direction of aluminum veneer prices

- Customize personalized aluminum veneer to create an exclusive aesthetic space

- Characteristics and Applicable Scenarios Analysis of Curved Aluminum Ceiling

- Carved aluminum veneer: the unique charm of architectural art

Frequently asked questions

- How to improve the fire resistance of aluminum veneer?

- How to identify the quality of aluminum veneer?

- How to use aluminum veneer for innovative design?

- How to determine the quantity and size of customized aluminum veneer?

- How to improve the insulation performance of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Aluminum veneer provides a variety of surface treatment options for building materials

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: February 26, 2025 19:26:59

- Click:0

Modern architecture requires multiple exterior treatment methods to meet the needs and requirements of different clients.Aluminum veneerAs a new type of building material, it has the advantages of lightweight, high strength, corrosion resistance, and easy processing, making it an ideal choice for building materials that can achieve various surface treatments. Below, we will provide a detailed introduction on how aluminum veneer offers multiple surface treatment options.

1、 Anodizing

Anodizing is a common surface treatment method that can result in a dark gray or black oxide film on the surface of aluminum veneer. This oxide film not only has excellent wear resistance and corrosion resistance, but also can increase the aesthetics and texture of aluminum veneer. After anodizing treatment, aluminum veneer can further improve its surface hardness and wear resistance, thereby extending its service life.

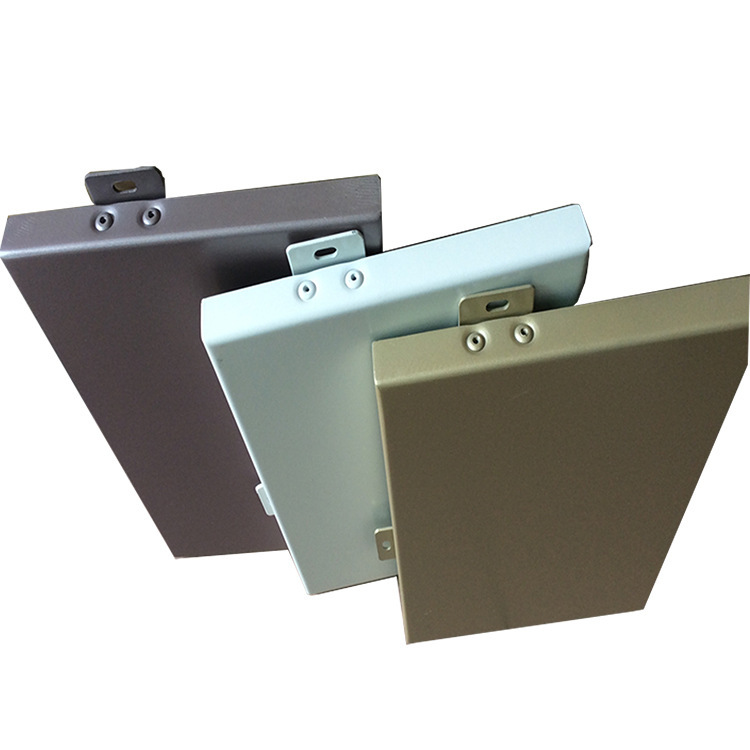

2、 Spray coating

Spray coating is another common surface treatment method that can create various colors and patterns on the surface of aluminum veneer. By spraying treatment, the surface of aluminum veneer can present different textures and glossiness, thereby enhancing its decorative effect. For example, sandblasting, wire drawing and other processing methods can be used to increase the roughness and texture of aluminum veneer, thereby reducing light reflection and refraction; Or use polyurethane foam and other materials to fill and seal the aluminum veneer, so as to further improve its beauty and texture.

3、 Fluorocarbon coating

Fluorocarbon coating is a high-end surface treatment method that can give aluminum veneer a metallic texture and glossiness. Fluorocarbon coatings have excellent weather resistance and corrosion resistance, and can maintain stable color and appearance in outdoor environments for a long time. Fluorocarbon coatings can also increase the hardness and wear resistance of aluminum veneers, thereby extending their service life.

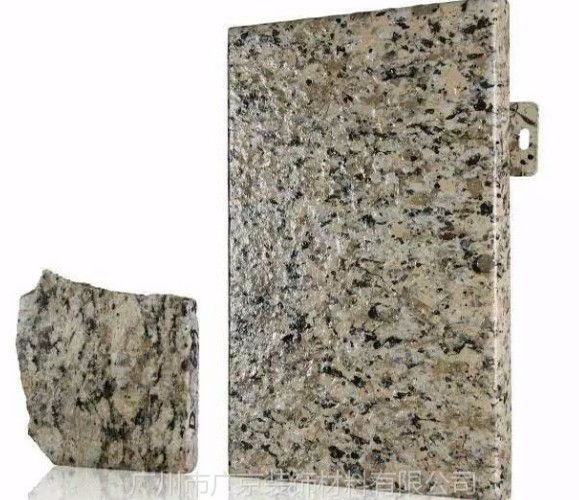

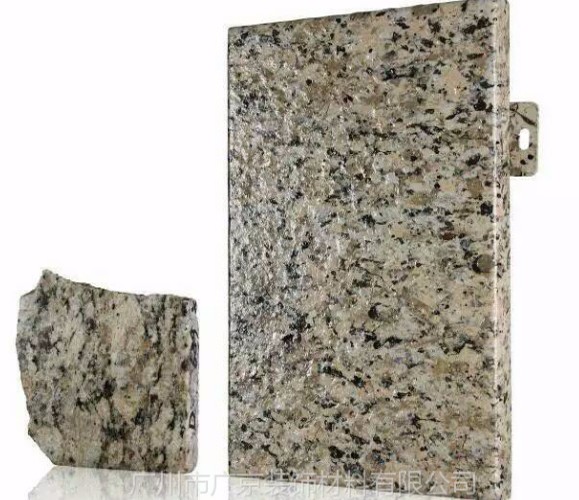

4、 Printing patterns

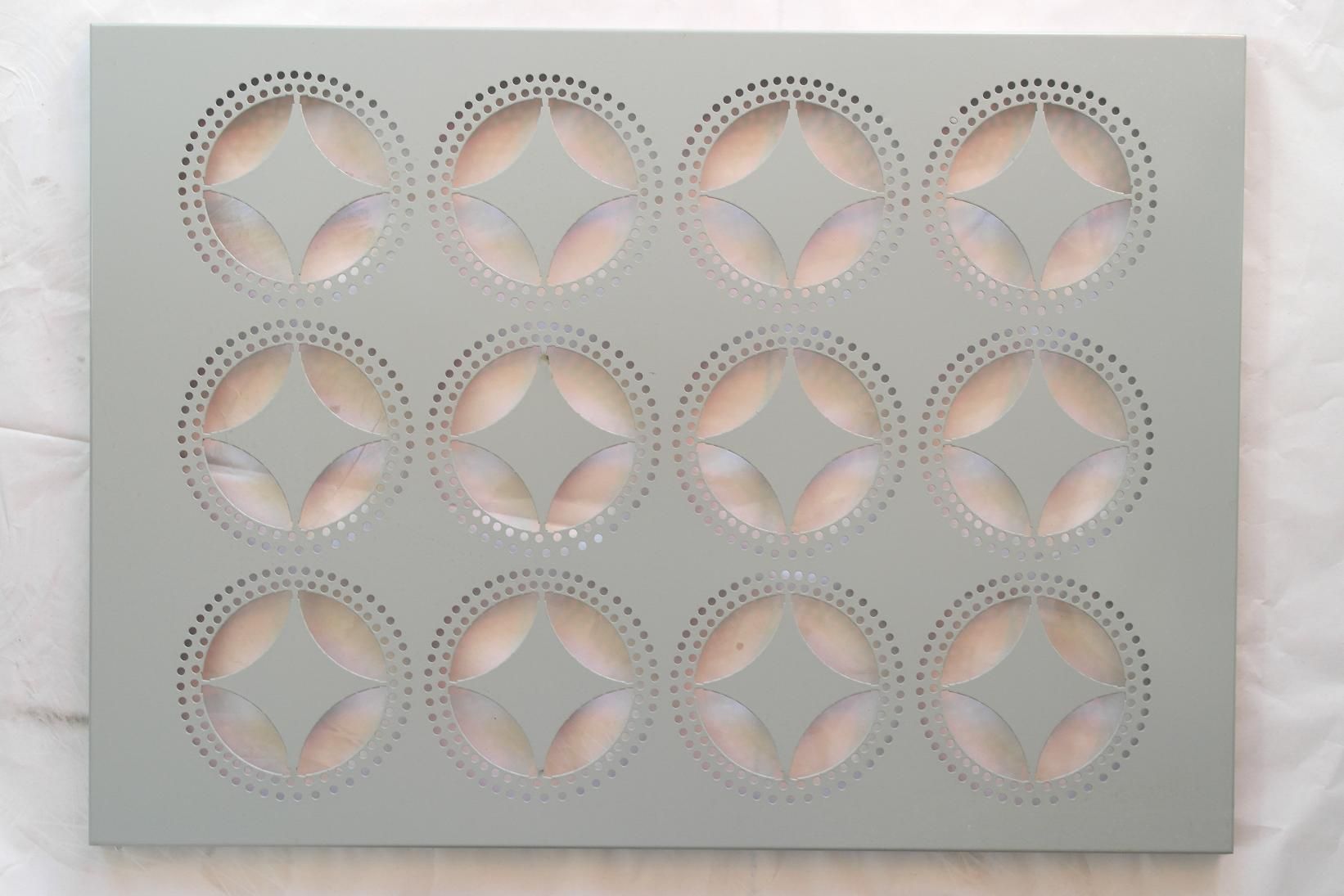

Printing patterns is a unique surface treatment method that can print various patterns and text onto the surface of aluminum veneer. Through printing processing, the surface of aluminum veneer can present a richer visual effect, thereby enhancing its decorative effect. For example, various patterns and texts can be printed onto aluminum veneers using methods such as hot stamping and heat transfer printing.

5、 Apply film

Film sticking is a simple surface treatment method that can create various colors and patterns on the surface of aluminum veneer. By applying film treatment, the surface of aluminum veneer can present a richer visual effect, thereby enhancing its decorative effect. For example, PVC, PET and other materials can be used to make various colors and patterns of film, and it can be pasted on aluminum veneer.

By fully utilizing the unique material properties of aluminum veneer and appropriate surface treatment techniques, it is possible to provide multiple surface treatment options for aluminum veneer in architectural design. This approach not only improves the overall aesthetics and decorative value of the building, but also reduces maintenance costs and energy consumption, contributing to the sustainable development of society. If you are looking for a building material that can provide multiple decorative material options for your city's buildings or sites, then consider aluminum veneer as an excellent building material option.

Customer service QQ

Customer service QQ