Industry information

Company News

- Aluminum veneer customization: an artistic journey to create personalized spaces

- The market trend of customized aluminum veneer: constantly expanding consumer demand

- Aluminum veneer customization, creating personalized space and new fashion

- Carved aluminum veneer: a magnificent choice for modern architecture

- Ancient charm and modern style, carved aluminum veneer: an art that blends modernity and tradition

Industry dynamics

- The Fashion Journey of Punched Aluminum Veneer: Exploring the Beauty of Architecture

- The application value of arc carved aluminum veneer in indoor decoration

- Ancient charm and modern style, an artistic journey of carved aluminum veneer

- Fluorocarbon aluminum veneer: a shining pearl of modern architecture

- Aluminum veneer customization, creating a new trend of exclusive style

Frequently asked questions

- How to distinguish the quality of aluminum veneer?

- How to improve the fire resistance of aluminum veneer?

- How to design customized aluminum veneer?

- How to identify the quality of aluminum veneer?

- How to store and transport aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

How to improve the corrosion resistance of aluminum veneer?

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: March 1, 2025 06:47:26

- Click:0

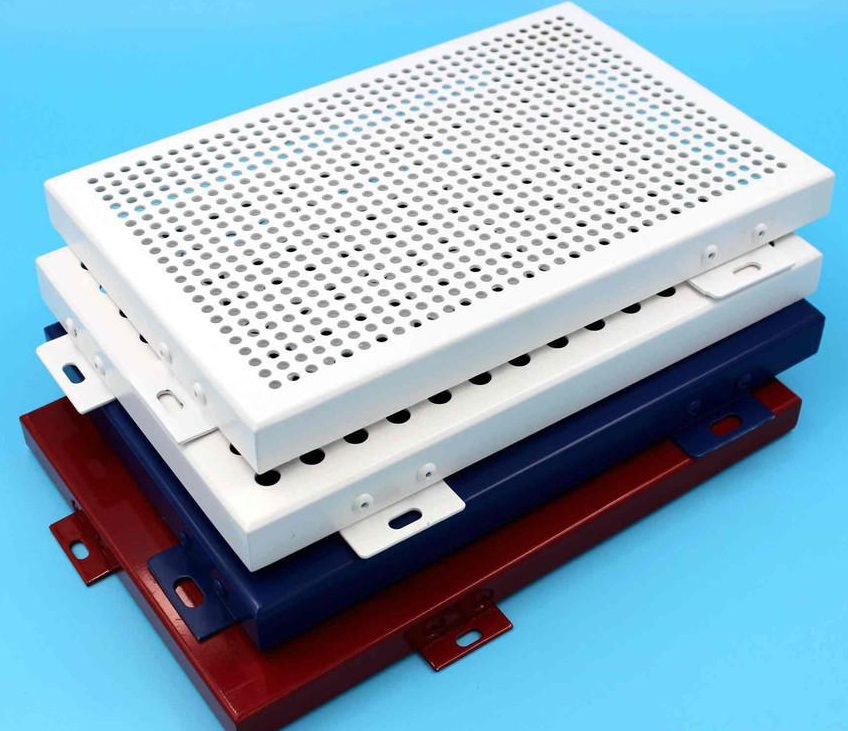

Aluminum veneerIt is a common building material, and its corrosion resistance is one of the important factors affecting its service life and aesthetics. In order to improve the corrosion resistance of aluminum veneer, it is necessary to start from multiple aspects, such as optimizing material selection, strengthening surface treatment, and adding anti-corrosion coatings. Below, we will provide a detailed introduction on how to improve the corrosion resistance of aluminum veneer.

1、 Optimize material selection

When improving the corrosion resistance of aluminum veneer, the first step is to optimize material selection. High quality anti-corrosion materials have high corrosion resistance and weather resistance, which can reduce the impact on the environment. Attention should also be paid to the renewability and recycling of materials to reduce resource waste and environmental pollution.

2、 Strengthen surface treatment

When improving the corrosion resistance of aluminum veneer, it is also necessary to strengthen surface treatment. Different surface treatment methods, such as spraying and roll forming, can be used to enhance the aesthetic and decorative appeal of aluminum veneer. Attention should also be paid to the flatness and smoothness of the surface to reduce air resistance and friction, and lower the corrosion risk of aluminum veneer.

3、 Add anti-corrosion coating

When improving the corrosion resistance of aluminum veneer, it is also necessary to add anti-corrosion coatings. This can be achieved by adding anti-corrosion coatings or increasing the thickness of anti-corrosion coatings. Anti corrosion coatings can be made of materials such as epoxy resin and polyurethane, and the thickness of the anti-corrosion coating can be adjusted according to the actual situation. By adding anti-corrosion coatings, aluminum veneers can be effectively protected from oxidation, corrosion, and other forms of damage.

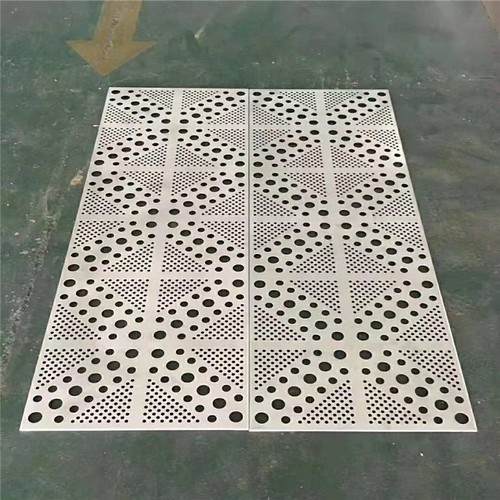

4、 Strengthen environmental management

When improving the corrosion resistance of aluminum veneer, it is also necessary to strengthen environmental management. By controlling pollution sources, regular cleaning and maintenance, etc., the impact of external environment on aluminum veneer can be reduced. We should also pay attention to the cultivation of environmental awareness and strengthen employee training to enhance their environmental awareness and sense of responsibility.

5、 Strengthen product testing

When improving the corrosion resistance of aluminum veneer, it is also necessary to strengthen product testing. Comprehensive quality inspection and evaluation of aluminum veneer can be carried out by establishing a sound quality inspection system and testing standards. Timely identify and resolve product quality issues to ensure product safety and reliability.

Improving the corrosion resistance of aluminum veneer requires multiple aspects, including optimizing material selection, strengthening surface treatment, adding anti-corrosion coatings, enhancing environmental management, and strengthening product testing. Only by comprehensively strengthening these aspects of work can we truly achieve the improvement of corrosion resistance and sustainable development of aluminum veneer.

Customer service QQ

Customer service QQ