Industry information

Company News

- Punched aluminum veneer: unlimited creativity, creating personalized space!

- Aluminum veneer: the 'invisible hero' of modern architecture

- Punched aluminum veneer: the finishing touch of architectural aesthetics

- Aluminum veneer: an elegant element in modern architecture

- Punched aluminum veneer: the fashionable choice for modern architecture?

Industry dynamics

- What is the compressive performance of aluminum veneer?

- Punched aluminum veneer: the new darling of creative space

- The Charm of Aluminum Veneer: The "Face saving Project" of Modern Architecture

- Punched aluminum veneer: a fashionable choice in modern architecture

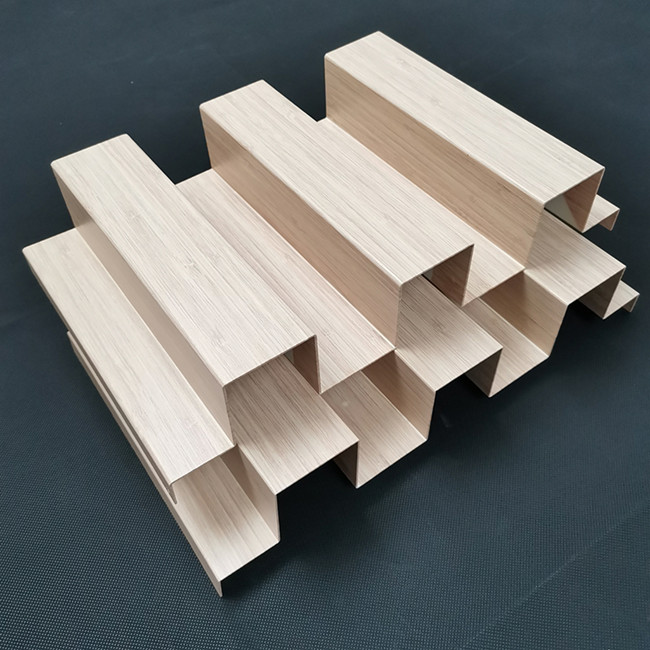

- Characteristics and Applications of Wood Grain Aluminum Veneer with Wrapped Columns

Frequently asked questions

- How to identify the quality of aluminum veneer?

- How to store and transport aluminum veneer?

- How to use aluminum veneer for innovative design?

- How to solve the environmental problems in the production process of aluminum veneer?

- How to improve the insulation performance of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Sharing of installation techniques for engineering fluorocarbon aluminum veneer

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: February 25, 2025 13:47:32

- Click:0

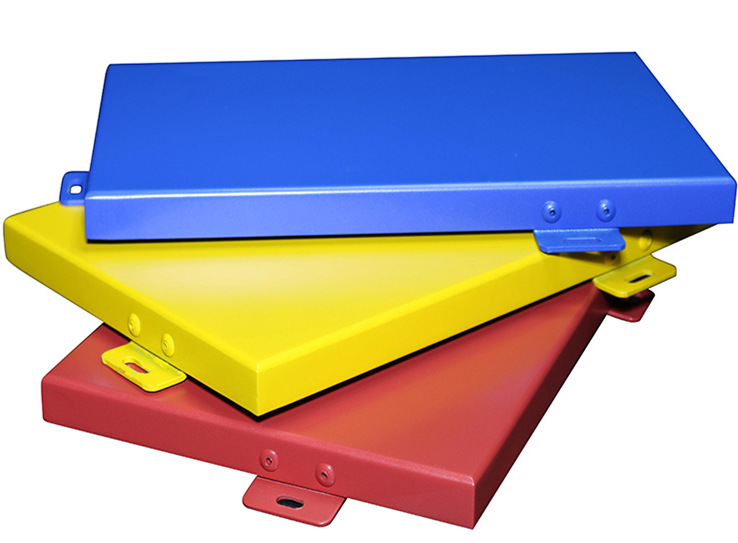

FluorocarbonAluminum veneerIt is a commonly used building material, and its installation techniques are crucial for ensuring project quality and effectiveness. Below, we will share some installation techniques for engineering fluorocarbon aluminum veneer.

1、 Preparation work

Before installing fluorocarbon aluminum veneer, some preparation work is required. Inspect the construction site to ensure that the ground is level and free of debris. Prepare the necessary tools and materials, such as drills, screwdrivers, corner codes, self tapping screws, etc. Measure and cut the fluorocarbon aluminum veneer to ensure its size and shape match the actual requirements.

2、 Install the keel frame

Before installing fluorocarbon aluminum veneer, it is necessary to install the keel frame first. The function of the keel frame is to support the fluorocarbon aluminum veneer, so that it can be stably fixed on the building. The installation of the keel frame should pay attention to the following points:

1. The material of the keel frame should meet the requirements and is generally made of materials such as aluminum alloy or steel.

The size of the keel frame should be adjusted according to the size of the fluorocarbon aluminum veneer to ensure its stability.

3. The installation position of the keel frame should be reasonable, generally fixed at the structural columns or beams of the building.

3、 Install fluorocarbon aluminum veneer

When installing fluorocarbon aluminum veneer, the following points should be noted:

The installation sequence of fluorocarbon aluminum veneer should be from bottom to top to avoid missing or incorrect installation.

When installing fluorocarbon aluminum veneer, it is necessary to use self tapping screws to fix the fluorocarbon aluminum veneer on the keel frame, and pay attention to the number and position of screws.

When installing fluorocarbon aluminum veneer, attention should be paid to its flatness and verticality, which can be measured and adjusted using a level.

4、 Closing work

After installing the fluorocarbon aluminum veneer, some finishing work is still needed. Clean and polish fluorocarbon aluminum veneer to remove surface dirt and scratches. Punching and slotting treatment should be carried out on fluorocarbon aluminum veneer to facilitate the installation of electrical wiring and other facilities in the future. Fluorocarbon aluminum veneer needs to be coated or sprayed to enhance its durability and aesthetics.

The above is a sharing of installation techniques for engineering fluorocarbon aluminum veneer. The correct installation method can ensure the quality and effectiveness of fluorocarbon aluminum veneer, while also improving construction efficiency and safety.

Customer service QQ

Customer service QQ