Industry information

Company News

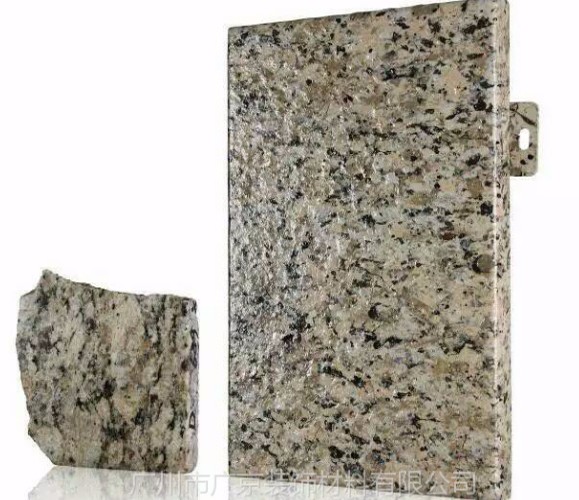

- Customized aluminum veneer, creating an artistic journey of personalized space

- Fluorocarbon aluminum veneer: the hidden champion of fashionable architecture

- Aluminum veneer customization, creating a new trend of personalized space

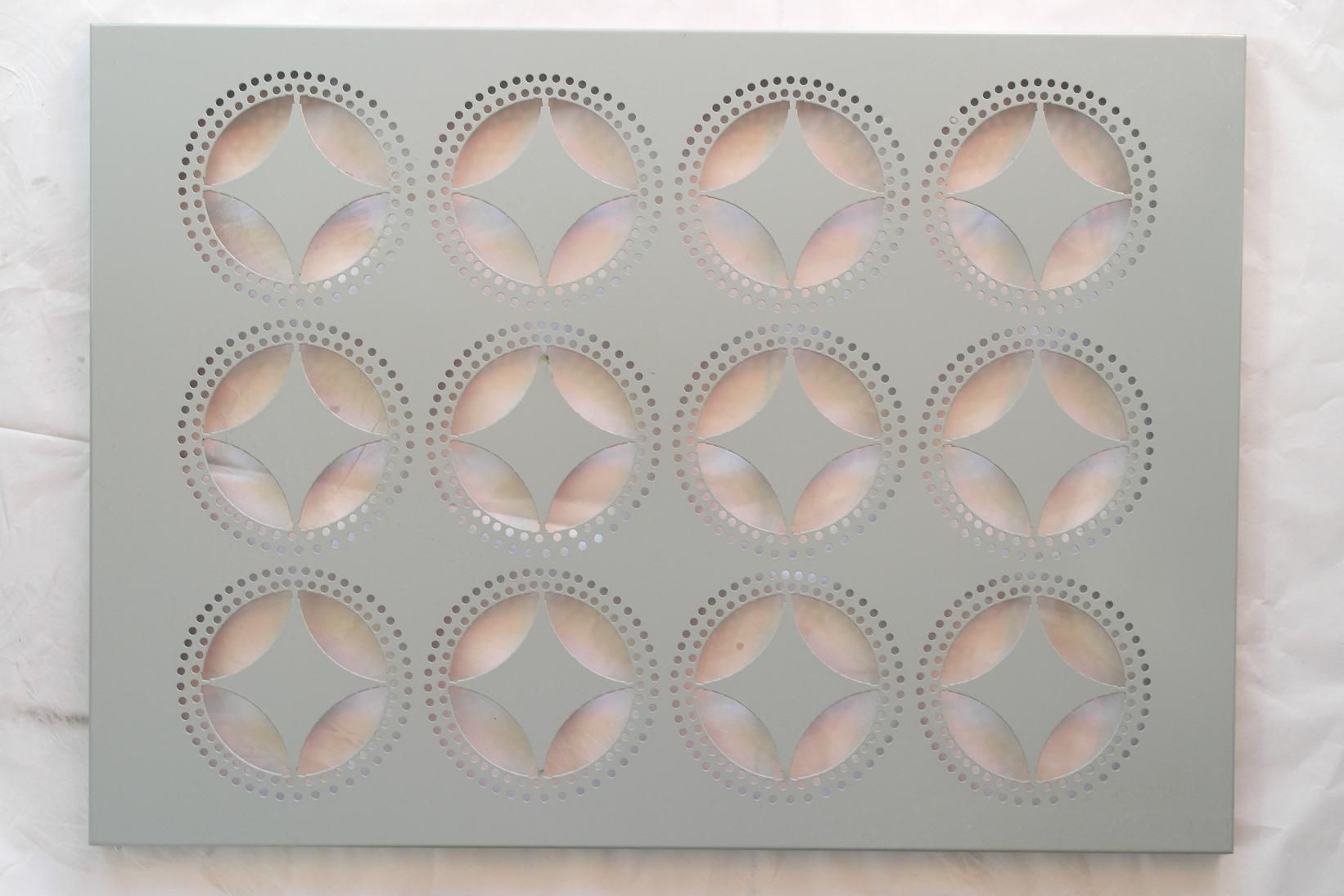

- Carved aluminum veneer: a delicate interpretation of architectural aesthetics

- Ancient charm and modern style, carved aluminum veneer, magnificent transformation of modern architecture

Industry dynamics

- Aluminum veneer customization, creating a new trend of personalized space

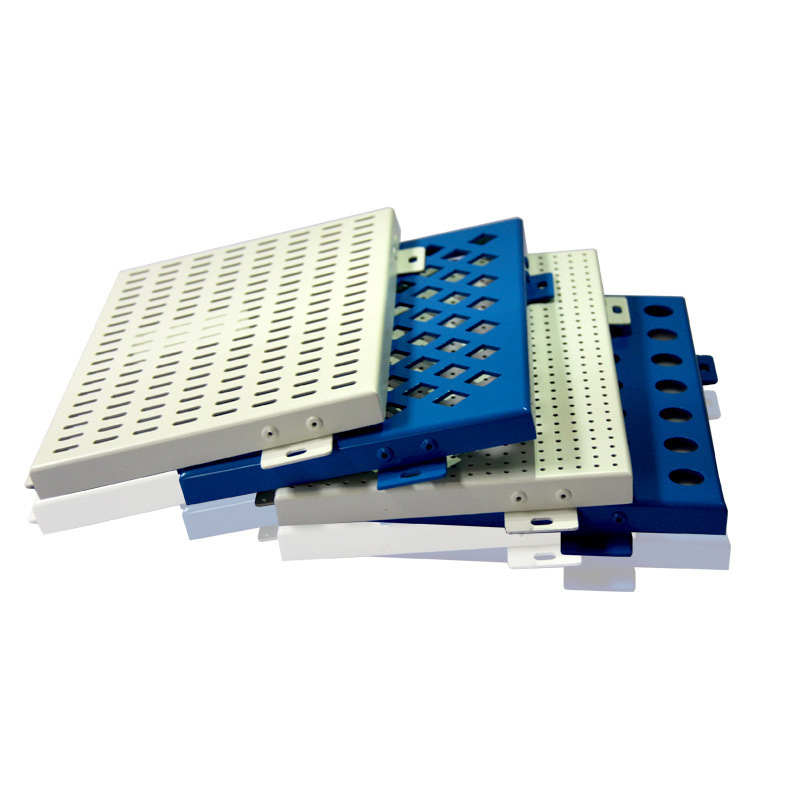

- The Fashion Journey of Punched Aluminum Veneer: Exploring the Beauty of Architecture

- Aluminum veneer customization service: meeting customers' personalized taste

- Carved aluminum veneer, a perfect fusion of art and technology

- Is the maintenance frequency of aluminum veneer high?

Frequently asked questions

- How to solve the environmental problems in the production process of aluminum veneer?

- How to identify the quality of aluminum veneer?

- How to improve the insulation performance of aluminum veneer?

- How to design customized aluminum veneer?

- How to improve the fire resistance of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Detailed explanation of aluminum veneer installation technology

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: 2022-02-26 16:19:39

- Click:0

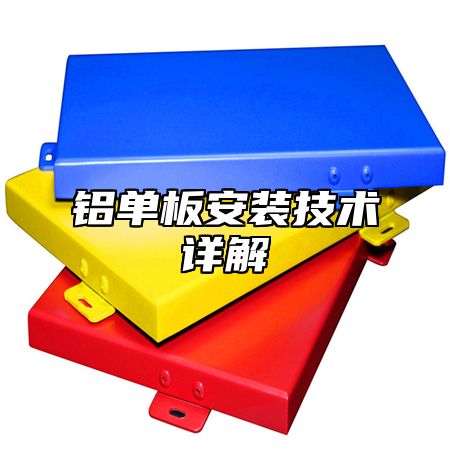

Aluminum veneerAs a lightweight and high-strength building material, it is widely used in fields such as building curtain walls and interior decoration. The installation technology of aluminum veneer has a crucial impact on its effectiveness and lifespan. This article will provide a detailed introduction to the selection, measurement, processing, and installation of aluminum veneer, helping readers understand the installation technology of aluminum veneer.

1、 Material selection of aluminum veneer

When choosing aluminum veneer, the following aspects need to be considered:

1. Material: Aluminum veneer is generally made of pure aluminum or alloy aluminum materials, among which 3003, 5052, etc. are commonly used alloy materials.

2. Thickness: The thickness of aluminum veneer is generally between 1.5mm-3mm, and different thicknesses of aluminum veneer are suitable for different occasions.

3. Surface treatment: Common surface treatment methods include anodizing, fluorocarbon spraying, etc. Different surface treatment methods can affect the corrosion resistance and appearance of aluminum veneer.

2、 Measurement and processing of aluminum veneer

Before installing aluminum veneer, precise measurement and processing are required. The specific steps are as follows:

1. Measurement: Measure the dimensions of the aluminum veneer based on the design drawings and actual site conditions, including length, width, height, etc.

2. Processing: Based on the measurement results, cut and slot the aluminum veneer for subsequent installation work.

3、 Installation of aluminum veneer

The installation of aluminum veneer requires the following steps:

1. Determine installation location: Based on the design drawings and actual site conditions, determine the installation location and direction of the aluminum veneer.

2. Fixed skeleton: Install keel or aluminum alloy skeleton on the wall or ceiling, and fix it in the appropriate position with screws.

3. Installation of support components: Install support components on the keel or aluminum alloy skeleton to support the aluminum veneer.

4. Installation of aluminum veneer: Install the processed aluminum veneer according to the requirements of the design drawings, paying attention to maintaining horizontal and vertical alignment.

5. Sealing treatment: Seal the joints of aluminum veneer to prevent rainwater, wind and sand from entering.

4、 Precautions

During the installation process of aluminum veneer, the following issues need to be noted:

1. Ensure accurate measurement: Measurement errors can cause uneven installation of aluminum veneers, affecting aesthetics and service life.

2. Ensure machining accuracy: Insufficient machining accuracy can lead to uneven interfaces of aluminum veneer, affecting the sealing effect.

3. Ensure secure installation: Loose installation can easily cause the aluminum veneer to fall off or deform, affecting its effectiveness and safety.

Customer service QQ

Customer service QQ