Industry information

Company News

- Punched aluminum veneer: the fashionable choice for modern architecture?

- Carved aluminum veneer: the finishing touch of modern architecture

- Craftsmanship and the charming journey of carved aluminum veneer

- Punched aluminum veneer creates a fashionable and modern architectural style

- Customize aluminum veneer to create personalized spatial aesthetics

Industry dynamics

- Can aluminum veneer be used for building column design?

- Aluminum veneer has good impact performance

- What are the surface treatment techniques for aluminum veneer?

- What are the advantages and disadvantages of aluminum veneer compared to stone exterior walls?

- Carved aluminum veneer: a perfect fusion of art and craftsmanship

Frequently asked questions

- How to improve the fire resistance of aluminum veneer?

- How to determine the quantity and size of customized aluminum veneer?

- How to identify the quality of aluminum veneer?

- How to use aluminum veneer for innovative design?

- How to design customized aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

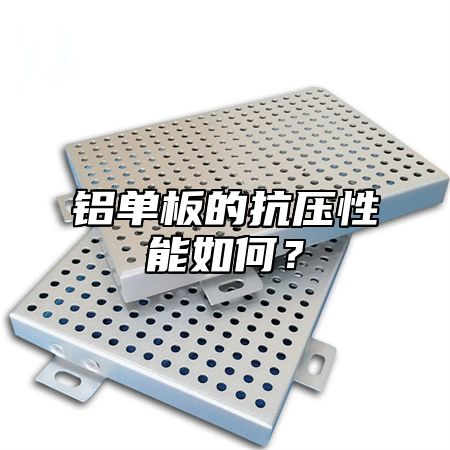

What is the compressive performance of aluminum veneer?

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: 2022-03-05 07:11:43

- Click:0

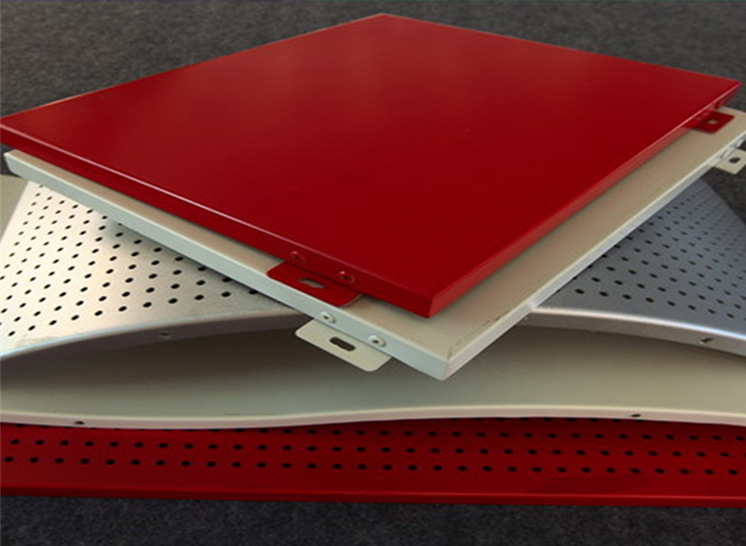

Aluminum veneerIt is a commonly used building material, and its compressive performance is one of the important indicators for evaluating its quality and effectiveness. The compressive performance of aluminum veneer mainly depends on factors such as its material, thickness, and surface treatment.

The material of aluminum veneer has a significant impact on its compressive performance. Generally speaking, pure aluminum has poor compressive performance, while alloy aluminum has better compressive performance. For example, aluminum alloys such as 6061 and 7050 have good strength and hardness, and can withstand significant pressure and impact forces. When choosing aluminum veneer, attention should be paid to the quality and type of its material.

The thickness of aluminum veneer is also an important factor affecting its compressive performance. Generally speaking, the thicker the aluminum veneer, the better its compressive performance. This is because increasing the thickness can improve the cross-sectional area and moment of inertia of aluminum veneer, thereby enhancing its ability to resist pressure. However, excessive thickness of aluminum veneer will increase weight and cost, so it needs to be selected according to specific needs.

The surface treatment of aluminum veneer also has a certain impact on its compressive performance. For example, anodizing treatment can form a hard oxide film on the surface of aluminum veneer, thereby improving its wear resistance and corrosion resistance, and also helping to enhance its compressive performance. In addition, some special surface treatment methods such as spraying, electrophoresis, etc. can also improve the surface quality and compressive performance of aluminum veneer.

The compressive performance of aluminum veneer is one of the important indicators for evaluating its quality and performance. When selecting aluminum veneer, it is necessary to comprehensively consider factors such as material, thickness, and surface treatment to ensure that it can meet practical needs and has a good service life and safety. It is recommended to choose products produced by legitimate manufacturers and pay attention to product inspection and acceptance work to ensure product quality and safety.

Customer service QQ

Customer service QQ