Industry information

Company News

- Aluminum veneer customization, creating a new proposition for personalized space!

- Fluorocarbon aluminum veneer: the fashionable choice for modern architecture?

- Aluminum veneer customization, creating a new trend of personalized space

- Punched aluminum veneer: the new trend of aluminum materials and the secret weapon of architectural aesthetics

- Carved aluminum veneer, the magnificent "cloak" of modern architecture

Industry dynamics

- Quality assurance for customized aluminum veneer: strict quality standards to create excellent quality

- Sharing of installation techniques for engineering fluorocarbon aluminum veneer

- Will the use of aluminum veneer affect the sound insulation effect of buildings?

- Punched aluminum veneer: a fashionable choice for modern architecture

- Punched aluminum veneer: the new darling of creative space, lightweight and fashionable!

Frequently asked questions

- How to store and transport aluminum veneer?

- How to improve the fire resistance of aluminum veneer?

- How to use and maintain aluminum veneer reasonably?

- How to distinguish the quality of aluminum veneer?

- How to use aluminum veneer for innovative design?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

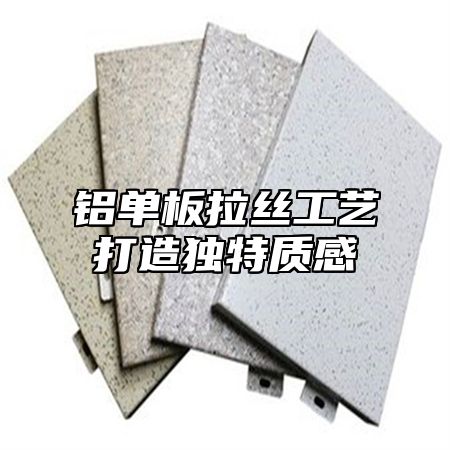

Aluminum veneer drawing process creates a unique texture

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: February 25, 2025 00:25:17

- Click:0

Aluminum veneerWire drawing process is a common surface treatment method that can bring unique texture and appearance to aluminum veneer. Let's take a detailed look at the principles and advantages of this process.

1、 The principle of wire drawing technology

Wire drawing technology is the process of processing the surface of aluminum veneer through mechanical equipment, creating a texture and luster similar to that of metal wire. Specifically, the wire drawing process uses a high-speed rotating grinding wheel or drill bit to form a layer of extremely fine metal particles on the surface of aluminum veneer, and then grinds these particles flat through mechanical grinding, ultimately forming a surface effect with a unique texture.

2、 The advantages of wire drawing technology

1. Beautiful and high-end: After the wire drawing process, the surface of the aluminum veneer presents a delicate and shiny effect, making it more beautiful and high-end.

2. High strength: After being treated with wire drawing technology, aluminum veneer will form a hard oxide film on its surface, thereby improving its corrosion resistance and anti-corrosion properties.

3. Strong wear resistance: The surface hardness of aluminum veneer treated by wire drawing process is high, which can withstand significant friction and wear.

3、 Application scenarios

The aluminum veneer processed by wire drawing technology is widely used in fields such as architectural decoration and electronic product casings. Especially in high-end commercial buildings, luxury residential decoration, as well as high-end manufacturing fields such as automobiles and aerospace, aluminum veneer processed by wire drawing technology has become an important decorative material.

4、 Precautions

When using aluminum veneer, the following points should be noted:

1. Pay attention to the material: First, confirm whether the selected aluminum veneer meets the quality standards and whether there are relevant certification certificates.

2. Pay attention to size: During installation, pay attention to whether the size of the aluminum veneer meets the design requirements to avoid gaps or unevenness.

3. Pay attention to maintenance: Regularly clean and maintain the aluminum veneer during use to maintain its appearance and performance.

Customer service QQ

Customer service QQ