Industry information

Company News

- Aluminum veneer is not just a synonym for building materials

- Punched aluminum veneer: a fashionable choice for modern architecture, revealing its charm!

- Aluminum veneer customization, creating an exclusive aesthetic for your space

- Fluorocarbon aluminum veneer: the fashionable "coat" of modern architecture

- Punched aluminum veneer: the artistic new favorite of the aluminum world

Industry dynamics

- Aluminum veneer customization, creating a new trend of personalized space!

- Aluminum veneer customization, creating a new trend of personalized space

- Aluminum veneer: the new darling of industrial aesthetics, revealing the secrets behind it!

- Production process and technical requirements of aluminum veneer

- Fluorocarbon aluminum veneer: the new favorite of modern architecture, a new chapter in texture life

Frequently asked questions

- How to distinguish the quality of aluminum veneer?

- How to store and transport aluminum veneer?

- How to improve the fire resistance of aluminum veneer?

- How to identify the quality of aluminum veneer?

- How to design customized aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Production process and quality control of irregular fluorocarbon aluminum veneer

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: March 10, 2025 01:15:06

- Click:0

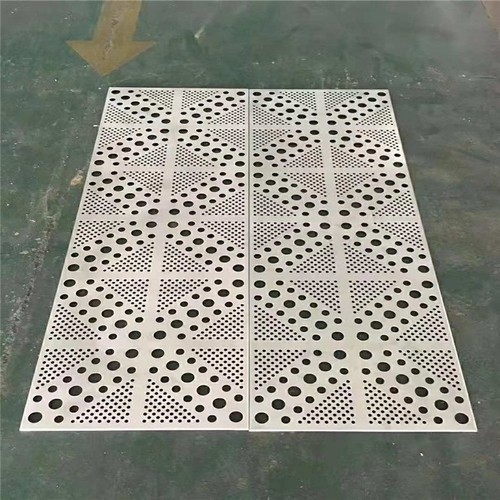

Alien fluorocarbonAluminum veneerAs a high-end decorative material, its production process and quality control are crucial to ensuring the quality and effectiveness of the product. Here are some contents about the production process and quality control of irregular fluorocarbon aluminum veneer.

1、 Production process

1. Raw material preparation: High quality aluminum alloy materials are selected as the basis, and cutting, stamping, and other processing are carried out according to design requirements to obtain the required shaped fluorocarbon aluminum veneer.

2. Surface treatment: Anodize the irregular fluorocarbon aluminum veneer to form a hard oxide film on its surface, improving its wear resistance and corrosion resistance.

3. Spray treatment: Through spray treatment, the surface of irregular fluorocarbon aluminum veneer can present different colors and texture effects, enhancing its decorative and artistic qualities.

4. Veneer treatment: Different materials of boards can be laminated onto irregular fluorocarbon aluminum veneers through veneer treatment, increasing their decorative and practical value.

2、 Quality control

1. Raw material inspection: Strictly inspect the incoming raw materials to ensure that their quality meets the requirements.

2. Production process control: Strictly control each link in the production process to ensure that the dimensional accuracy and surface smoothness of the product meet the standards.

3. Testing and Inspection: Conduct comprehensive testing and inspection of the produced irregular fluorocarbon aluminum veneer, including testing of size, hardness, strength, appearance, etc., to ensure that the product quality meets the standards.

4. Packaging and transportation: Packaging and transportation of finished products to ensure that they are not damaged or deformed during transportation.

3、 Quality Assurance

1. Product quality assurance: The company strictly manages in accordance with the requirements of the ISO9001 international quality management system to ensure that product quality meets national standards and customer requirements.

2. After sales service guarantee: The company provides a comprehensive after-sales service system, offering timely technical support and solutions to ensure customer satisfaction.

3. Continuous improvement: The company continuously optimizes production processes and technologies, improves product quality and efficiency, and meets the ever-changing needs of customers.

The production process and quality control of irregular fluorocarbon aluminum veneer are crucial for ensuring the quality and effectiveness of the product. In the future, with the continuous improvement of people's requirements for indoor environmental quality and the continuous advancement of technology, irregular fluorocarbon aluminum veneer will be more widely used and developed.

Customer service QQ

Customer service QQ