Industry information

Company News

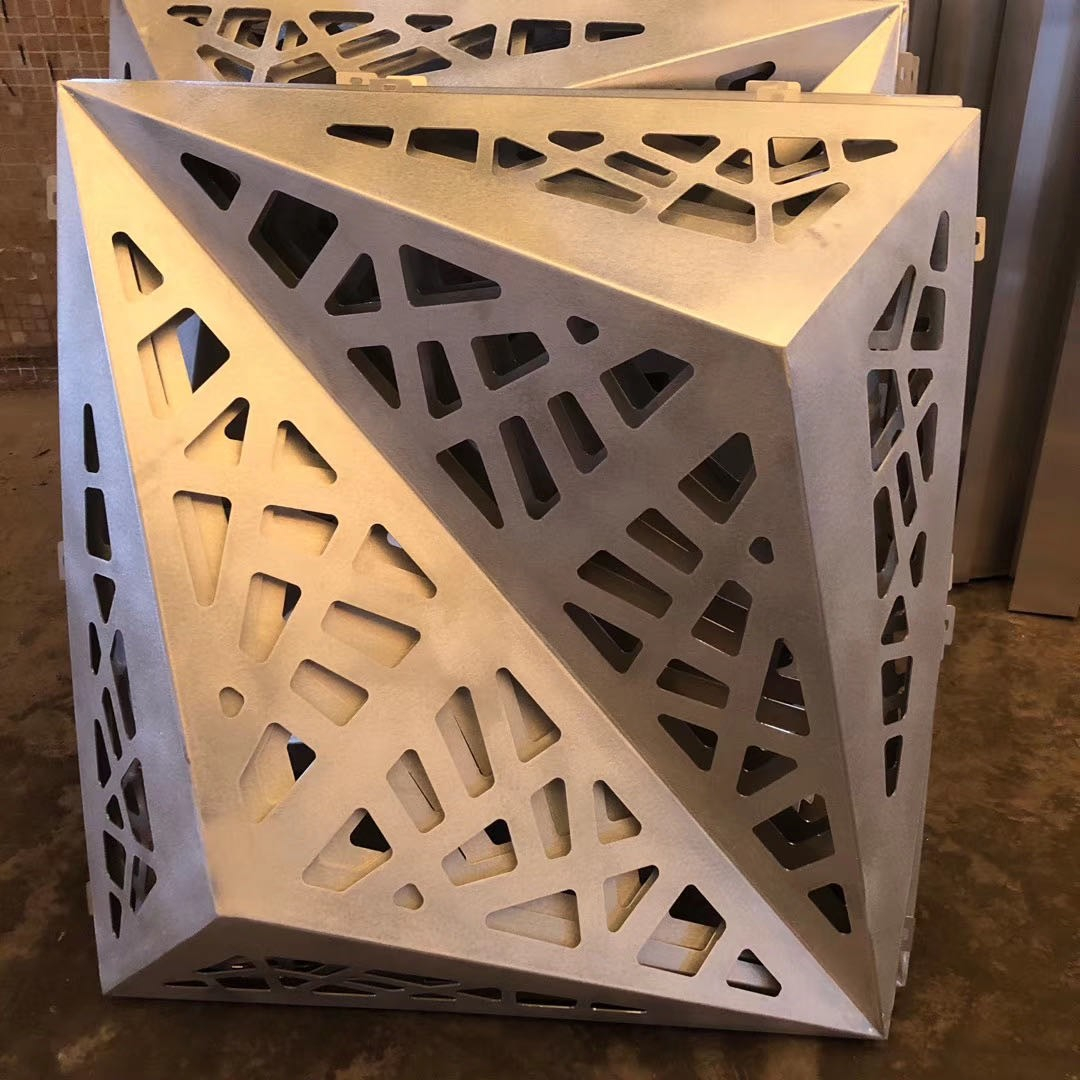

- Punched aluminum veneer, the finishing touch of fashionable building materials

- Detail processing of customized aluminum veneer: showcasing quality in every aspect

- New rising star in aluminum veneer reveals the unique charm of punched aluminum veneer!

- Ancient charm and new materials, carved aluminum veneer: not just decoration, but also art

- Fluorocarbon aluminum veneer: the fashionable "coat" of modern architecture

Industry dynamics

- Exquisite fluorocarbon curved aluminum veneer showcases architectural charm

- Key points for customized construction of aluminum veneer

- Aluminum veneer: the new favorite of modern architecture, environmentally friendly and fashionable!

- Aluminum veneer punching, creating a new trend of personalized space

- Economic analysis of aluminum veneer price

Frequently asked questions

- How to distinguish the quality of aluminum veneer?

- How to identify the quality of aluminum veneer?

- How to use and maintain aluminum veneer reasonably?

- How to solve the environmental problems in the production process of aluminum veneer?

- How to use aluminum veneer for innovative design?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Production process of high-quality roller coated ceiling aluminum veneer

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: February 26, 2025 01:57:23

- Click:0

Roller coated ceilingAluminum veneerIt is a high-quality building material with advantages such as beauty, durability, and easy installation. The quality of its production process directly affects the quality and service life of the product. Let's take a detailed look at the production process of high-quality roller coated ceiling aluminum veneer.

1、 Selection of raw materials

High quality roller coated ceiling aluminum veneer first requires the use of high-quality raw materials, such as 1100, 3003, 5050 aluminum alloy sheets, as well as fluorocarbon paint and other coatings. These raw materials need to undergo strict screening and testing to ensure that they meet national standards and product quality requirements.

2、 Pre processing

Before roller coating, it is necessary to perform surface pre-treatment on the aluminum veneer, including removing impurities such as oxide layer, oil stains, and dust. This step is very important because without pre-treatment, it will affect the adhesion and durability of the coating.

3、 Roll coating process

Roll coating is one of the main production processes for roll coated ceiling aluminum veneer. Firstly, place the aluminum veneer on the roller, and then evenly cover the coating on the aluminum veneer through the pressure of the roller. During the rolling coating process, attention should be paid to controlling the thickness and uniformity of the coating to ensure the quality of the coating. Attention should also be paid to factors such as viscosity and temperature of the coating to ensure its adhesion and durability.

4、 Drying process

After the rolling coating is completed, the aluminum veneer needs to be dried. The purpose of drying is to evaporate excess moisture to prevent problems such as blistering and cracking of the coating. Generally speaking, the drying temperature is around 40 ° C and the time is about 24 hours. During the drying process, it is also necessary to pay attention to factors such as ventilation and humidity to ensure the drying effect.

5、 Spray coating process

For some aluminum veneers with special requirements, spraying technology is also required. Spraying is a process of applying fluorocarbon paint and other coatings onto the surface of aluminum veneer. The advantages of spraying are bright colors, high glossiness, and strong wear resistance. However, the spraying process is also quite complex and requires a certain level of technical expertise and experience.

6、 Post processing

It is also necessary to perform post-processing on the aluminum veneer, including polishing, cleaning, inspection, and other processes. This step can further improve the surface quality and service life of aluminum veneer.

High quality roller coated ceiling aluminum veneer requires strict production processes and quality control procedures. Only in this way can we ensure that the quality and performance of the product reach its optimal state. In the future, with the development of technology and continuous improvement of production processes, it is believed that roller coated ceiling aluminum veneer will have a wider range of application prospects.

Customer service QQ

Customer service QQ