Corporate News

Company News

- Aluminum veneer customization, artistic interpretation of personalized space

- 2. Carved aluminum veneer, an artistic treasure in the aluminum world. 3 Carved Aluminum Veneer: Modern Architecture

- Exquisite punched aluminum veneer: the new favorite of architectural art

- Fluorocarbon aluminum veneer: the new darling of the construction industry, revealing its unique charm!

- Aluminum veneer: the beauty of architecture, details can be seen in the real chapter

Industry dynamics

- 2. New trend of aluminum veneer: carved aesthetics, taste life. 3 Carved aluminum veneer, home decor

- Carved Aluminum Veneer: The Gorgeous' Clothing 'of Modern Architecture

- Design inspiration for irregular fluorocarbon aluminum veneer in interior decoration

- Aluminum veneer manufacturer's production process publicly disclosed

- Fluorocarbon aluminum veneer: a perfect combination of fashion and durability

Frequently asked questions

- How to improve the insulation performance of aluminum veneer?

- How to store and transport aluminum veneer?

- How to solve the environmental problems in the production process of aluminum veneer?

- How to identify the quality of aluminum veneer?

- How to use aluminum veneer for innovative design?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

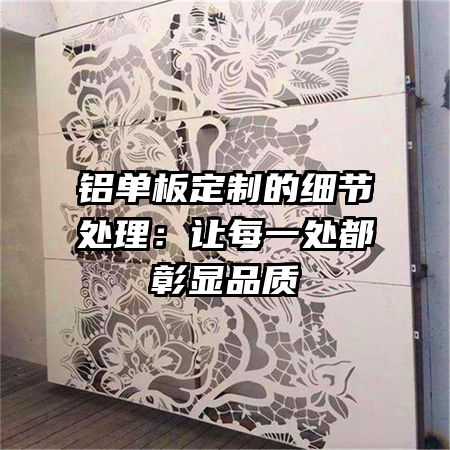

Detail processing of customized aluminum veneer: showcasing quality in every aspect

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: February 23, 2025 19:01:48

- Click:0

Aluminum veneerCustomized detail processing: making every aspect showcase quality

With the increasing demand for the aesthetic appearance of buildings, aluminum veneer has become one of the most common building materials in modern architecture. For customized aluminum veneer, the quality of detail processing directly determines the final quality and aesthetics of the aluminum veneer. This article will elaborate on the details of aluminum veneer customization from four aspects, so that every aspect can showcase quality.

1、 Design and Planning Stage

In the planning stage of customized design for aluminum veneer, the following aspects need to be noted:

1. Complete design drawings

The customized design drawings for aluminum veneer should be very clear and explicit, including the dimensions and positions of each component, as well as the connection and installation methods. Only in this way can manufacturers accurately manufacture aluminum veneer according to the drawings.

2. Reasonable structural design

In addition to size and position, the structural design of aluminum veneer is also crucial. If the design structure is not reasonable, it may lead to problems such as cracking and deformation of aluminum veneer after long-term use. Therefore, when designing aluminum veneer structures, it is necessary to consider the building's usage environment and external factors, and adopt reasonable reinforcement measures to ensure its stability and durability.

3. Appropriate decoration methods

The decoration method of aluminum veneer has a significant impact on the final effect. Different decoration methods can affect the hardness, texture, and durability of aluminum veneer. Therefore, it is necessary to select suitable decorative materials and techniques, and conduct detailed experiments and tests to ensure that the final effect meets the design requirements.

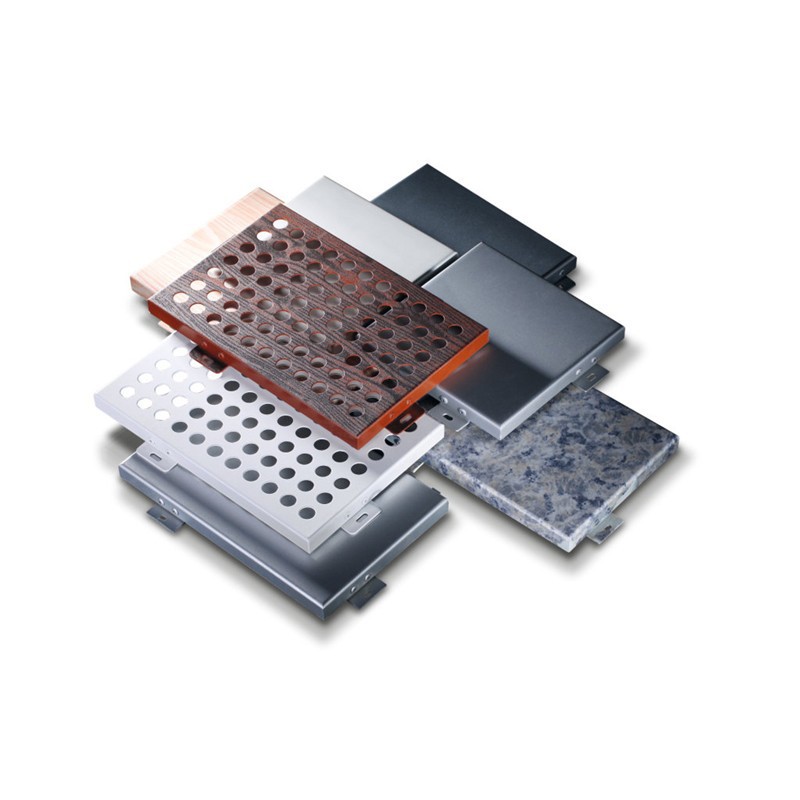

2、 Material selection stage

In the selection stage of aluminum veneer materials, the following aspects need to be noted:

1. Board quality

The quality of aluminum veneer is mainly affected by factors such as the manufacturer's process technology and material selection quality. Therefore, choosing the appropriate manufacturer is also a key step in ensuring the quality of aluminum veneer. In addition, the performance indicators such as thickness and hardness of the board also need to be selected according to the specific usage environment.

2. Surface treatment

The surface treatment of aluminum veneer can be carried out through oxidation, spraying, and electrophoresis. The quality of surface treatment also has a significant impact on the final effect. Suitable surface treatment methods and processes need to be selected based on factors such as the building's usage environment, climate conditions, and style requirements.

3. Accessory selection

The selection of accessories also affects the quality of aluminum veneer. Generally speaking, aluminum veneer accessories should be made of the same material and match the structure of the aluminum veneer. In addition, the quality of the accessories should also be guaranteed to ensure the overall quality of the aluminum veneer.

3、 Production and manufacturing stage

In the production and manufacturing process of aluminum veneer, the following aspects need to be noted:

1. Processing accuracy

Processing accuracy is a key factor in ensuring the precise size and shape of aluminum veneer. During the processing, it is necessary to ensure the accuracy of the machine equipment and the skill level of the operators. In addition, attention should be paid to preventing scratches, deformations, and other issues during the processing.

2. Spray coating process

Spraying is one of the important processes for surface treatment of aluminum veneer. When spraying, attention should be paid to the selection and dilution ratio of the coating to ensure that the quality and color of the coating meet the design requirements. In addition, attention should be paid to the influence of environmental factors such as temperature and humidity to ensure the spraying effect.

3. Quality control

Quality control is the last line of defense to ensure the quality of aluminum veneer. In the production process, it is necessary to establish a strict quality inspection system and archive the quality inspection records for easy traceability. Before leaving the factory, a comprehensive inspection and testing of all products is required to ensure that their quality meets the standards.

4、 Installation and construction phase

During the installation and construction phase of aluminum veneer, the following aspects should be noted:

1. Installation method

The installation method of aluminum veneer also has a significant impact on the final effect. Different building structures and materials require different installation methods. At the same time, during installation, factors such as the load-bearing capacity of supporting structures and materials, as well as safety issues, need to be considered.

2. Seam treatment

Joint treatment is also an important step in ensuring the aesthetic appearance and sealing of aluminum veneer. When processing seams, it is necessary to ensure the accuracy and sealing of the seams. If the joint is not handled properly, it may lead to problems such as water leakage and ingress.

3. Safety measures

Safety measures are important considerations in the installation and construction of aluminum veneer panels. During the installation and construction process, it is necessary to strictly comply with safety operation regulations and take necessary protective measures to ensure the safety of workers.

5、 Summary:

Details determine quality, and aluminum veneer customization is no exception. From design planning to production and manufacturing, to installation and construction, every step needs to be carefully handled. Only in this way can the quality and aesthetics of aluminum veneer be guaranteed.

Customer service QQ

Customer service QQ