Industry information

Company News

- Carved aluminum veneer: a magnificent turn of aluminum art

- Carved aluminum veneer: artistic embellishment in modern architecture

- Aluminum veneer: the fashionable "coat" of modern architecture

- Aluminum veneer: a fashionable choice in modern architecture

- Fluorocarbon aluminum veneer: the new darling of modern architecture?

Industry dynamics

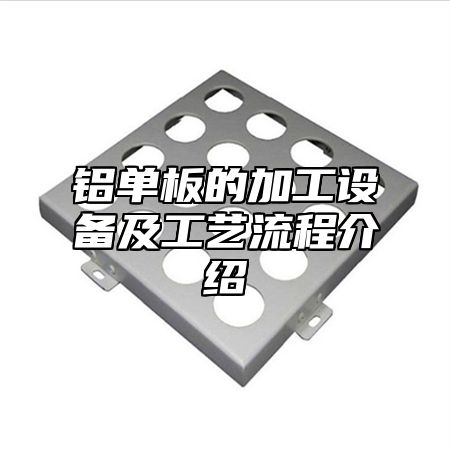

- Introduction to processing equipment and process flow for aluminum veneer

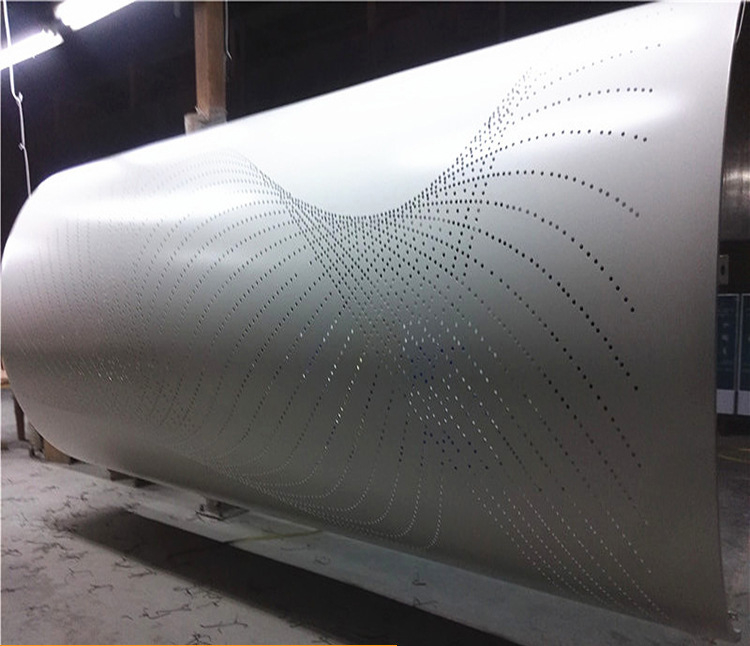

- Carved aluminum veneer: the unique charm of architectural art

- Aluminum veneer customization: an artistic journey to create personalized spaces

- Hollow out 2.5mm aluminum veneer for light luxury

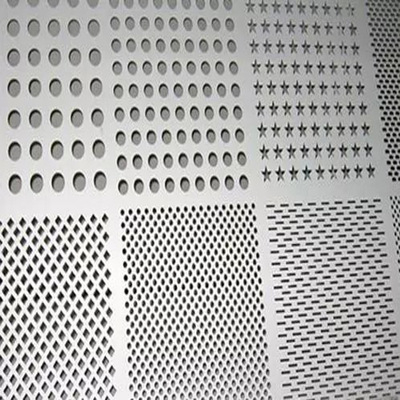

- Punched aluminum veneer: an innovative choice in architectural aesthetics

Frequently asked questions

- How to use aluminum veneer for innovative design?

- How to improve the fire resistance of aluminum veneer?

- How to use and maintain aluminum veneer reasonably?

- How to solve the environmental problems in the production process of aluminum veneer?

- How to improve the insulation performance of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Introduction to processing equipment and process flow for aluminum veneer

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: 2022-03-02 19:43:42

- Click:0

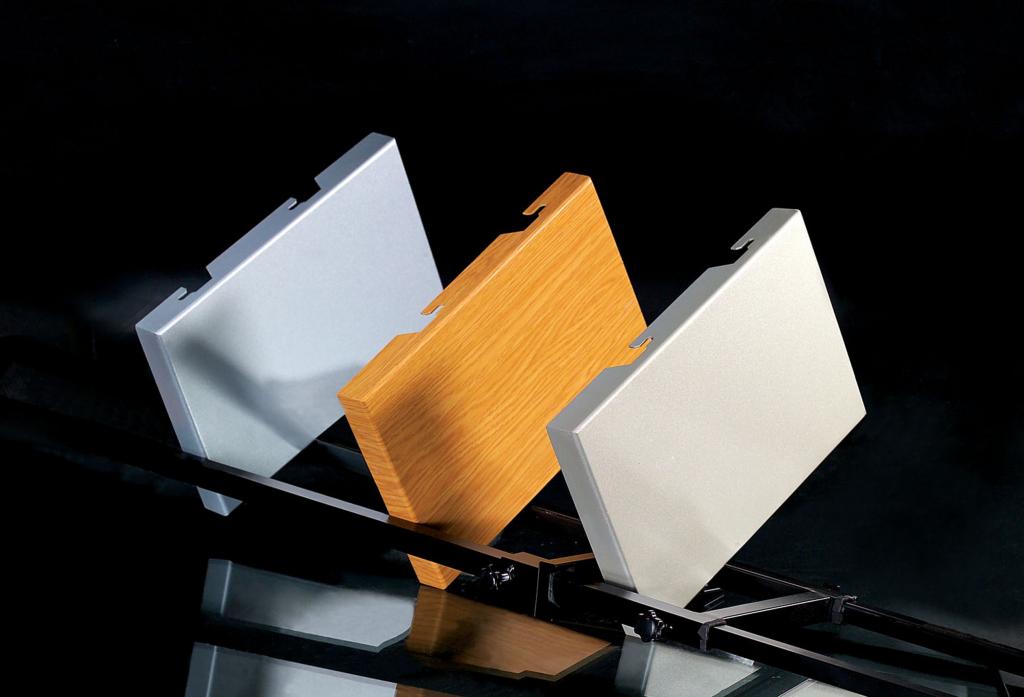

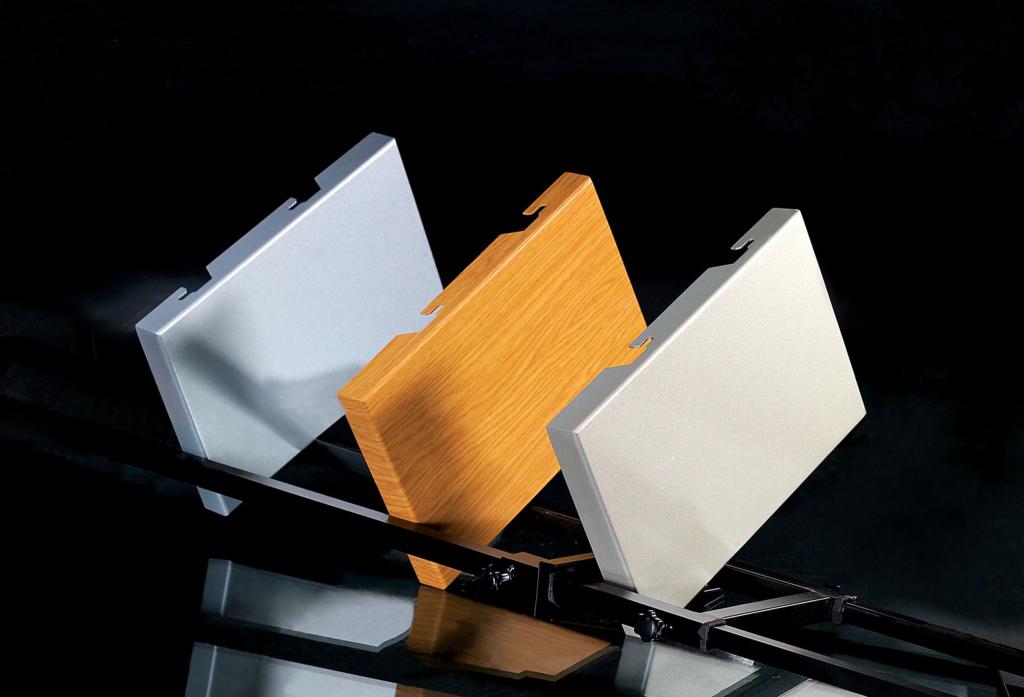

Aluminum veneerIt is a widely used building material with advantages such as light weight, high strength, and corrosion resistance. In the production process, professional processing equipment and technological processes are required to ensure product quality and production efficiency. This article will introduce the processing equipment and process flow of aluminum veneer.

1、 Processing equipment

1. CNC machine tool: CNC machine tool is a high-precision and high-efficiency processing equipment that can achieve precise cutting, engraving, bending and other processing operations of aluminum veneer.

2. Punch press: Punch press is a commonly used mechanical pressure processing equipment that can perform punching, bending, and forming operations on aluminum veneer.

3. Spray line: A spray line is an efficient surface treatment equipment that can perform surface treatment operations such as spraying and baking paint on aluminum veneers, improving their aesthetics and anti-corrosion performance.

2、 Process flow

1. Raw material preparation: Firstly, it is necessary to prepare aluminum coils and various auxiliary materials such as sealant, corner codes, etc.

2. Cutting: Cut the aluminum coil into the required size and shape according to the design requirements.

3. Punching: Use a punch press to punch aluminum veneer to meet different installation requirements.

4. Bending: Use CNC machine tools or mechanical presses to bend aluminum veneers to achieve different shaping effects.

5. Molding: Bending, embossing, and other molding operations are performed on aluminum veneers to achieve specific decorative effects.

6. Surface treatment: Spray coating, baking paint and other surface treatment operations are carried out on aluminum veneer to improve its aesthetics and anti-corrosion performance.

7. Quality inspection: Conduct quality testing and inspection on the processed aluminum veneer to ensure that the product meets the design requirements and quality standards.

3、 Precautions

1. Safety measures: During the processing, it is necessary to pay attention to safety measures, such as wearing protective equipment and avoiding machine injuries.

2. Environmental control: The processing process needs to maintain a dry and well ventilated environment to avoid the aluminum veneer being affected by moisture or other pollution factors.

The processing equipment and process flow of aluminum veneer are key factors in ensuring product quality and production efficiency. Attention should be paid to safety measures and environmental control during the production process to ensure smooth completion and high-quality products.

Customer service QQ

Customer service QQ