Industry information

Company News

- Aluminum veneer customization, creating personalized space and new fashion

- Aluminum veneer customization, creating the art of personalized space

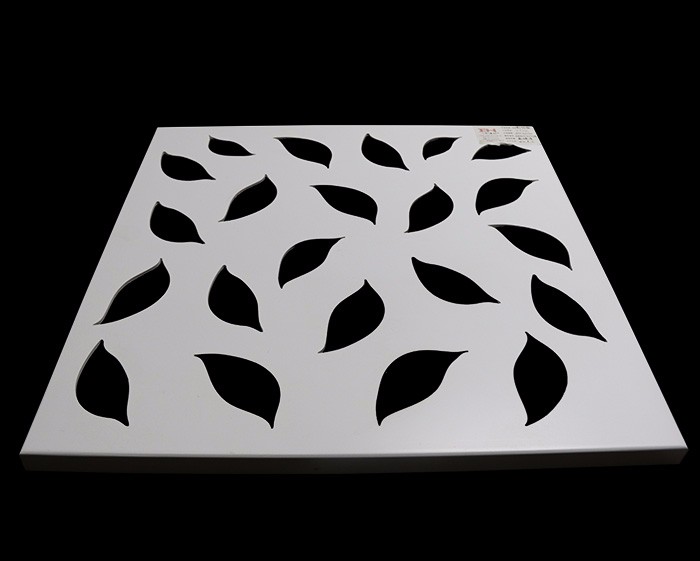

- Exploring perforated aluminum veneer: the beauty of metal, a new trend in architecture

- Fluorocarbon aluminum veneer: the new darling of architectural beauty

- Aluminum veneer: the fashionable outerwear of modern architecture

Industry dynamics

- Detailed explanation of the production process of aluminum veneer manufacturers

- Punched aluminum veneer: the new favorite of modern architectural aesthetics

- Aluminum veneer customization, creating personalized space and new fashion

- Customized aluminum veneer, creating a new proposition for personalized space

- Fluorocarbon aluminum veneer: the new favorite of modern architecture, a new chapter in texture life

Frequently asked questions

- How to determine the quantity and size of customized aluminum veneer?

- How to improve the fire resistance of aluminum veneer?

- How to solve the environmental problems in the production process of aluminum veneer?

- How to distinguish the quality of aluminum veneer?

- How to store and transport aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

How to improve the UV resistance of aluminum veneer?

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: 2022-03-01 07:09:24

- Click:0

Aluminum veneerIt is a common building material with advantages such as lightweight, high strength, thermal insulation, and fire resistance. With the acceleration of urbanization and the impact of climate change, ultraviolet radiation is becoming increasingly intense, posing certain challenges to aluminum veneer. How to improve the UV resistance of aluminum veneer has become one of the current research focuses. This article will provide a detailed introduction to several methods for improving the UV resistance of aluminum veneer.

1. Adopt anodizing treatment

Anodizing treatment is a commonly used surface treatment method that can form a dense oxide film on the surface of aluminum veneer. This oxide film has high hardness and wear resistance, and can effectively resist the damage of ultraviolet rays. The oxide film can also absorb some ultraviolet radiation, thereby reducing its damage to aluminum veneer.

1. Add anti UV agent

In the production process of aluminum veneer, some UV resistant agents such as fluorocarbon resin can be added. These additives can form a thin film on the surface of aluminum veneer, effectively preventing UV damage. These additives can also improve the weather resistance and corrosion resistance of aluminum veneer, making it more durable.

1. Use coatings of different colors

Different colored coatings also have an impact on the ability to resist ultraviolet radiation. Generally speaking, dark coatings can better absorb ultraviolet rays, thereby reducing their damage to aluminum veneers. During the production process, darker colors can be chosen to enhance the UV resistance of aluminum veneer.

1. Control the temperature of the production environment

The temperature of the production environment can also affect the UV resistance of aluminum veneer. Generally speaking, the higher the temperature, the thinner the oxide film on the surface of aluminum veneer, making it more susceptible to ultraviolet radiation. During the production process, it is necessary to control the temperature well to avoid situations where it is too high or too low.

Improving the UV resistance of aluminum veneer is one of the current research focuses. By adopting anodizing treatment, adding anti UV agents, using different colored coatings, and controlling the production environment temperature, the anti UV ability of aluminum veneer can be effectively improved and its service life can be extended.

Customer service QQ

Customer service QQ