Industry information

Company News

- Punched aluminum veneer: the "breathing window" of modern architecture

- New fashion favorite of aluminum plate: Exploring perforated aluminum veneer

- Aluminum veneer punching, unlimited creativity, new space proposition!

- Aluminum veneer customization, creating a new trend of personalized space

- Carved aluminum veneer: the delicate beauty of modern architecture

Industry dynamics

- The fashion evolution of aluminum veneer: not just building materials, but also attitude towards life

- What issues should be noted during the installation process of aluminum veneer?

- Fluorocarbon aluminum veneer: a rising star in aluminum materials and a fashion darling in the construction industry

- Wood grain ceiling aluminum veneer creates a natural and comfortable space environment

- The Charm of Aluminum Veneer: The "Face saving Project" of Modern Architecture

Frequently asked questions

- How to determine the quantity and size of customized aluminum veneer?

- How to solve the environmental problems in the production process of aluminum veneer?

- How to identify the quality of aluminum veneer?

- How to improve the fire resistance of aluminum veneer?

- How to use and maintain aluminum veneer reasonably?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Punched aluminum veneer: a unique interpretation of architectural aesthetics

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: February 28, 2025 21:34:06

- Click:0

Dear architectural aesthetics enthusiasts, today let's talk about a magical material - punchingAluminum veneerYou may think it's just too ordinary, but don't underestimate it, it's an indispensable "beauty responsibility" in modern architecture!

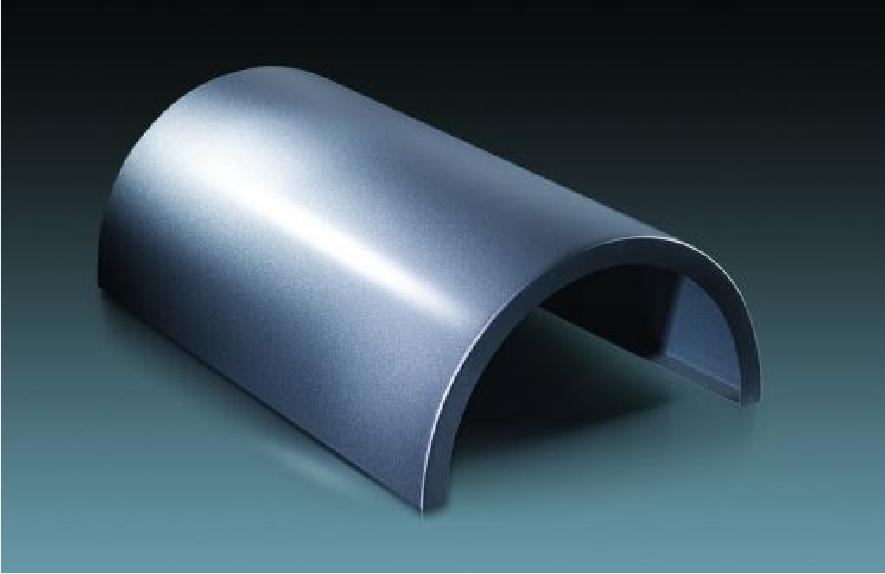

Let's talk about what this punched aluminum veneer is. It is a building material that is both beautiful and practical, made by punching holes in an aluminum plate and then undergoing a series of complex processing techniques. It sounds a bit complicated, but in fact, it's like a "transformation device" that can make ordinary aluminum plates shine with a different kind of brilliance.

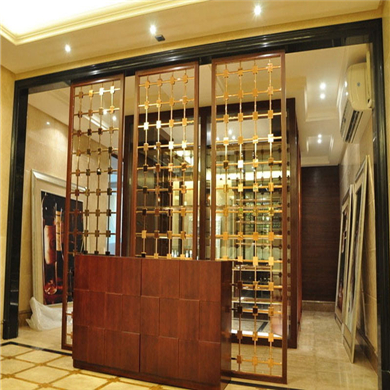

Let's first talk about the "appearance" of punched aluminum veneer. Do you know why many high-end buildings like to use it? Because it can create unique visual effects. Imagine sunlight shining through holes on a building, and the scene is as beautiful as a painting. Punched aluminum veneer also has various hole types to choose from, ranging from circular, square to irregular, all of which can meet your personalized needs.

Of course, punching aluminum veneer is not just for aesthetics. It also has many practical functions. It has good weather resistance and can maintain stability in various harsh environments. It can handle wind and rain, as well as sun and rain, with ease. This means that buildings decorated with punched aluminum veneer have a longer lifespan and lower maintenance costs.

Another point is that perforated aluminum veneer also has good sound and heat insulation effects. In the scorching summer, it can effectively block outdoor heat from entering indoors, allowing you to enjoy a cool and comfortable living environment. In the cold winter, it can prevent indoor heat loss and keep you warm like spring.

Speaking of which, I remembered a story. Once upon a time, there was a designer who traveled throughout the city in search of a building material that could meet both the aesthetic needs of architecture and practical functionality. He chose perforated aluminum veneer. Under the skillful hands of the designers, these buildings seem to have put on a "gorgeous coat" and become a beautiful scenery in the city.

How is punched aluminum veneer made? It goes through multiple stages such as material selection, punching, polishing, and coating. In this process, every step is crucial, and even a slight mistake can affect the final outcome.

Material selection. High quality aluminum alloy sheets are usually selected for punched aluminum veneers because aluminum alloys have excellent processing performance, corrosion resistance, and strength. When selecting materials, it is necessary to ensure that the thickness, material, and surface treatment of the board meet the requirements.

Punching. This is the most crucial step in the production process of punched aluminum veneer. According to the design requirements, holes are punched on the aluminum plate using professional punching equipment. The size, shape, and distribution of holes can all affect the final visual effect. This step requires experienced technicians to operate.

polish. After punching, it is necessary to polish the periphery of the hole to make it smooth and even. This step can improve the aesthetics and ensure that the board is not easily damaged during installation.

Coating. In order to improve the weather resistance, corrosion resistance, and decorative properties of punched aluminum veneer, a protective film is usually coated on the surface. This protective film can effectively isolate the damage of the external environment to the board and extend its service life.

Punched aluminum veneer is a building material that combines aesthetics, practicality, and environmental friendliness. It can not only add unique beauty to buildings, but also improve their comfort and service life. In this era of pursuing personalization, it is believed that punched aluminum veneer will become increasingly popular among architects.

I have a question for everyone: Have you ever seen a building decorated with punched aluminum veneer? What do you think of this material? Welcome to leave a comment in the comment section to share your opinions!

Customer service QQ

Customer service QQ