Industry information

Company News

- Ancient charm and new materials, carved aluminum veneer: not just decoration, but also art

- The Fashion Charm of Aluminum Veneer: Creating a New Choice for Personalized Space

- Aluminum veneer: the fashionable choice for modern architecture

- Customized aluminum veneer, creating an artistic journey of personalized space

- Aluminum veneer: a perfect combination of architectural aesthetics and practicality

Industry dynamics

- Personalized customized aluminum veneer, creating an exclusive aesthetic space

- Is the strength of aluminum veneer sufficient to meet the requirements of architectural design?

- Fluorocarbon aluminum veneer: the fashionable new favorite of future architecture

- Quality assurance for customized aluminum veneer: strict quality standards to create excellent quality

- Carved Aluminum Veneer: A New Chapter in Aluminum Art

Frequently asked questions

- How to distinguish the quality of aluminum veneer?

- How to store and transport aluminum veneer?

- How to solve the environmental problems in the production process of aluminum veneer?

- How to improve the fire resistance of aluminum veneer?

- How to determine the quantity and size of customized aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

The production process and construction techniques of 2.5mm curved aluminum veneer

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: March 10, 2025 09:58:54

- Click:0

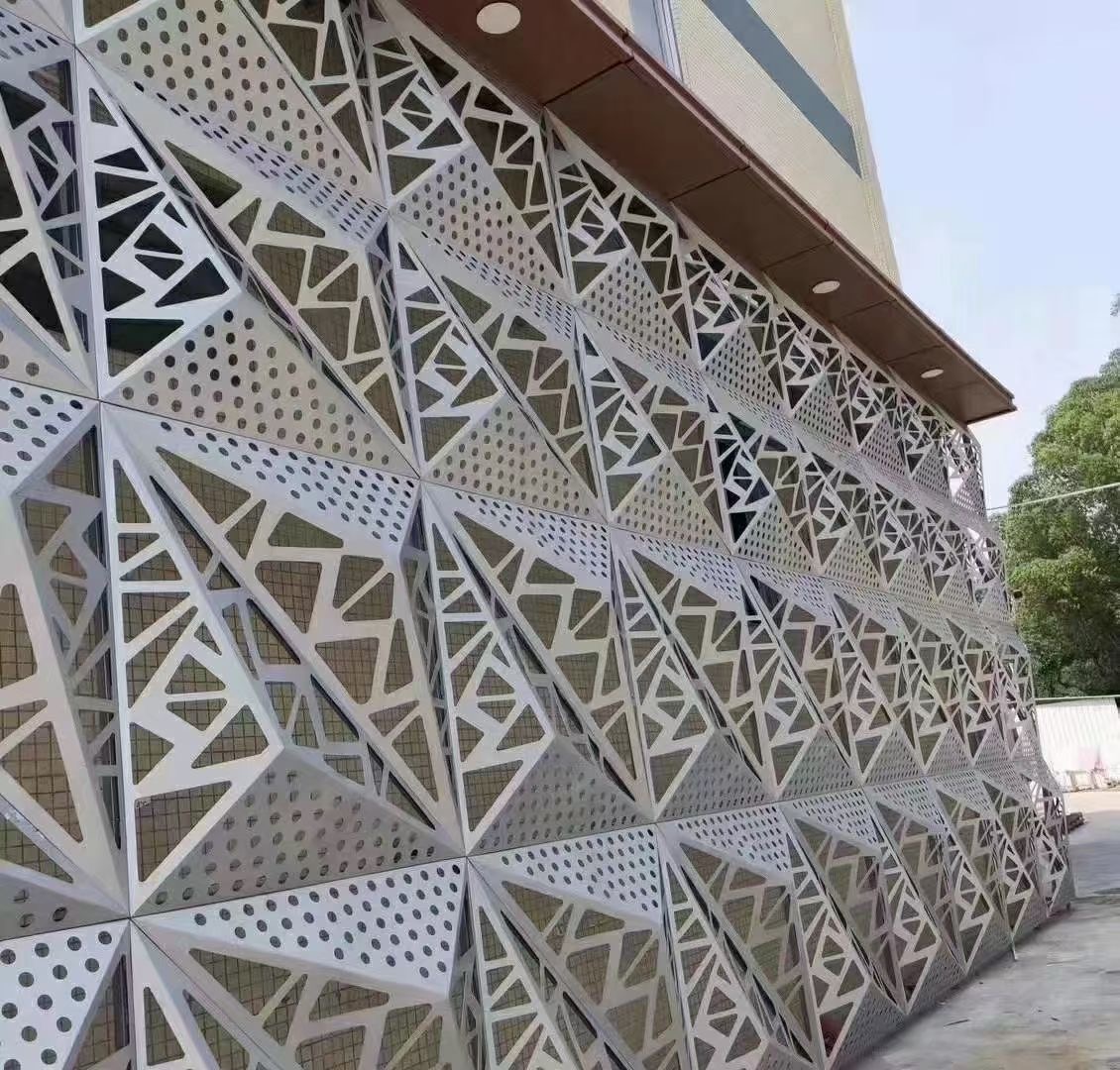

Arc 2.5mmAluminum veneerIt is a new type of building material, and the production process and construction techniques are crucial to ensuring the quality and effectiveness of the product. The following are some contents about the production process and construction techniques of 2.5mm curved aluminum veneer.

1、 Production process

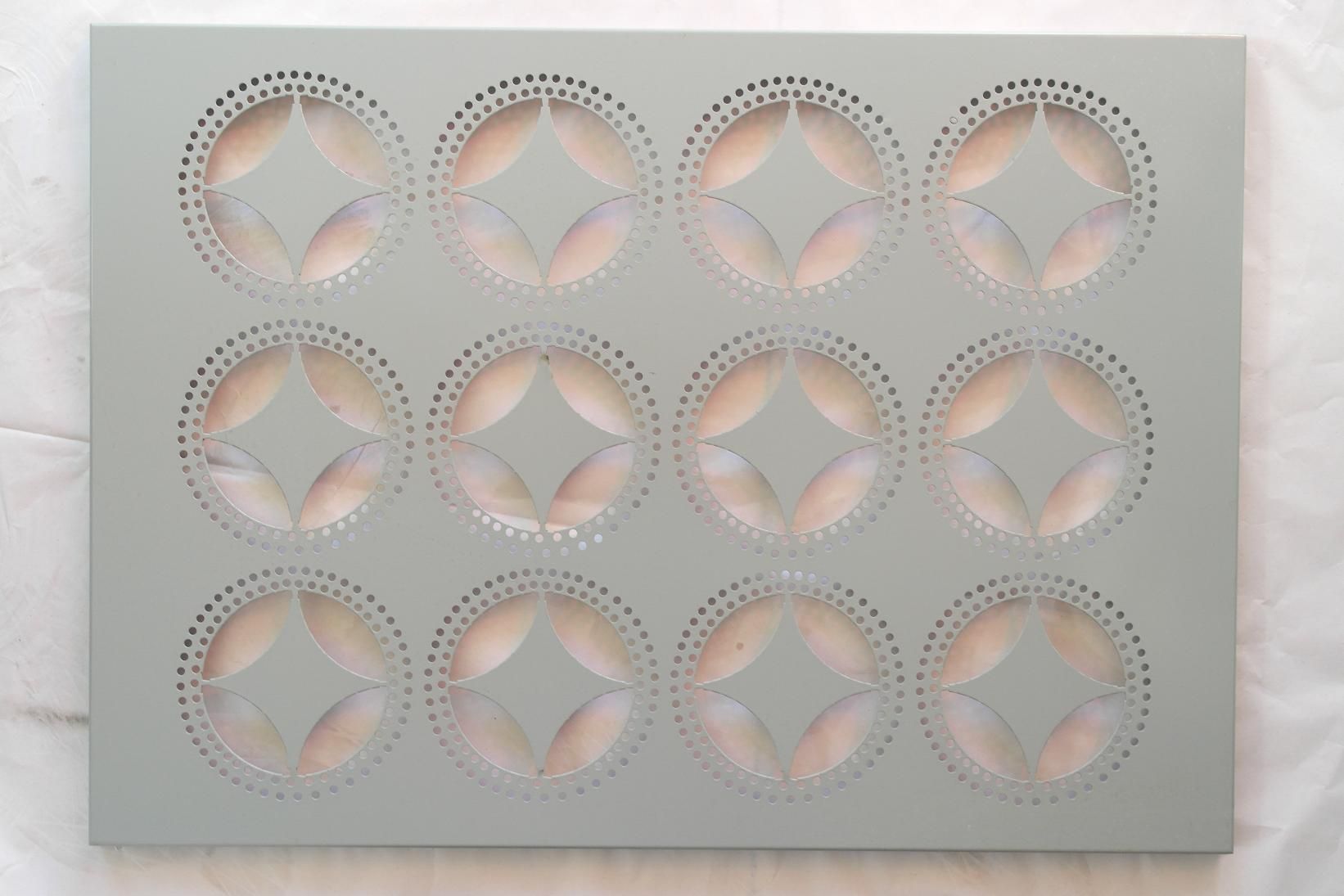

1. Cutting: Cut the aluminum alloy sheet into the required size and shape according to the design requirements.

2. Bending: Bend the cut sheet metal to form the desired curvature.

3. Drilling: Drill holes on the board according to design requirements for subsequent installation.

4. Surface treatment: Surface treatment of the board, such as spraying, anodizing, etc., to increase the aesthetics and corrosion resistance of the product.

5. Inspection: Conduct quality inspection on the completed product to ensure that it meets the design requirements and standards.

2、 Construction Techniques

1. Accurate measurement: Before construction, the required installation position and size should be accurately measured to ensure the accuracy and precision of the installation.

2. Fixed firmly: When installing a 2.5mm curved aluminum veneer, a reliable fixing method should be used to ensure its firmness and stability.

3. Tight joints: When connecting 2.5mm aluminum veneer with circular arcs, attention should be paid to the tightness and flatness of the joints to avoid water leakage or excessive gaps.

4. Protection measures: During the construction process, attention should be paid to protecting the installed 2.5mm aluminum veneer with circular arcs to avoid damage or pollution.

3、 Precautions

1. Choose high-quality materials: When making 2.5mm curved aluminum veneer, high-quality aluminum alloy sheets and coatings should be used as raw materials to ensure the quality and performance of the product.

2. Strictly follow the design requirements for construction: During the construction process, operations should be carried out strictly in accordance with the design requirements to avoid errors or non conformities.

3. Pay attention to safety: During the construction process, safety should be taken into account to avoid accidents or personal injuries.

4、 Application prospects

With the development of the construction industry, 2.5mm curved aluminum veneer will be more widely used and developed. It will become an indispensable part of architectural decoration, bringing a better experience and feeling to people's lives and work. We will continue to adhere to the business philosophy of "quality first, customer first", continuously improve our technology and service level, and provide customers with higher quality products and services.

Customer service QQ

Customer service QQ